Service Valves

Q: Explain the parts to a service valve.

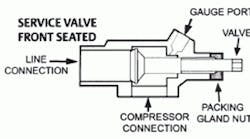

A: The typical service valve is composed of four essential parts: line connection, valve stem, service opening or gauge port, and compressor connection.

Typically, the service valve has a common connection that's always open. When the valve is back-seated (the stem is all the way out), the gauge port is closed and the valve is open, allowing refrigerant to flow through the system. If the valve is front-seated (stem all the way in), the gauge port is open to the compressor connection and the refrigerant line (suction or discharge) connection is closed.

In order to read the pressure while the valve is open, the valve should be back-seated, then turned once or twice to slightly open all three connections: the gauge port, line, and compressor. This allows both the compressor and refrigerant line to be open and vapor pressure to flow through. At the gauge port, you can check system pressure and charge or reclaim refrigerant.

When brazing a service valve: make sure the valve is mid-seated before brazing. The heat from brazing a fully-front-seated or back-seated valve can cause the button of the valve stem (inside the valve) to "weld" to the seating area on the inside of the body of the valve. A technique called "wet ragging" can also help. Soak a rag in cold water and wrap it around the service valve before brazing. Make sure water doesn’t enter the valve.

Copyright 2008 Emerson Climate Technologies, Inc.

All rights reserved. Used by permission.