Provide Effective Safety Training

By David F. Coble

Content – What Do They Need to Know?

There are two basic reasons to provide safety training: (1) To teach someone to perform a task safely (training) and/ or (2) To increase safety awareness (education). Here are some important elements to consider when preparing content:

Level of knowledge and skill of the participants: Determine the educational and experience background of employees. What is their length of service in the industry and the job? Would this be for new employees or retraining for current employees?

Time allotted: The time available is critical. Should the training be spread out over several days or weeks, or must it be provided in a short period? Will management let workers go for a sufficient time?

Training facility and equipment available: Will the training be away from the distractions of the job or at the job site? Classroom style seating encourages formality, while U-shaped seating encourages discussion and participation. Will the training be classroom or tool box or can we get the trainees out into the field for hands-on experience? Is there an opportunity to use a PowerPoint or video, or will the facilities not support the use of A/V equipment?

Amount of participation needed by the attendees: Is the goal to pump information into the attendees or do they need to learn a new skill? Should the attendees participate? How about some role-play, exercises, demonstrations, and even the participants handling some of the training duties?

Planning the Training

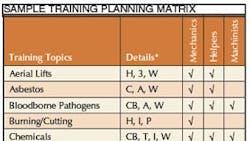

The best practice to plan the training is to conduct a needs assessment and prepare a matrix of the training needed. Use OSHA and industry standards to determine what training is required based on what activities your employees perform. Also, review injury and illness records, and close calls to see where hazards may exist. Watch and talk with the employees to see what they do, what tools and equipment they use, and where weaknesses may be. Next, prepare a matrix of training needed such as the one shown on this page.

The Top 10 Most Important Training Topics for Sheet Metal Workers

Based on a study of available literature, a discussion with two representatives of the Sheet Metal and Air Conditioning National Association, a journeyman sheet metal worker, and my own 34 years of safety experience as a North Carolina OSHA inspector and as a consultant, I believe the top ten most important training topics should be:

- Use and inspection of portable ladders

- Use of fall arrest devices — harnesses and lanyards

- Use of scaffolds and aerial lifts

- Use of manual handtools and powered tools

- Hearing conservation and respirator use for galvanized metals and chromium

- Welding, burning, and cutting safety

- Electrical safety work practices

- Machine safety such as shears, roll formers, press and duct brakes, and grinders

- Proper ergonomics, hand and body positioning, and lifting techniques

- Fire protection, such as using a fire extinguisher, flammable liquid handling and doing hot work

Delivery — Types of Training and Techniques Available

There are two basic types of training: instructor-lead and no instructor. Instructor-lead includes classroom, toolbox, and on-the-job training. No instructor includes computerbased and self-paced programmed training. Consider the positives and drawbacks, as shown in the table below, when planning training.

Studies indicate that adults learn chiefly by participating. There is a lot of truth to the Confucius quote, “I hear and I forget. I do and I understand.” The most effective participatory activities include games, hands-on practice, hazard hunts and quizzes. Safety games may include Safety Bingo (use a Bingo card of terms used during the training, and have the attendees mark the card when they hear a term used), and trivia quizzes.

For example, when I teach about hand tool safety, I pass around damaged and misused tools and explain how someone was injured using that or a similarly damaged tool. When I teach about grinder safety, I bring a grinding stone, demonstrate the ring test, and pass the stone around asking each attendee to perform the ring test. Hazard hunts can be done through pictures, video, or a walkthrough of the job site. Ask the attendees to look for issues that could potentially hurt someone, or to look for something that is different from what they would expect, based on their education, training and life experiences.

Effectiveness – Was The Training Understood? Now it’s time to see if the training paid off and the planning was effective. There are several easy and effective evaluation techniques that can be used together or individually.

Session critique: Pass out a short evaluation sheet to ask the attendees what they learned and how the session can be improved. Key questions should include: Did you learn anything new? Were the learning techniques interesting and effective? What should have been covered but wasn’t, or should have been covered better? What part of the training was of most value to you?

Testing: A short, five- to eight-question test at the end of the training can be given in writing or orally. The test can be taken individually, or reviewed as group.

Demonstration or observation: Ask each attendee to demonstrate what was learned if the subject is appropriate for that technique. This can be performed at the training session or at the job or task location.

Supervisory Evaluation: Good practice is for the supervisor to evaluate the employee’s new skills or knowledge by observation about one week after the training. This can also include a short interview by a supervisor to ask pertinent questions of the employee to see what was learned.

Conclusion

How badly could one of your workers get hurt? They could die, couldn’t they? I don’t want you to dwell on that, but I don’t want you to forget it, either.

David F. Coble, MS, CSP, is president of Coble, Taylor & Jones (CTJ) Safety Associates, Cary, NC. He can be reached at 919/466-7506 or [email protected]. For more information about CTJ Safety Associates, visit www.ctjsafety.com.

This article is based on a presentation, Effective Safety Training Techniques, that Coble prepared for the 2007 Annual Convention of the Sheet Metal & Air Conditioning Contractors’ National Association (SMACNA). For more information about SMACNA or the Annual Conference, visit www.smacna.org.