Ed. Note: Superheat and subcooling are among the most popular technical topics published in Contracting Business.com. Here, from one of the industry's leading experts on the subject, is a review of key superheat and subcooling concepts, for technicians to keep in mind as they venture into the field for a new cooling season.

Superheat

When a refrigerant is at its saturation point, the temperature of the liquid and vapor are the same. However, if additional heat is added to the vapor, the temperature of the vapor will increase. The temperature increase above its saturation temperature is called superheat.

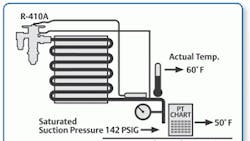

As an example, let's assume we have an R-410A operating system with an evaporator pressure of 142 psig. By checking the PT chart we’ll see that the saturation temperature is 50F (see Figure 1). Now, let’s measure the temperature of the suction line just after the evaporator coil. We find this temperature to be 60F. The difference between the actual temperature and saturation temperature in this example is, 60F-50F =10F; this 10F is the superheat.

By assuring we have superheat at the evaporator outlet we know several things about our system:

The expansion valve is operating as designed and controlling the superheat at the evaporator outlet.

Since there is superheated vapor at the evaporator outlet, we know that there will be no liquid refrigerant entering the compressor. This is important, since liquid entering the compressor can cause compressor damage due to oil dilution and/or in severe cases, liquid slugging.

Subcooling

When heat is removed from a saturated refrigerant, the temperature of the liquid is reduced. The difference between the saturated liquid temperature and the actual liquid temperature is the subcooled temperature.

Let's use an R-410A operating system in this example, where the condensing pressure is 295 psig. Again, checking the PT chart we'll see that the condensing temperature is 95F. Now, when we measure the temperature of the refrigerant leaving the condenser, we find it to be 85F. The difference between the condensing temperature and the actual temperature is 95F -85F =10F. In this example, we would say the refrigerant is subcooled 10F (see Figure 2).

For any system to operate properly there must be a solid seal of liquid refrigerant at the inlet of the expansion device. This is true of both thermal expansion valves (TXVs) and flow raters. By assuring a reasonable subcooled state at the outlet of the condenser, we know we have this solid liquid seal. Of course there are instances where the subcooled state will be lost. Excessive pressure drop in the liquid line caused by undersized components such as filter-driers or solenoid valves or flow restrictions of any type (kinked tubing) can create sufficient pressure drop to lose all the subcooling. An evaporator mounted higher than the condensing unit can also be a problem, because the liquid line pressure will drop as the refrigerant is "lifted" to the height of the evaporator. Subcooling can also be lost if the liquid line is run through an ambient space significantly warmer than the subcooled liquid. A hot attic is an example of such a condition.

If any of these conditions are encountered it's advisable to check the liquid line temperature and pressure at the inlet of the TXV to make sure a subcooled state is present.

Checking the Charge

In an air conditioning system with a fixed orifice as its expansion device, the amount of circulated refrigerant will depend on the ambient temperature. As the ambient temperature increases, the condensing pressure also increases, resulting in a higher pressure differential across the orifice. This will increase the flow rate of refrigerant in the system, resulting in less liquid remaining in the condenser and correspondingly lower subcooling.

Manufacturers of air conditioning systems use this principle to develop charts that show what the proper subcooling should be at different outdoor and indoor conditions. By referring to the chart, the technician can determine if the subcooling is higher or lower than the OEM specification. If the subcooling is too low, charge must be added to the system. Conversely, if the subcooling is too high, the system is overcharged, and some refrigerant must be removed.

On a system with a thermostatic expansion valve, the subcooling will not be affected very much by the ambient conditions. This is because at higher pressure differentials the TXV will close slightly to maintain the desired superheat. As a result, the subcooling will not change appreciably with the ambient. Subcooling can still be used to identify an over or under-charged system. Typical systems will run between 10F and 20F of subcooling. If lower than 10F, the system is likely undercharged. If over 20F, the system is probably overcharged. These "rules of thumb" are approximate. The technician should always follow the OEM guidelines, if available.

Subcooling is desirable because it increases the efficiency of an air conditioning system. However, too much subcooling will back liquid up in the condenser causing increased head pressures. This will cause the system to operate inefficiently and in extreme cases may cause the compressor to trip on its high pressure control or its internal protector.

Superheat and Adjusting TXVs

Ideally, the best way to check the operation of the TXV is to measure the superheat at the evaporator outlet. In many cases this is not convenient for the technician, since there may be no gauge ports available. A superheat check at the condensing unit can be used instead. Since suction line lengths can vary, so too can the superheat measured at the condensing unit. With short line lengths (less than 30 ft.), the superheat should be between 10F and 15F. With longer suction line lengths (between 30 and 50 ft.) superheats of 15F to 20F are normal.

If the superheat is too low, and an adjustable-type valve is supplied, the superheat can be increased by turning the adjustment stem in a clockwise direction. It's a good practice to wait for 15 to 20 minutes after adjusting the valve, to allow for the system to balance out before determining the effect of the adjustment. If the superheat is too high, it can be lowered by turning the stem in a counter-clockwise direction.

Diagnosing an air conditioning system can be a challenge. Once technicians grasp the principles of superheat and subcooling, these two system parameters can be very useful in determining if the system is properly charged and working according to the manufacturers' specifications.

This file type includes high resolution graphics and schematics when applicable.

Al Maier is vice president of applications engineering for Emerson Climate Technologies. He can often be found making the rounds on the lecture circuit at major industry educational events. He can be reached at [email protected]