What might your customers' expectations be of a commercial boiler servicing?

With fuel cost on the rise again, it may be to improve or ensure the boiler's operating efficiency for an upcoming heating season. It may just be part of a service agreement, or could it be to identify situations that could cause no-heat conditions or costly repairs if not addressed.

Whatever the reason for the service, it's important to address both the water side and the fire side of the unit.

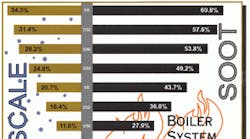

The fire side of the heat exchanger is a good place to start. Just because it burns gas — which burns cleanly — the heat exchanger still needs to be serviced. As little as 1/16-in. of soot or residue buildup can reduce boiler efficiency by up to 27%.

Cleaning Procedures

Be sure to clean every square inch of the heat exchanger. Some boilers may have a number of access openings that may be hidden under the jacket.

Special attention to the type of boiler and the proper cleaning procedure is a must. If you're not familiar with a specific piece of equipment, locate or download the service manuals. For example, for many condensing boilers on the market today, traditional steel brushes will scratch the stainless steel surface of the heat exchanger and potentially shorten the life of the boiler. For these units, clean the heat exchanger with a nylon brush.

Inspect for Corrosion

When the boiler is open, look for signs of corrosion from flue gas condensation, as this may be a sign of system control issues. Check the integrity of flue gas seals between a sectional heat exchanger and all access panels. All seals should be tight, to ensure no flue gas is leaving the boiler except to go up the chimney.

Completely clean the burner of all dust in the housing combustion head and fans. For atmospheric gas boilers, remove the burner tubes so you don't damage them when cleaning the heat exchanger. Then, clean the burner tubes with compressed air before reinstalling them. This complete cleaning will allow for better combustion performance. A measure of cheap insurance is to annually replace the gas burner ignition electrodes and flame rods.

For oil burners, completely clean the fuel system, including the filters and nozzles. Once you restart the burner, a combustion analyzer is a must to recalibrate combustion.

Properly Tune Combustion

With condensing boilers, the dew point (the point in which the flue gas begins to condense) is affected by the CO2 /O2 or lambda of the combustion. To ensure the best efficiency from a condensing boiler, make sure to accurately tune the combustion.

Inspect operating and safety control limits for proper operation. In steam systems, test the low water cutoff. For water systems, activate the test button on the low water probe to ensure proper operation. All fixed and operating limit controls need to be checked to ensure that they safely shut down the burners.

Efficiency Settings

Some hot water boiler systems may have outdoor reset controls. This control changes the supply water temperature based on the outdoor temperature: i.e., the colder the outdoor temperature, the higher the boiler water temperature. This control may be adjusted to a lower setting in an attempt to maximize system efficiency. However, it's common to set these controls based on an assumption of what the building would need for water temperature on the coldest day of the year. Without experimenting with different curves, you may never find the one that ensures maximum efficiency. Use caution with non-condensing boilers to ensure that you don't operate such boilers below their minimum return water requirements.

Most boilers have no access to the water side, however this is a place where heat transfer efficiency can be reduced due to scaling or sludge. System water leaks need to be addressed to reduce makeup water to hot water boilers. Check water treatment systems for steam and hot water boilers for proper operation. If the system fill liquid is glycol antifreeze, check the pH level to ensure that it has not become acidic. In fact, it's a good practice to have the boiler water regularly tested for proper pH levels. Both the acidic or alkaline system liquid can have adverse effects on the heat exchanger.

Finishing Touches

Finish the job with a quick cleaning of the jacket and burner. This will increase the owner's perception of what he or she has paid for. Think about the auto dealership that washes and vacuums your car after a simple oil change. You didn't look for the new oil filter or check the dipstick, but you did notice that the car was nice and clean, and you felt better driving it.

Twenty-first century boilers are remarkably efficient, dependable pieces of equipment. With the proper attention from you, your building owner customers will get the most from their boilers for years to come.

Stephen David is the commercial sales manager for Viessmann Manufacturing Co. (U.S.), Warwick, RI. He can be reached at 401/732-0667 or by e-mail at [email protected].