Five Key Elements in Completing and Delivering a Building to Expectations

Assurance that a building is delivered and performs as designed (and meets owner’s expectations) when occupied, is a popular response to the question as to why an owner contracts for commissioning services. The quality assurance function of reviewing, verifying, and documenting each step in the design and construction process is, in essence, “commissioning” which will document the final status of the building systems delivered. The problem is that most buildings are “delivered” in stages: Substantial Completion, Occupancy, Final Completion, and the time line of these stages can vary widely.

This paper will describe the completion stages of a 420,000 square foot laboratory building and focus on the five key elements of building construction completion:

installation, start-up, control, balance, and performance verification.

The paper will delve into the relationship and resulting impact of the overlap of these five completion elements with the three stages of completion, as well as the resulting benefit to having commissioning as part of the process.

Introduction: Expectations vs. Reality

To occupy a building that has been functionally completed with all components and systems fully installed, started, controlled, balanced, and tested upon occupancy seems to be a reasonable owner’s expectation and goal when commencing a new construction project.

The owner’s design team builds this expectation into the project contract requirements in the form of the project specifications, which along with the design drawings become the project contract documents.

The construction team agrees to fulfill the intent of the contract documents and creates a project schedule that reflects both the contract document requirements and owner’s occupancy requirements. It should be noted that an owner’s occupancy expectation and construction team schedule might include a phased occupancy based on owner needs and the construction practicality of meeting those needs. In any event, the construction schedule normally includes the start and completion of all facets of the physical construction requirements prior to the occupancy target.

Therefore, the owner upon signing the construction contract has essentially secured a “promise” that the construction team will deliver the building depicted in the contract documents1, with the expectation of construction completion prior to occupancy. Unfortunately, it is rare that contract conformance and owner occupancy are completed simultaneously as planned.

Stages of Completion

EH&E’s experience is that most buildings are occupied prior to all systems being complete. It should also be noted that there is a difference between systems being operational and systems performing to their final design requirements. Therefore, it’s important to discuss the various stages of construction completion:

Substantial Completion, Occupancy, and Final Completion.

Substantial Completion

The definition of substantial completion will vary, depending on perspective of the general contractor and the building owner.

General Contractor – In the latter stages of the construction project, the focus of the construction team is on securing the Certificate of Occupancy (C of O) and the GC generally considers that the project is substantially complete when the C of O is secured. Generally, the requirement for a C of O is that all major equipment is in place and operational and all architectural elements and finishes are complete. The key items for sign-off by the jurisdictional authority to issue an occupancy permit are life safety, power, and ventilation.

Owner — In most cases, the owner would also say that "substantial completion" is attained when the certificate of occupancy is acquired. The owner’s thought process normally appears to be that when the building is “functional” and acceptable to the local code officials having jurisdiction, then the building is substantially complete and all outstanding issues become “punch list” items.

An additional owner expectation associated with substantial completion is that all training and operations and maintenance (O&M) manual requirements be contractually completed. The importance of thorough staff training on all building elements and systems as well as complete O&M manuals cannot be underestimated. It is imperative that clarity of system design and proper maintenance protocols are transferred to the owner’s staff, if optimum performance is to be sustained over the life of the project.

(Note: Although this knowledge transfer cannot be underestimated in relation to building and system performance after occupancy, this paper is primarily focused on issues related to the physical construction completion. Therefore, training and O&M will not be further addressed.)

Commissioning Engineer — Substantial completion is attained when all of the following have been completed:

1. All architectural elements and functions have been completed.

2. All contractual obligations for equipment and system installation of the mechanical, electrical, plumbing, life-safety, and fire protection systems iscompleted, inclusive of:

a. Equipment installation – 100%.

b. Equipment start-up, including completed start-up reports.

c. Controls completion, including completed “point-to-point” check-out

sheets.

d. Complete air and water system balancing reports.

Since commissioning is essentially an “acceptance process,” inherently commissioned systems need to be “complete” with limited and defined punch list issues. There is credence to all three perspectives. In some cases all three perspectives are in alignment, i.e., all prerequisites for the commissioning acceptance process are fulfilled at the time the C of O is issued. However, on large, complex projects this is usually not the case.

Occupancy

As discussed in relation to the acquisition of an occupancy permit, certain tangible aspects of the building must be complete prior to occupancy, but intangible contractual deliverables such as air and water balancing, final and optimal system control, staff training, and document transfer to the owner’s staff may not be complete.

Unfortunately, in many cases, an owner’s occupancy schedule includes constraints that do not allow for additional time required by construction delays, regardless of the reason for those delays. Performance shortfalls, such as insufficient air distribution to certain end-use spaces or failed reheat coil operation, could easily go undetected prior to occupancy, but will contribute to excessive maintenance calls upon occupancy.

However, blatant failures will be noticeable, while performance shortfalls such as inadequate air or water flow may not be as easily detectable under certain load conditions. Also, system completion will generally cause disruptions and complaints from the occupants due to potential system isolation and/or shutdowns during occupied hours.

System “final” is a milestone signifying that the system is 100% installed,

started, controlled and balanced, and ready for owner acceptance.

When the opportunity exists, it’s important to complete and commission all aspects of a system prior to occupancy to ensure designed performance.

Occupancy prior to system completion will risk:

- Generating occupant complaints.

- Disruptions to the occupants while work is being completed.

- Never fully completing the system that was contracted for.

- Occupant perception of the new facility as a “bad building.”

Final Completion

System “final” is a milestone signifying that the system is 100% installed, started, controlled and balanced, and ready for owner acceptance. All known punch list items should be complete. In actuality, the term “final completion” is redundant. The fact that final completion is normal jargon on construction projects is a good indicator of the complications system completion presents.

Reality of Occupancy Needs Spurs Modifications

Most building systems are not complete upon occupancy, mainly because they can be occupied without being “complete,” as previously described. As “beauty is in the eye of the beholder,” so too is “completion in the eye of the needy,” with “needy” defined as “those with a specific occupancy requirement.” Something short of complete, but perceived as “close” to complete becomes acceptable when an occupancy date is immovable.

Unfortunately, most building system performance shortfalls will become evident upon or during occupancy. An occupant will be exposed to heating or cooling deficiencies, and any anomalies related to power, lighting, process, or thermal comfort (i.e., anything that they can physically sense).

Technically, if a system is not complete, it’s not ready to be commissioned (performance/acceptance tested). However, to avoid the building owner being inundated with complaints upon occupancy of a building with incomplete and untested systems, we will modify the commissioning scope and process to test “move-in” status of systems and room conditions. This scope modification is intended to improve system reliability for the building occupants by identifying system shortfalls existing under the move-in conditions.

My experience in Massachusetts is that the applicable municipal inspectors are fairly stringent in their sign-off requirements for electrical, fire alarm, fire protection, and life-safety systems. These inspectors request necessary documentation and witness system demonstrations of specific building systems. The “sign-off” of these officials is essential in getting the owner a building occupancy permit or at least a conditional “temporary occupancy permit” pending the completion of specific corrective or completion issues.

HVAC Considerations

What does not currently fall into the category of a municipal official’s final “signoff” is the building’s heating, ventilating, and air-conditioning (HVAC) system, except where these systems are an integral part of those systems requiring municipal jurisdictional sign-off such as the ventilation required for stair pressurization or smoke evacuation where applicable.

So, from the contractor’s stand-point, the building is “substantially complete” when the occupancy permit requirements have been met. Most owners generally agree, with the understanding that the “punch-list” will be completed.

However, from a commissioning perspective, Substantial Completion would require that all components and subsystems of the HVAC system be documented that they have been completed, started, fully controlled and balanced per the building’s design intent and contract documents.

Commissioning is a process of quality assurance steps that ultimately documents that equipment and systems meet the requirements of the construction “contract documents:” plans, specifications, and all formally accepted changes. In essence, the commissioning process is an “acceptance” process which inherently would require that building systems are complete (you wouldn’t knowingly accept a system that is not complete). The larger point here is that systems might be

operational but not complete in that these systems may not be meeting the performance requirements specified in the contract documents. For example the performance of an air handling unit (AHU) is dictated by the completion

requirements of every element of the air handling system:

- Design and specification

- Purchase

- Manufacture

- Installation

- Ductwork integration

- Piping integration

- Fan start-up

- Controls Integration

- Air distribution system completion

- Architectural room level completion

- Final air and water balancing.

Prior to final controls completion, the air handler may be delivering air quantities to the building but performance functions such as variable volume supply & return, economizer, and face and bypass control may not be performing as designed.

Prior to final system balancing, the air handler is operational but the zones being serviced might be getting uneven air distribution, “hot/cold” spots, or pressurization issues. In these two examples the air handling unit is operational, but far from finished. Until completed, the building in most cases will experience problems and occupant complaints, regardless of the existence of a building permit.

The Five Key Elements to Completion

Exclusive of design and project turnover requirements, there are five key elements to an HVAC system completion during the project’s construction phase with each element being the precursor to the next. They are:

- Installation

- Start-up

- Control

- Balance

- Performance verification

Commissioning applies a process of review, verification, and documentation that the “final product” conforms to the project design requirements in every way. It should be understood that the “final product” is developed and constructed in layers over time in an “uncontrolled” or “discontinuous” environment.

Commissioning is most effective when applied to all construction phases or “layers” with an “inchstone” mentality to ensure that by the time of system acceptance, individual components have been “debugged” and that system testing is being performed on a system of “bugless” parts.2,3

I’ve attempted to best review these five basic elements to construction completion by benchmarking the intent and expectation of each element against the field reality experienced on commissioning a 420,000 sq.ft. laboratory/research building, inclusive of recently-completed, 50,000 sq.ft. animal facility.

The back-up data described is the result of the project contract documents, construction schedules, commissioning schedules, meeting minutes, and commissioning action lists. As background, the commissioning scope included HVAC, electrical, plumbing, and life safety systems.

1. Installation

Construction installation should be straightforward based on the product specified, approved, and installed per manufacturer, code, and design requirements. Completion verification becomes the biggest issue with installation from both a contractual as well as a quality assurance “process” basis. As referenced earlier, each element in the construction completion process is a precursor to the next. From a construction perspective the biggest factor impacting the installation and schedule were project changes.

From a commissioning perspective adherence to the contract documents and code compliance are the largest producers of commissioning action list items. In fact, there were 389 issues cited (50% of the project total of 780) during installation,

running the gamut from materials (different than approved), installation technique (material supports), installation incompletion (missing piping insulation), and missing equipment/accessories (air dampers, vibration isolators, seismic restraints). It should be clarified that as standard protocol, EH&E does not enter an item onto the commissioning action list if the installation is obviously still in the process of completion unless the material or application being used is an apparent code violation. From an operational perspective, few, if any, of these items would keep a building from functioning if left undetected, but all would have had an impact on the value and ultimate performance of the building.

From a quality assurance process perspective an incomplete product installation may have an impact on a subsequent completion stage (i.e., missing volume dampers will undoubtedly impact system air balancing).

2. Start-up

Upon assurance that equipment and accessories are installed per the contract requirements, equipment start-up is critical. Proper start-up ensures performance, longevity, and warranty. Improper or absence of proper manufacturer established start-up procedures will jeopardize the equipment integrity and almost always lead to: operational issues, sub-par performance, reliability and/or premature equipment failure, increased maintenance staff time, and warranty issues.

The following is the start-up requirement for the main air handling units on our laboratory building example as listed in the project specification:

“Unit Manufacturer’s Representative / Start-Up Services: Each individual unit interior and exterior shall be inspected and reviewed by the unit manufacturer’s representative, before start-up. The unit manufacturer shall supervise the installation of final filters, the removal of all component shipping blocks, removal of any and all interior and exterior cleanliness protection, and the removal of any duct covering protection. Units shall then be started-up by the unit manufacturer in conjunction with the contractor. Start-up shall include run testing the fan, and confirming the vibration parameters, etc., of the fan assembly, all per submitted test procedures. The unit manufacturer shall submit a written start-up report to the architect.”

The specification details a series of steps or “quality assurance process” required prior to initial operation of the air handling unit which includes: the parties involved; start-up prerequisites; start-up requirements; and written report requirements.

Appropriate equipment start-up ensures that both surrounding conditions and integral system parts associated with the air handling unit meet the applicable factory, code, and specification requirements. When all start-up requirements are met and documented, the construction team can proceed to subsequent completion elements with a level of confidence that contract requirements have been met to that point.

Although the quality assurance that formal start-up procedures provide should never be compromised, the process of scheduling start-ups for all equipment is far from a simple construction task. The reality of the construction site is that start-ups are driven by system type, construction needs, and seasonal requirements. In an ideal and “controlled” construction scenario, all start-ups would have a similar place in the schedule in relation to construction installation completion and could be approached as a “milestone” with all parties on the same page related to start-up schedule as a precursor to final system controls and balancing.

On our lab project, equipment start-up lasted almost one year. Many air handling units and heating systems supporting these air handling units were required for winter heating during construction, while the building wasn’t scheduled for completion until the following September. Also there’s always the temptation for the construction team to by-pass formal start-up procedures and team notifications due to their own schedule requirements and that of their vendors. Because of the long term ramifications a “failed” start-up might bring, this is a quality assurance “milestone” that owners insist not be compromised. Our laboratory project also contained the following language in the “materials and methods” section of the mechanical specification.

“The HVAC Contractor, as applicable, shall commission and set in operating condition all major equipment and systems, such as the condenser water, hot water and all air handling systems, etc., in the presence of the applicable equipment manufacturer’s representatives, and the Owner and Architect’s representatives. In no case will major systems and equipment be commissioned by any of the Contractor’s forces alone, without the assistance or presence of the equipment manufacturers.”

In terms of quality control, proper start-up should not be compromised, and in terms of value, a complete start-up as specified is an integral part of ultimate system performance.

3. Controls Completion

Although certainly an integral part of the system installation, controls completion needs to be addressed as a separate element and milestone due to the fact that incomplete controls may not prevent operation, but will absolutely impact system performance from both an equipment control as well as system

balancing perspective. Addressing controls issues also introduces a construction element where an incomplete installation is not easily detectable (or in most cases, not detectable at all) during a physical inspection. In fact deficiencies involving controls are usually discovered only as a result of balancing and/or

performance testing.

Attention is usually paid to the quality assurance aspect of controls installation and integration in the contract documents. The following is an excerpt from the “automatic temperature controls” specification for our lab building:

“Upon completion of the project, the Contractor shall:

1. Fine-tune and “de-bug” all software control loops, routines,

programs and sequences of control associated with the control

system supplied. Completely adjust and make ready for use, all

transmitters, relays, damper operators, valves, etc., provided under

this Section."

2. This Contractor shall furnish copies of complete, detailed,

calibrating checkout and commissioning documentation for each controller. Documentation shall list each procedure and shall be signed by the control specialist performing the service.”

In most cases, and specifically as it applies to this project, controls “commissioning” is the complete “point-to-point” check-out procedure as described in item 2 above. It is critical that each construction step (or element) deliver their required quality assurance requirements, but none is more critical to system performance than the implementation of a complete and thorough “point-topoint” check-out of the entire controls system.

The “point-to-point” check-out sheets complete with dates and signatures of the confirming controls technician is critical documentation as a prerequisite to balancing and testing. Incomplete controls check-out will ultimately lead to system balancing delays and system performance issues.

Owners should without exception demand the controls completion documentation for a system

(or at least a subsystem if schedule demands exist) prior to proceeding to balancing.

Owners should take note of the critical importance to completing one construction element prior to proceeding to the next. Owners should without exception demand the controls completion documentation for a system (or at least a subsystem if schedule demands exist) prior to proceeding to balancing.

Verification that controls integration is fully completed will lead to a more efficient balancing effort and help eliminate delays in the balancing schedule. Reality is that most often the “point-to-point” controls documentation is deliveredwith the “as-built” and/or O&M documents and not prior to the commencement ofbalancing. This was the case in our lab building despite the contract requirements and the many written and verbal requests during the commissioning process. Project quality assurance is jeopardized as a result.

4. Balancing

System air and water balancing represents the last construction phase completion element which is an integral part of system completion and is absolutely critical to system performance. However, like controls completion, the complete implementation of the contract balancing requirements is not easily

detectable without some method of measurement.

The main avenue to qualify balancing completion is testing, either by absolute measurements achieved by spot testing or as a product of system performance

testing. Normally the client settles for the delivery and approval (by the design team) of the final balancing report as proof of balancing completion.

In our laboratory building example, there were additional safeguards integrated into the balancing contract requirements which alluded to detailed requirements of the mechanical and controls contractors as prerequisites to the start of

balancing. In addition, the specification summarized the following:

"Balance and testing shall not begin until all HVAC systems have been completed and are in full working order, as determined by the Architect. Where construction is phased, the Testing and Balancing Contractor shallsubmit a plan of action which outlines how each phase will be balanced and how, when completed, the entire system will be verified to be tested and balanced. The Balancing Contractor shall coordinate his work with the HVAC and ATC Contractors, shall place all heating, ventilating and air conditioning systems and equipment into full operation, and continue the operation of same during each working day of adjusting and balancing.”

Again, adherence to the implementation and completion requirements of each construction element is essential. The quality assurance process requirements need to be addressed early and often during all construction and commissioning meetings and the owner needs to insist that the protocols outlined in the contract documents be followed. When any element is compromised the project becomes fertile for deficiencies and performance shortfalls.

- Air Handling Units

- Exhaust Air Handling Units

- Steam/Hot Water systems

- Chilled Water systems

- Animal Quarters.

The “move in” stage included primarily the “non-animal” laboratory and office spaces. There was a coordinated effort by the general contractor, controls contractor, balancer, and EH&E to systematically complete rooms based on the chronological move in schedule. Although not the best plan, this worked (to a point) based on the project status and owner occupancy requirement.

The “post move in” performance testing consisted of mainly testing equipment that was not deemed critical to be completed by the controls and/or balancing contractor in relation to the move in schedule.

It was agreed that performance verification of the overall building systems integration would be limited to performance trend data analysis upon final construction completion.

Laboratory Building Results

In the land of “best laid plans” the original construction schedule had allowed for two months for punch list and “commissioning” (performance testing) activities prior to owner occupancy. In April of 2005 it became obvious that due to the amount of owner initiated changes on this extremely equipment intensive project, and other construction and schedule related issues, that the completion schedule needed to be extended. However, the owner’s occupancy requirements

allowed for very little movement. The construction schedule was revised to reflect completion requirements prioritized based on both occupancy permit requirements and owner defined “critical” systems and spaces.

Along with the quality assurance and systematic process issues of each individual completion element already addressed, attention should be paid to the impact of completing building controls and balancing after occupancy. The

completion of system controls and balancing requires a certain amount of system “shut-downs” not all of which can be scheduled for “off hours.” Being a laboratory/research facility, this building essentially had no off hours.

The balancing process inherently requires systems to be placed into their maximum and minimum conditions. These conditions caused extreme temperature and system pressure swings impacting both comfort and laboratory

exhaust issues. Once the building was occupied, all “trouble” calls were channeled through the owner’s operations center. In addition, one of the biggest “occupancy” problems was the inherent air handler and fume hood (audible)

alarms that were being triggered by the balancing activity. The impact on the maintenance staff was burdensome, and this was driven predominantly by the fact that the building systems were not complete.

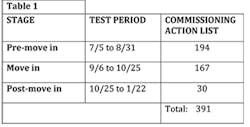

Also, this scenario created a situation where maintenance adjustments, especially those resulting from night and weekend trouble call responses, were impeding the balancing contractor’s completion efforts. From the perspective of performance testing, the majority of the commissioning action list issues identified during the pre-move in testing stage (194) as shown

in Table 1 were not addressed until after occupancy. The labor force was directing all efforts to meeting the requirement of securing an occupancy permit by September 1st. Occupants were hindered by issues related to construction

completion as well as documented deficiencies yet to be resolved.

Conclusions

The importance for owners to fully understand the elements of construction completion and the ramifications of completing tasks “out of order” is critical to ultimately ensuring that building systems perform as intended upon occupancy.

Our experience suggests the following recommendations to owners:

1. Add completion expectations to the Design Intent or Owner Project

Requirements.

2. Utilize commissioning documentation to benchmark completion status.

3. Require delivery of all successfully completed start-up reports

immediately, but no later than 5 days after completion.

4. Require completed controls “point-to-point” check-out sheets immediately,

but no later than 5 days after completion.

5. Enforce specification requirements.

6. Document for maintenance staff and building occupants all issues

involving completion impacts after occupancy.

7. Understand the ramifications of schedule impacts on final completion and

contract conformance.

References:

1 Project Management for Construction: Chris Hendrickson, Department of Civil and Environmental

Engineering, Carnegie Mellon University.

2 Kevin Kelly, "Out of Control," Addison-Wesley 1994.

3 “Dollar Value of Commissioning” M. Della Barba, National Conference on Building

Commissioning, 2005.