A school superintendent speaking at the ASHRAE 2015 Annual Conference, June 21-July 1, attributes improved school attendance at a new school to improved indoor air quality in the form of improved relative humidity.

"The first year our new George Rogers Clark (GRC) High School opened, we achieved the highest student attendance figures in our school district's history and I attribute that mostly to its (unprecedented) indoor air quality (IAQ)," said Paul Christy, superintendent, Clark County Public Schools, Winchester, Ky.

Christy presented his school district's newest green facility design, the $60-million GRC, to a 70 engineers attending the American Society of Heating Refrigerating and Air-Conditioning Engineers' (ASHRAE) 2015 Annual Conference in Atlanta. Chaired by Thomas Rice, director of sales, SEMCO LLC, a Columbia, Mo.-based manufacturer of chilled beams and energy recovery equipment, the educational seminar, "Energy Performance of Active Chilled Beam Installations," was one of dozens of workshops, seminars, forums and technical paper sessions presented by more than 300 speakers during the five-day conference. ASHRAE Distinguished Lecturer, Stephen Hamstra, P.E., president, Greensleeves Energy Solutions, Findlay, Ohio, also teamed with Rice and Christy to present his ASHRAE Technology Award-winning Davis Building HVAC design at the University of Findlay.

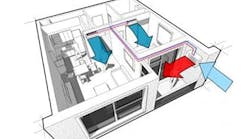

Christy, who was the district's operations director (maintenance and construction projects) during the 300,000-square-foot, two year-old school's design phase, was instrumental in choosing an HVAC system featuring an 80-well geothermal field that supplies active chilled beams and several dual-desiccant wheel dedicated outdoor air systems (DOAS) that maintain 50-percent relative humidity (RH) . "I didn't know in the beginning what type of system we would eventually have, but I did know I wanted high IAQ and low energy costs," said Christy, whose previous position afforded him diverse HVAC concept experiences before assuming his current superintendent role.

Originally, Christy had considered a geothermal system supplying 350 water source heat pumps (WSHP), however his maintenance director balked at the labor and cost of maintaining that much equipment and the significant mechanical room space it would require.

Christy instead chose the second option of 572 low-maintenance chilled beams for classroom cooling and heating, although large rooms, such as the cafeteria, gym and auditorium still rely on several WSHPs. Designed by consulting engineer, Charles H. Wade, P.E., vice president, KTA Engineers, Lexington, Ky., each classroom has four chilled beams operating at 450-cfm or 15-cfm/person.

The upfront capital cost of the current design with chilled beams was $19.50 per square-foot, which was slightly less than the geothermal/WSHP option and other more conventional HVAC approaches. Besides upfront capital cost and space savings, using chilled beams versus WSHPs also reduced construction costs because they required less geothermal wells, less geothermal system piping and greatly reduced ductwork.

The original design's outdoor air dehumidification specified air-cooled rooftop units with a single energy wheel. Instead, Christy opted for a dual-wheel DOAS to handle outdoor air as well as indoor air dehumidification. It also cools ventilation air to a 43F dew point, which eliminates the potential of chilled beam condensation. "The DOAS' recirculation mode during minimum night and weekend ventilation periods has been huge for our energy savings goals," Christy said. "Our maintenance staff has learned this system's sophisticated controls and is now utilizing its greatest efficiency potential."

Soon after opening, Christy quickly discovered he had to train teachers to keep windows shut and trust that the DOAS's constant volume and 50-percent RH would enable superior air comfort at a higher 75F thermostat set point versus the old high school's ingrained culture of 68F classroom set points. "All of the district's other (more conventional) buildings receive occasional 'too warm' complaints, but we've had minimal complaints even at the higher 75F recommendation at GRC," Christy said.

While teacher complaints have been few, praise for chilled beam technology's reduced operational noise versus conventional ventilation systems have been plentiful, according to Christy. "Many teachers can't believe the system is operating because they can't hear anything," Christy said.

Maintenance for the chilled beams is a manufacturer-recommended vacuuming of the coils every five years. "My maintenance department loves this system, because there aren't 350 WSHP fan filters to change periodically and no drain pans to deal with," said Christy.

Even though it's 100,000-square feet larger than its predecessor and operates 35-percent more energy intensive technology, such as computer labs, GRC's energy costs are $100,000 lower annually than the old high school. The 1,800-student school is operating at 31-kBtu/s.f., which is 66-percent less than the national high school average of 96-kBtu/s.f. GRC's kBtu/s.f. surpasses all other Kentucky high schools and lowered Christy's school district buildings' average to 62 from 75-kBtu/s.f. "High efficiency lighting and a better building envelope (than the old school) contribute to this facility's overall utility savings, but the HVAC is a large part of it," Christy added.

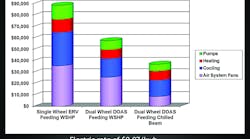

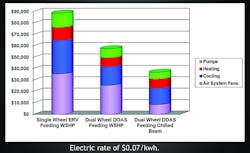

While pump, heating and cooling electric costs are similar to the other HVAC system options, fan energy is more than 50-percent less with chilled beams versus WSHPs, according to a preliminary energy modeling Christy commissioned during the design phase. "Today we're saving slightly more fan energy than what the preliminary energy modeling predicted," Christy said.

Christy provided tips for the seminar's attending engineers considering future chilled beam/DOAS designs. Chilled beam condensation (raining in the classroom) is not a consideration if humidity control is planned properly with a DOAS. "We have not had once instance of condensation from the chilled beams in our two years of operation," Christy said.

Another important point for consideration is air comfort. Two chilled beams in a typical size classroom may not be as adequate as the four chilled beams specified per classroom at GRC.

Kentucky taxpayers appear to be getting their money's worth out of the new high school. Besides the $100,000 in annual energy savings, which Christy said will be applied to three more teachers to reduce teacher/student ratios, the increased attendance figures generated $50,000 in federal incentive funds. U.S. News and Report lists GRC as the 17th best high school in Kentucky and 1,726th on a list of more than 22,000 schools nationally. The school's IAQ and its affect on attendance and productivity figured heavily in the high ranking, according to Christy.

Christy now hopes to duplicate GRC's HVAC success at the Robert D. Campbell Junior High with a chilled beam/DOAS design, but without geothermal because it's a retrofit. Christy summed up the seminar with the comment, "students have to be present (attendance) and comfortable in order for true learning to take place."