Correctly measuring and interpreting voltage is essential to every HVAC professional in the field. Installers, maintenance technicians, and service technicians measure voltage daily to gain insight into the electrical functions essential for proper mechanical system equipment operation. Let’s take a look at the procedures for measuring single-phase voltage.

Safety First

Keep this quote in mind each time you measure electrical properties:

“A momentary inattention to energized equipment may easily carry the punishment of death, enforced promptly, without the chance of appeal anywhere on earth.”

Any questions?

While we’re at it, this article assumes you've previously received basic electrical testing and safety training. Follow all electrical safety precautions and use required safety equipment. If you’re not sure what you’re doing, please get adequately trained before testing electrical properties.

Test Instruments and Accessories

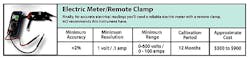

For most HVAC system measurements you'll need a good quality electrical meter with a set of test leads and variety of probes. To measure amp draw, you need a remote amp clamp. Ideally, a true RMS electrical meter is preferred above all others. RMS meters measure true power and trump all measurements made with a standard meter. The initials RMS come from Root Mean Square which is a statistical measurement of the magnitude of a varying quantity and is applied to voltage or current. Now that you know what it means, just say RMS and most HVAC folks will know what you mean. Here are the basic specifications to consider when acquiring a new electrical meter:

Voltage readings are typically taken at the incoming line side of the disconnect switch or at the line terminals feeding power to the unit’s distribution block, contactor, relay or motor starter. These are usually the safest test locations to take voltage readings.

Measure Single Phase Voltage (115 Volt Systems)

Follow these steps in the order presented to assure your success. Remember, if you are not skilled in electrical measure, solicit the help of an experienced technician and practice in the shop before measuring in the field.

- Using the set of test leads, Insert the black probe of the test lead into the meter’s Common (COM) port and the red probe of the test lead into the port marked for voltage and ohms.

- Set your true RMS electrical multi-meter to read “Ohms” or “Continuity." Touch your test leads together to ensure they read resistance or continuity to ensure there are no breaks in the wiring of the test leads.

- Set your true RMS electrical multi-meter to read “AC” voltage or to the V with the wavy line. Select the approximate voltage you intend to test.

- When testing, assure your hands do not come in contact with the live electrical circuit or the metal end of the probe. Touch only the plastic or insulated handles of the probe.

- When you and others are all clear, energize the equipment. Allow the equipment to run for 20 seconds or so and to stabilize.

- Place the black probe on an exposed common wire or to ground, (Often white in air conditioning systems) A probe equipped with a clip works well when doing this.

- Place your red probe on an exposed energized wire. (Often black in air conditioning systems)

- Read and record the voltage displayed on the multi-meter.

- Be careful not to touch any energized surfaces when withdrawing your probes from the test site.

- Compare the measured voltage to the equipment’s required voltage.

Measure Single Phase Voltage (208-230 Volt Systems)

Measurement of 208-230 Volt single phase electrical systems requires an additional step that includes the measurements of two terminals or wires in the system. Record both voltages to accurately express your findings.

- Using the set of test leads, Insert the black probe of the test lead into the meter’s Common (COM) port and the red probe of the test lead into the port marked for voltage and ohms

- Set your true RMS electrical multi-meter to read “Ohms” or “Continuity”. Touch your test leads together to ensure they read resistance or continuity to ensure there are no breaks in the wiring of the test leads

- Set your true RMS electrical multi-meter to read “AC” or to the V with the wavy line. Select the approximate voltage you intend to test

- When testing, assure your hands do not come in contact with the live electrical circuit or the metal end of the probe. Touch only the plastic or insulated handles of the probe

- When you and others are all clear, energize the equipment

- Place black probe to an exposed ground wire or terminal

- Place red probe on an exposed and energized incoming Line 1 voltage terminal or wire

- Read and record voltage displayed on your true RMS multi-meter

- While keeping black probe on the ground location place red probe on Line 2 voltage terminal or wire

- Read and record voltage displayed on your true RMS multi-meter.

Next, Measure the Phase to Phase Voltage

- Place black probe on an exposed and energized incoming Line 1 voltage terminal or wire

- Place red probe on the other exposed and energized incoming Line 2 voltage terminal or wire

- Read and record the phase to phase voltage

- Verify the measured voltage is within the required voltage of the equipment.

Ideally, the voltage should be within the tolerance specified on the equipment. If the voltage decreases upon equipment start up more than 5% this is evidence of excessive voltage drop that needs to be corrected.

Electrical problems are a primary cause of poorly operating HVAC systems. Voltage that is out of range and left uncorrected can prematurely destroy equipment.

Voltage problems have a direct effect on the efficiency and performance of a system. Compressor efficiency drops quickly the farther the voltage varies from the specified voltage of the compressor.

Rob “Doc” Falke serves the industry as president of National Comfort Institute an HVAC based training company and membership organization. If you're an HVAC contractor or technician interested in a free procedure to use in the field on how to measure voltage, contact Doc at [email protected] or call him at 800-633-7058. Go to NCI’s website at nationalcomfortinstitute.com for free information, articles and downloads.