Building information modeling (BIM), integrated project delivery (IPD), Total Station surveying, and project team "co-locating" have become firmly entrenched as established construction methods. There’s just no way enterprising contractors can forego the benefits these processes provide to construction preplanning and project fulfillment.

However, these progressive methods aren't without their own unique challenges. During the most recent Mechanical Contractors Association of America (MCAA) annual conference, leading proponents of these methods offered their advice in a session titled, “What’s Next in BIM and IPD?”

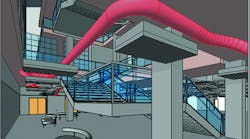

uses digital 3D or 4D representations of a building’s interior and exterior space, objects, and characteristics. With BIM, architects, surveyors, contractors, building services personnel and owner/operators have a virtual information model to work with for the life of the structure.

Integrated Project Delivery is a construction delivery system that aligns the needs and objectives of all project teams, such as architects, general contractors, and sub-contractors.

A Total Station is an electronic method of surveying, planning, and locating hangers and other crucial project design elements.

With co-locating, the MEP contractor’s project management and/or BIM personnel are required to work literally in the same room on the jobsite.

BIM’s Beginnings

In describing the early history of Building Information Modeling, Pete MacKenzie — an MCAA National Education Initiative (NEI) instructor, who also oversaw the development of the BIM department of Mechanical, Inc., Chicago, IL — explained to the audience of mechanical contractors that the earliest users of BIM were mechanical and structural contractors who had experience with prefabrication, and wanted to enhance their prefabrication skills further by learning to wield BIM’s digital magic. And, while they were successful, MacKenzie said general contractors eager to be all things to all customers took notice.

“Mechanical and structural contractors’ success with BIM created a rush by general contractors, who took good notes, and rushed to claim that they had the same capabilities,” MacKenzie said. “Many stepped in to grab the reins without any real-world training or trade-skilled personnel, and found themselves dependent on capable trade contractors to make things happen. As a result, the GCs and CMs are stepping into this new role with varied levels of management and success. The consequence of this has varied in different regions of the U.S.”

MacKenzie explained that on the West Coast of the US, where many sophisticated mechanical contractors have been leading the BIM process for several years, owners are beginning to realize that the process is actually controlled by the subcontractor, and are demanding that the GCs take control of that process.

BIM works best when general contractors

and construction managers require the

participation of all trades in the BIM process,

with common document control,

and common directions.

He said the trend is somewhat different in the Midwest. There, general contractors are assuming the BIM role in some cases, while others that have encountered problems are giving it back to the mechanical contractors. Whatever the situation may be, MacKenzie said it can’t be denied that BIM has created a paradigm shift in how mechanical contractors conduct business today versus five or six years ago.

MacKenzie said BIM works best when general contractors and construction managers require the participation of all trades in the BIM process, with common document control, and common directions. “This gets everyone on the same page, and the process runs more smoothly,” he said. “And, GCs who are so inclined are in a good position contractually to provide the leadership that’s needed to make these things a reality.”

He added that general contractors in control of the BIM process might also provide better coordination of design teams, because of the contractual structure of most projects and their influence over design team and owner. “When problems arise, they can compel the design team to come to the table to resolve those problems,” MacKenzie said.

If the GC or CM permits the mechanical plumbing contractor to lead the BIM process, the mechanical contractor will have a major influence over those factors that will allow him to execute more efficiently and productively, and develop management expertise in the firm’s BIM personnel. “They can become much stronger and better at what they do, and you can market those skills and abilities,” he said.

The Danger of Inexperience

Often, however, a GC will assign a lead role to a young, computer savvy but inexperienced college graduate. As a result, MacKenzie said, they struggle to make up for their inexperience with bravado and posturing.

“Combine that with a lack of understanding of what it takes to coordinate an area, and it often leads to unreasonable schedules and expectations, schedules that may have no basis in established history or correlation to the actual construction schedule,” MacKenzie said. Additionally, he said a misunderstanding of the time required to coordinate an area could lead to too early or too late project startups.

Conversely, he continued, some younger leaders may lack confidence due to inexperience, which may lead to inadequate authority over the process, basically resulting in the “rudderless ship” syndrome.

Another challenge will occur when the GC will attempt to complete an inadequate design by passing it on to the coordination team, as coordination tasks.

“That’s a scenario we call “coordination morphing into redesign,” MacKenzie said. “It leads to a lack of concern for financial impacts, and the use of ambiguous contract language in an attempt to deny just compensation resulting in changes caused by inadequate design.”

There are many BIM requirements you might see on customers’ lists, but focus first on how it will benefit your business directly, and expand that to how it helps the entire project when every trade is using this technology to its fullest.

- Mechanical contractors must ensure that their teams understand all expectations. At the project kickoff meeting, explain to the general contractor and project team what you expect to get out of the process.

- Demand a BIM execution plan that defines clear roles, responsibilities, expectations, and consequences. If the GC provides a plan, review it thoroughly. If they don’t, create your own execution plan and propose it to the team.

- Keep your project management team involved. “BIM is a function of project management. If it falters, your project will falter. Make sure the team is involved from beginning to end,” MacKenzie urged.

- Monitor the process. Hold weekly status meetings with your own team. Discuss current status. Look ahead. Above all, don’t let yourself be blindsided.

- Sound the alarm early and loudly if and when the process goes awry. “These are problems that never get better on their own, they only get worse,” MacKenzie said. “So you need to identify and define those specific problems, develop plans to mitigate them and put them into effect.”

- If the opportunity arises and you're qualified to take the lead, do so. You'll be a big factor in the project’s success.

Michael Cannistraro, P.E., LEED AP, is vice president of J.C. Cannistraro LLC, Boston, MA. He works in every stage of the building process from design to coordination, prefabrication, and installation.

He told the audience at MCAA that BIM enables more prefabrication. “We’ve seen increased accuracy in shop drawings now that everyone is using 3D,” he said. “The detail has allowed us to be more confident in prefabrication. The benefits of prefabrication include efficiency, quality, and the safety of moving field hours into a controlled environment in a prefab shop. “Imagine if every trade were to do that. Imagine how fewer injuries there would be on-site,” he said.

Cannistraro said a contractor may receive many BIM requirements from customers, but they should focus first on how it will benefit their business directly, and then, how it helps the entire project when every trade is taking full advantage of this technology.

Ups and Downs of Co-locating the Team

MacKenzie said contractors have varied opinions of co-locating. “GCs like co-location, because they can see us working on the project, and think they have more control in-person,” he said. “Some on-site project managers also like co-location because it gives them daily, in-person contact with the coordination team.”

MacKenzie agreed that co-locating has some distinct advantages. All stakeholders can focus solely on the project. Co-locating provides an environment for collaboration, provided that the right stakeholders are involved and join into the process at the most opportune time. Co-locating also provides for faster communication and resolution of problems and dissemination of information. Technically, with a properly configured network and a model structure, the 3D model can be updated continuously.

Finally, detailers are available for on-site personnel and vice-versa. “For our company, successful integration of BIM technology into the field’s workflow is an absolute necessity. Having detailers and on-site personnel available can go a long way to making that happen,” MacKenzie said.

Among its disadvantages, co-locating can reduce the MEP’s control of his staff. According to MacKenzie, the GCs might attempt to circumvent your established chain of command and go directly to the detailers with tasks, directions, or critiques. And, co-locating detailers are often isolated. Detailers are removed from resources and mentoring they get from working with the rest of the CAD/BIM staff, and detailers aren’t available to work on other projects or fill non-productive time. “Therefore it takes away the contractors’ ability to best juggle task and projects in order to meet all of your project commitments,” MacKenzie said.

With co-locating, project cost is determined more by time than by the scope of project. MacKenzie said the contractor’s estimate must be based on the co-location duration and desired staff, rather than the multipliers that are usually used for project coordination.

Finally, MacKenzie said, document control could be lost, and space, infrastructure and IT requirements can often be inadequate.

Let the GC know in writing what you will and

won’t be providing for the co-location.

“A common co-location problem we’ve encountered is that you get an inadequate allotment of office space. When jammed into a trailer like sardines in a can, detailers are less productive, distracted by excessive noise and a lack of privacy. In those conditions, they can be more prone to error," he said.

MacKenzie offered five suggestions for workable co-location arrangements:

1. Review and monitor your co-located efforts. Demand that a clear set of requirements for co-location, review them and formulate a plan for fulfilling them while satisfying your own needs. Be sure to monitor your state of affairs as the project progresses.

2. Set limits to your participation. Let the GC know in writing what you will and won’t be providing for the co-location. Feel out the GC, and offer alternatives whenever possible. For example: one co-located detailer only, with office support staff as needed; extensive use of online conferencing for regular meetings, daily updates, or as needed; cloud model management to provide automatic and continuous model updates to all participants, onsite and offsite.

3. Ensure that the design team remains engaged. Push for regular onsite participation from the design team. Use online conferencing to address issues as they arise.

4. Be certain your staff follows your expectations and protocols. Make it clear who they work for and who they answer to.

5. Demand reasonable working conditions. Your detailers should have the same working conditions that allow for the same level of productivity that they achieve in the office.

BIM ‘Total Stations’

Over the last several years, the increase in the office computer technology directly relates to how the building project comes together, and how it's prefabricated, said Michael Cannistraro. “Total Station” electromechanical survey equipment is one of those new technologies.

Total Station is surveying software and equipment that's used to identify locations of points in the field, of where hangers and sleeves go based on triangulation and/or GPS.It allows a worker to layout hangers and various other “intertion points” directly from the computer model, without using a tape measure. He said this results in higher accuracy, improved efficiency, and faster schedules.

Cannistraro said there are many nuances to using Total Station

equipment, so the right people must be well-trained

in order to use it effectively.

Potential Challenges with Implementing Total Station Technologies

Total Station equipment costs some big bucks, about $25,000. Additionally, scheduling and sharing the machines can be a challenge, and the equipment must be protected against theft.

“We have a couple of them at my company and they’re in constant use,” he said. “There’s always a demand for them on every project. So you have to think about things such as transportation and security of that equipment.”

Employee resistance can exist. For some in the field who aren’t computer savvy, and have done things in a particular way for 25 years, Total Stations can pose a challenge. However, Cannistraro said that by explaining to employees the benefits of Total Stations, they'll understand how it will make their lives easier, and become its biggest supporters.

Third, there's required maintenance and downtime associate with each of these tools, because they occasionally need to be updated with firmware and software upgrades. Each of those updates requires that the equipment be out of use for up to two weeks.

Total Station equipment requires training. Cannistraro said there are many nuances to using Total Station equipment, so the right people must be well-trained in order to use it effectively. When you’re starting out, choose a smaller project that would make sense, some "lower hanging fruit."

“For our first Total Station project we borrowed a unit from a sheet metal contractor we do business with,” he said. “We tried it, and came to understand how it could benefit our business. We also had a specialist who went from jobsite to jobsite doing this on every job.”

Whether you’re using cloud computing or other information storage, keep your models up to date, to stay in step with software iterations and revisions. “Make sure everyone’s working off the latest and greatest information, and that the equipment and hardware is secure and suitable for field use,” he said.

“Make sure you’re using the same equipment and procedures across your different projects. It’s very important so that you can implement it strategically.”

Prefabrication

BIM has taken the mechanical contracting industry towards more of a “prefabrication culture" that improves project efficiency. Cannistraro said contractors in the Boston area have shown very little resistance to prefabrication, mostly because workers enjoy going to the prefab shop, out of harm’s way and protected from the elements.

The cost of setting up prefab facilities can be challenging. There’s a lot of equipment and real estate needed to do this, so you need to have good cash flow and work flow, Cannistraro said.

The MEP contractor must recognize the transportation requirements involved in getting assemblies to the jobsite. “How do you divide those sections up, and model how they fit on your trucks? What does the access to the jobsite look like?

His suggestions:

- Visit other prefab operations. MCAA does a prefabrication conference every year in March. Look into that for 2014. It sells out very quickly. (Visit our photo gallery of an MCA pre-fab tour, at MCAA Pre-fab 2013.)

- Find the right person to lead the effort. This has to be someone who understands the technology, its benefits, and how it all “comes together.”

- Seek continuous improvement. That’s incredibly important. Once you’ve figured out the prefab there’s always room to make it a little bit better.

BIM and Integrated Project Delivery

Steve Shirley, president/CEO of University Mechanical, San Diego, CA and a chairman of the MCAA BIM and education committees, told conference attendees that BIM has greatly accelerated the use of integrated project delivery (IPD).

“Basically, you become part of an IPD team, under contract, where you know your direct costs will be covered. But, you may or may not make a profit, which is dependent on the success or failure of the entire team in reaching its goals.

The major impetus to IPD is that it help building owners make money. “If the owners of these building didn’t make

The cost of setting up prefab facilities can be challenging.

There’s a lot of equipment and real estate needed

to do this, so you need to have good cash

flow and work flow.

money, we wouldn’t see IPD,” Shirley said. “The owners of these buildings drive this bus, no matter what mechanical contractors might think. Basically, you become part of an IPD team, under contract, where you know your direct costs will be covered. But, you may or may not make a profit, which is dependent on the success or failure of the entire team in reaching its goals."

Shirley said IPD enables the MEP contractor to become engaged in the process early on.

"I've never seen and IPD contract in which the mechanical contractor is brought in after the design is completed," he said. "They want you there, because you bring value, by virtue of your knowledge of the problems that repeat themselves when it's left strictly to the architects and design teams."

IPD can create a true team atmosphere, and it will eliminate some battles because it’s the owner’s money, and all want to spend it wisely. It also educates and enlightens all team members. “Knowing the ductwork’s relationship with the drywall is beneficial. Someone should step in with common sense,” he said.

Shirley said it’s important that the mechanical contractors help set IPD goals. “Don’t let someone else go through some competitive bid process, and then tell you what the goals will be.”

Reimbursable costs involved with IPD must be defined. “Make sure you know exactly what you’re getting paid for, such as pickup trucks and vehicle mileage. Owners can fail to consider all sorts of items. Make sure you know which costs are covered.”

Understand how your scope will change with changes in schedules. “Many owners will assume they don’t have to worry about change orders. It can get hairy if you don’t understand how these changes might affect the contract. Resources can be consumed with reduced or no profit if a team member fails.”

For successful IPD implementation, Shirley suggested that contractors:

1. Join teams with clients and team members that you like and trust. It will make successive jobs far more efficient.

2. Choose team members carefully. “There are people in our companies that can’t work in the IPD environment because they’re not collaborators,” he said.

3. Include certain “overhead” burdens as “reimbursable costs.”

4. Understand how and when profits will be recognized and distributed. Your cash flow suffers if you can’t do this.

5. Ensure the team has multiple layers of authority.

For information on MCAA NEI classes in BIM and other courses related to project management, visit http://www.mcaa.org/nei/

Terry McIver is executive editor of ContractingBusiness.com, a Penton publication. Follow Terry on Twitter @TerryMcIver