With the phase-out of R-22, production and importation of R-22 refrigerant in the U.S. is limited and will be reduced to zero by the EPA in 2020. The use of R-22 in new equipment was banned in 2010 but servicing of existing equipment with R-22 can continue well after 2020.

Following the ban in new equipment, R-22 was replaced by several refrigerants, including R-410A, R-404A, R-407A, and R-407C, for use in new equipment. For servicing of existing systems, retrofit refrigerant gases were developed to mimic R-22 performance. These gases include R-427A, R-407A, R-407C, and several others.

An equipment owner is left with the question of what to do with aging equipment: keep servicing it with R-22, retrofit the equipment with an alternative refrigerant, or replace the equipment all together with a system running a different refrigerant. This article will explore these options and help in the understanding of choosing retrofit alternatives.

Repair, Retrofit, or Replace?

The basic service question for the owner of R-22 equipment is whether to continue repairing and servicing equipment with R-22, keep the old equipment but retrofit it with a replacement, non-ozone depleting alternative, or to replace the equipment all together with a new system using a new refrigerant. With no requirement to stop using R-22 in existing equipment, the decision is not always straightforward, and depends upon many factors, but some rules of thumb usually apply.

First and foremost is that “if it’s not broken, don’t fix it!” R-22 will generally work best with R-22 equipment, so if the equipment is working well and is relatively leak free then the equipment owner should consider continuing to service it with R-22.

First and foremost is that “if it’s not broken, don’t fix it!” R-22 will generally work best with R-22 equipment, so if the equipment is working well and is relatively leak free then the equipment owner should consider continuing to service it with R-22.

When repairing equipment, if the equipment is still under warranty then it is advised to follow the equipment manufacturers servicing recommendations, which would include servicing with the design refrigerant, R-22. With the ban in new equipment starting in 2010, all R-22 installations are now more than five years old and may no longer be under warranty. However, major components of systems, such as outdoor condensing units of home air-conditioners, can be replaced. These “dry-ship” outdoor units, so called because they are sold without being pre-charged with R-22, will likely come with their own product warranties, as may other system components, and so many R-22 systems in the field may still have significant components under warranty.

If the equipment and major components are no longer under warranty and the system is not working well or needs major repairs then it is time to consider replacing the equipment.

If the equipment and major components are no longer under warranty and the system is not working well or needs major repairs then it is time to consider replacing the equipment. Installing a new system can be quite costly, so the equipment owner will need to weigh the installation cost against the cost of repairing the old system. Many new systems offer significantly higher efficiency than older units do, so replacing the old system with a new, high efficiency option can reduce energy costs to help offset the cost of installation. In addition, rebates and incentives may apply in certain localities as utility companies look to reduce energy consumption.

The third option is to retrofit the old equipment with an R-22 alternative refrigerant, such as R-427A. Retrofitting should be performed properly by a qualified technician, and it involves more than just removing the R-22 refrigerant and replacing it with the alternative. Therefore, a good time to consider retrofitting is when other system repairs will be performed, such as replacing compressors or coils or repairing leaks.

Service contractors should attempt to fix refrigerant leaks during repairs. Since not all attempts to repair leaks will be successful, performing a retrofit and recharging the system with the alternative refrigerant following repairs will help avoid the risk of additional emissions of R-22. This will become increasing important as inventories of R-22 decrease, which could increase the market price of R-22, making retrofitting a more attractive option.

Not all R-22 systems are good candidates for retrofits, and such systems should either continue to be serviced with R-22 or be replaced with new equipment. As will be discussed in more detail later in the article, systems with flooded evaporators or systems that are undersized may not be good candidates for retrofitting.

Retrofit Refrigerants

Once the decision is made to retrofit an R-22 system, the contractor must choose the right refrigerant for the job. There is a long and growing list of refrigerant blends developed to replace R-22 and plenty of advertising claims to sort through.

One marketing concept promulgated in the industry is the notion of “drop-in” refrigerants, the idea being that the only work needed to perform such a retrofit is to remove the R-22 and to recharge the system, or “drop in”, the alternative. In truth, there are no “drop-in” refrigerants for R-22, as no refrigerant can directly replace R-22 in all applications and proper retrofitting procedures should be followed to help ensure the equipment operates correctly following the retrofit. Further, the “drop-in” myth may contribute to inappropriate service practices, such as adding a retrofit blend to a system charged with R-22 to “top off” the equipment. Though there are no true “drop-ins,” some refrigerants are closer in properties and performance to R-22, making retrofitting easier than with other options.

Most of the available R-22 retrofit refrigerants are blends of two or more hydrofluorocarbon (HFC) components. Because no refrigerant could directly replace R-22 in all applications, individual blends were designed to replace R-22 in specific applications or to match certain properties of R-22. Therefore, the contractor must first be sure to choose a retrofit refrigerant that is suitable for the intended application. Even though R-407A and R-407C are refrigerant blends of the same three HFCs, HFC-32, HFC-125, and HFC-134a, the components are used in different proportions, making R-407A better at replacing R-22 in refrigeration while R-407C better at replacing R-22 in air conditioning. On the other hand, R-427A contains four HFC components, HFC-32, HFC-125, HFC-134a and HFC-143a, and was designed to replace R-22 in both refrigeration and air-conditioning. A contractor looking to carry only one refrigerant to retrofit R-22 in either air conditioning or refrigeration systems should then consider an option like R-427A.

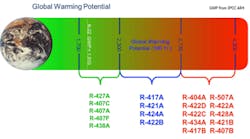

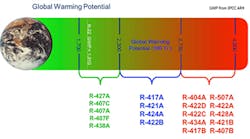

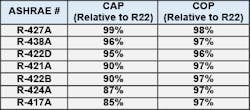

Contractors must remain up to date on which refrigerants the U.S. EPA has approved to retrofit R-22 equipment as part of the SNAP (Significant New Alternatives Policy) Program. A recent action of the EPA for the SNAP Program will effectively ban the use of several high GWP (global warming potential) refrigerant blends, like R-422D, to retrofit R-22 equipment in specific refrigeration applications. Keeping environmental issues in mind, it is preferred to use retrofit blends with lower GWP, such as those shown in green in Figure 2.

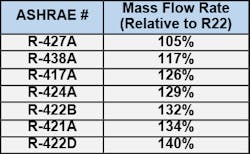

Many retrofits require significantly higher mass flow of refrigerant to generate the same cooling as R-22, as shown in Table 2. This is particularly problematic for systems with non-adjustable expansion devices. If the expansion device cannot deliver high enough flow rates, it effectively serves as a liquid line restriction. Symptoms of this include low operating pressures, low amp draw, and high superheat, but misdiagnosis of these symptoms in the field often results in overcharging of refrigerant. Replacement of expansion devices is thus often required for many R-22 retrofits. The extra work of replacing the expansion device may be avoided if using a retrofit refrigerant with a mass flow rate that is close to that of R-22, such as R-427A.

Oil Issues

R-22 is typically used with mineral oil (MO) or alkyl benzene (AB) oils. However, due to their polarity, HFC refrigerants are generally immiscible with mineral oils or AB. Instead, more polar lubricants such as POE (polyol ester) oil, PVE (polyvinyl ether) oils, or in some applications, like automotive A/C, PAG (polyalkylene glycol) oils, are recommended with HFC refrigerants.

Miscibility of the refrigerant and lubricant helps maintain oil circulation within the system. The oil is only there to lubricate the compressor, but oil that leaves the compressor must be transported through the system and back to the compressor by movement of refrigerant. If the refrigerant and oil are immiscible, oil may collect in various parts of the system, particularly the coldest areas such as in the evaporator. Similarly, in a flooded evaporator a layer of oil may collect on top of the liquid refrigerant pool. If excessive oil collects within the system and insufficient oil is returning to the compressor, the compressor may become starved of lubricant. This will result in excessive wear and premature failure of the compressor. It is therefore critical to use refrigerant-lubricant combinations that provide sufficient oil return to maintain proper lubrication in the compressor. Even if oil return is sufficient to maintain compressor lubrication, oil that accumulates in the heat exchanger will insulate the heat exchange surface and reduce heat transfer, resulting in decreased system capacity and efficiency.

Therefore, when conducting a retrofit of R-22 equipment it is recommended to replace the mineral oil with a suitable POE oil to ensure optimal performance following the retrofit procedure. R-407C, R-407A, and similar refrigerants with very low solubility in mineral oil will likely require complete oil change to POE, flushing the system one or more times to remove remaining mineral oil.

Though all of the HFC retrofit blends are immiscible with mineral oil, some have sufficient solubility with mineral oil as not to require a complete change to POE or to promote satisfactory oil return without an oil change. R-427A, for example, has sufficient solubility in R-22 to not require an oil change for many installations. Some retrofit blends use one or more hydrocarbons (HCs) as components to help improve solubility with mineral oil. The HC dissolves into the mineral oil and acts to reduce its viscosity, thereby thinning the lubricant. Thinning the oil helps move it through the system and improve oil return, but if the oil become too thin it will not provide adequate lubrication for the compressor, leading to excessive wear. Additionally, HCs are highly flammable and so only small amounts can be used while maintaining non-flammable blends. As such, the impact of the HCs in many cases is limited, and the overall blends remain immiscible with mineral oil.

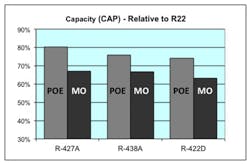

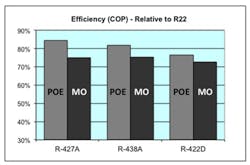

R-22 equipment tests were performed to investigate the impact of lubricant miscibility on the performance of mineral oil tolerant retrofit blends. The tests were conducted on R-22 and three retrofit refrigerants: R-427A, R-438A, and R-422D. R-427A is a blend of four HFCs, R-32, R-125, R-134a, and R-143a, where R-143a provides better mineral oil solubility than the other three HFCs. R-438A and R-422D are two HFC retrofits containing HCs, where R-438A is a blend of three HFCs (R-32, R-125, R-134a) and two HCs (butane, isopentane) and R-422D is a blend of two HFCs (R-125, R-134a) and one HC (isobuane). R-407C and R-407A were not evaluated in these tests due to their very low solubility in mineral oil.

Testing was done with both mineral oil (MO) and POE using same equipment and under the same conditions. Test conditions included box temperatures of 0F, 25F, and 50F and ambient temperatures from 85°F to 105°F. As can be seen in Figures 3 and 4, there was a significant drop in system capacity and efficiency when using the retrofit blends with mineral oil instead of the recommended POE oil. This highlights how using a refrigerant oil that is miscible with the retrofit refrigerants, such as POE, can help ensure optimal system performance.

The data also showed that when using POE under the conditions tested, R-427A exhibited the highest efficiency and capacity of these three retrofits, while R-422D had the lowest. When using mineral oil, R-427A and R-438A showed nearly identical performance, while R-422D exhibited lower capacity and efficiency. Overall, R-427A provided the highest the efficiency and capacity across the widest range of conditions of these three retrofit blends.

Conclusions

As R-22 equipment ages, owners must decide how best to service the installations. In many cases, continuing to service the equipment with R-22 is the best option. If the equipment is not working well and requires major repairs it may be time to replace the equipment with new, more efficient units. Retrofitting the equipment offers a third option, which may be most attractive for equipment requiring minor repairs and if the cost of R-22 makes the retrofit blends more competitive.

When retrofitting, refrigerant selection is critical for ensuring optimal performance and limiting the work required to conduct the retrofit. The key to this is choosing a retrofit with similar properties to R-22, including capacity, mass flow rate, pressures, and efficiency, along with having sufficient solubility with mineral oil to promote oil return. R-427A, having close capacity, performance, and pressures to R-22 across a range of applications, along with not needing to change the oil or expansion device in many installations, offers a solution for easy retrofits of R-22.

With reliable information and proper planning, retrofitting can an effective way to extend the life of R-22 equipment.

Brett Van Horn is a market manager for Arkema. John Maiorana is an aftermarket manager for Arkema.