REFRIGERANT SERVICE TODAY

Refrigerant Transition Facts

In our continuing mission to keep contractors informed related to the ongoing HVACR refrigerant transition, here are the most important requirements, as shared by Jay Crowe, head coach and trainer, and Dave Consulo, lead head coach and trainer for Business Development Resources (BDR), during the BDR SPARK2024 Conference, Jan. 9-11, Savannah, Georgia.

The 2020 AIM Act directs the EPA (Environmental Protection Agency) to establish a phase down plan that relects the Kigali amendment. The EPA determined the Global Warming Potential (GWP) of 700 for comfort cooling and ice rinks.

CARB in California has the GWP limit set at 750.

The refrigerants that are most preferred as total replacements for R-410A are R-454B and R-32. Both are classified as A2L -- or mildly flammable -- refrigerants.

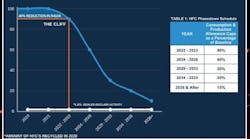

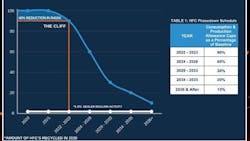

Refrigerant formulators have started to reduce production of HFC refrigerants at a faster rate than expected (by 10% in 2023 and a 40% reduction in 2024). The EPA final rule will phase down the U.S. production and consumption of HFCs by 85% over the next 15 years, as mandated by the American Innovation and Manufacturing (AIM) Act that was enacted in December 2020.

Manufacturers are moving away from A1L refrigerants and moving to A2L/mildly flammable refrigerants.

HVACR contractors will be required to observe new requirements related to tools, vehicles, storage areas, cylinder use, code and fire official permits and possibly licensing.

Tool Changes

- New, "no spark' drills

- Scales and vacuum pumps will not be affected

- A2L-specific leak detectors will be needed

- Due to the cylinder changes, technicians may need to obtain new hoses. The new cylinders will thread to the left.

Storage

The storage area changes for A2L refrigerants are as follows:

- "Non-Sprinklered" areas are allowed for storage.

- The maximum amount of A2L refrigerant that can be stored is 20,000 lbs.

- Shelves or racks for storing A2L refrigerant must be made of steel.

- There must be a 20-ft. separation between A2L products and other flammable liquids.

- The maximum height of the product on the shelves or racks is 6-ft. unless the area has sprinklers.

- A Code/Fire official permit is required for storage.

- A Class B fire extinguisher must be present in the storage area.

- Signage indicating the presence of A2L refrigerants is required.

Vehicle Modifications Required

- R-454B refrigerant has a maximum ambient temperature of 125 degrees

- The new freon cylinder has a pressure relief valve instead of the old rupture disc. Ths greatly increases the potential of product loss.

- Cylinders must be secured in the service vehicle

- HAZMAT protocols will be required if transporting more than 26 pounds of A2L refrigerant. This includes Class B fire extinguishers and appropriate warning signage.

Cylinder Changes

- The new cylinders will be grey with a red strip along the top to warn of flammable substance.

- The cylinders will have a pressure relief valve

- All cylinders containing A2L refrigerant will require two labels: "Flammable" and "Compressed Gas"

- The new A2L cylinder has a pressure relief valve instead of the old rupture disc. This greatly increases the potential of product loss.

Licensing

Contractors will want to review their EPA Section 608 licensing to be sure they are up to date with curent certification and licensing requirements.

Training & Communication

Educate and Train. Educate all team members on the changes and challenges that lie ahead.

Develop a script for team members to use when discussing refrigerants with customers: inform, educate and offer.

- Train technicians and Installers: Ensure that technicians and installers have a thorough understanding of why replacing may be a better option than repair.

- Updated repair vs replace policy.

- Customer messaging: Educate customers on the changes coming and their options.

- Make upgrading equipment affordable for customers by offering financing options. This can help spread the cost over time and provide monthly cash flow for households or businesses.

To regulate the ambient temperature of the A2L refrigerant will require a specialized reclaiming truck, a specialized reclaiming trailer, roof vents in the van and a cooling mechanism.

Meet with your distributor territory managers to learn how they plan to navigate the many changes. Ask them when they are receiving A2L-specific equipment and when they will begin stocking the new tools, including hoses and leak detectors.

CORRECTIONS

A previous version of this article had listed the GWP limit for comfort cooling as 750. The correct number is 700.

The previous version of this artlce referred to the "A1L family" of refrigerants. There is no "family" of refrigerants.

The previous version of this artlce stated that the supply of R-410 refrigerant would be reduced to 15% of normal by 2036. In fact, the phase down is not refrigerant-specific. It is a CO2 equivalent that refrigerant formulators and importers need to use as a guide for determining which refrigerants they will sell into the market.

Contracting Business regrets any inconvenience caused by the errors.