Underfloor air-distribution (UFAD) systems have been used for comfort-conditioning office spaces in United States office buildings since the early 1990s. Systems were initially employed in high-tech office spaces where in addition to occupant comfort, ease of office space re-configuration (churn) was a priority for building owners. UFAD systems deliver air to occupied spaces through floor-mounted outlets supplied by conditioned air from a pressurized plenum beneath the suspended floor.

A properly designed UFAD system takes advantage of thermal stratification. The key is to have a diffuser that rapidly mixes air without penetrating the stratification layer at the ceiling.

A properly designed UFAD system takes advantage of thermal stratification. The key is to have a diffuser that rapidly mixes air without penetrating the stratification layer at the ceiling. The pressurized plenum -- the area between the slab and raised floor -- is essentially a large duct maintained at a constant pressure differential to the room above; typically, between .05 and .10 in. pressure (w.g.). This pressure is maintained through the supply of conditioned air from a number of supply-duct terminations. The spacing and location of these ducts are dependent on the air supply requirement and the plenum depth which typically ranges from 12-in. to 24-in. If zone control is desired from the underfloor plenum, it can be partitioned into separate zones. The return air for a UFAD system should be located at the ceiling or high sidewall. This allows heat from the ceiling light to be returned before it is able to mix with the occupied zone. There is also a small amount of “free cooling” due to the natural buoyancy of hot air.

VISIT TITUS AT THE AHR EXPO, in booth C317

Some of the concerns typically associated with these systems are humidity, dirt, spillage, and leakage. A potential problem with the higher supply temperatures used in access floor air-distribution systems is the higher potential moisture content of the 60-65F supply air most commonly used in these systems. The supply system must reduce relative humidity to less than 65F. Potential solutions are either the reheat or blending of air to achieve a 65F supply, 55F dew-point condition. System designs utilizing condenser water reheat, run-around coils (face, bypass), and other strategies can be employed to solve these potential design problems. Other options include the use of desiccant dehumidification. Although underfloor air-distribution systems are not recommended for areas with a high potential for spills such as bathrooms, cafeterias and laboratories, small spills are not a problem for most applications.

Typical swirl diffusers used within the interior have a dirt/dust receptacle to catch spills and dirt from normal daily use. The dirt/dust receptacle has a basin that will hold anywhere from 4-6 fl. oz. of liquid. The dirt/dust receptacle can easily be removed and cleaned to keep dirt out of the underfloor plenum. Leakage is typically due to poor sealing or the construction quality at window/wall locations, stair landings, electrical outlets, etc. These areas have to sealed and framed so the supply air does not travel up the wall toward the return air. There can also be leakage between the floor panels which can be reduced by staggering the carpet tiles over the floor tiles. The key is to limit the number of penetrations into the raised floor which will reduce the number of areas that need to be sealed.

Since typical floor plenum pressure is less than .10 in w.g. (25 Pa), energy-efficient low-pressure fans can be used. In place of complicated and expensive duct systems required to supply air to each individual air outlet in a ceiling system, UFAD systems deliver air to building zones using a limited amount of ductwork to create an air highway.

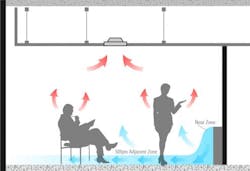

Where a traditional overhead mixed system provides comfort-conditioned air from the floor to the ceiling, partially mixed systems like UFAD save energy by providing comfort-conditioning in the lower occupied spatial zone. They allow the upper zone to stratify.

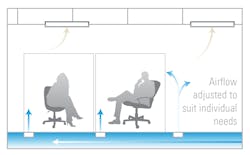

In the core of the building where loads are relatively constant, round (swirl) or rectangular outlets are located in the floor near the occupants. Outlets typically deliver 80-100 cfm (38-48 l/s) of conditioned air to the space. Some of the units have volume control adjustability by the occupants to increase individual comfort levels. The round swirl diffusers are typically available with an occupant adjustable flow regulator that can be either manually adjustable or by the use of a room sensor that is connected to an actuator mounted directly on the diffuser. Installation of swirl units has been made easy by replacing the mounting ring which was previously attached to the unit beneath the floor tile with spring clips to provide a press fit directly into the floor tile.

Some of the biggest challenges for underfloor design occur on the perimeter of the building where loads are higher and dynamically changing due to effects of radiation and temperature conduction on the skin of the building.

A recent ASHRAE research project (RP-1373) has also provided data to show that when the height of the air plume to a terminal velocity of 50 fpm (.25 m/s) is limited to 4.5 feet (1.4 m), the air change effectiveness (ACE) is improved in the breathing zone. This research has now been recognized by ASHRAE Standard 62.1-2010 with Addenda A in Table 6-2 by allowing an Ez rating of 1.2 for these conditions. This means that the ventilation (outdoor) air supplied to the zone can be reduced by 16.7%. For LEED projects where the credit point for IEQ credit 2 is desired, this 16.7% can be used in reaching the goal of 30% increased ventilation air.

Some of the biggest challenges for underfloor design occur on the perimeter of the building where loads are higher and dynamically changing due to effects of radiation and temperature conduction on the skin of the building. Where the core of the building is mainly impacted by nearly constant heat loads, the perimeter system must accommodate swings in heat loads and heat losses that can occur in a relatively short period of time.

A common method of handling perimeter loads to locate a fan-powered terminal in the floor plenum near the perimeter. These fan-powered terminals are ducted to outlets located on the perimeter. A typical outlet would be a linear bar grille with either a boot plenum or continuously fed plenum underneath. Equipped with an option hot water or electric heating coil, the fan unit can deliver warm air in response to a space thermostat. Unfortunately, as linear grilles get longer, the mass effect of the discharge air jet projects the air higher than required. If the throw from the outlet is too long and reaches the ceiling, it may deflect downward into the space and create unwanted drafts in the interior zones. In some cases, cool air from the floor plenum is supplied to the perimeter zone through the fan-powered unit.

For LEED projects, the operational cost of energy to run a fan-powered terminal can be minimized by using ECM fan motors. ECM motors operate at an efficiency of 70% or greater. The cooler operation of an ECM motor -- and enhanced construction -- contribute to a longer life and lower life-cycle cost when compared to standard construction PSC motors. An additional benefit of an ECM motor is ability to control the fan speed during operation to provide increased energy savings and better occupant comfort in the occupied space. ECM motors can also utilize remotely controlled speed controllers (pwm) that can be controlled through a building management system.

New technology in perimeter systems can lower installed/operational costs and improve comfort along the perimeter zones. By installing a continuous bar grille along the perimeter, variable air volume (VAV) cooling and plenum heating coils can be attached as needed to condition the perimeter. These cooling and heating units are passive and do not require the use of a fan terminal. The bar grille can be connected together to provide a continuous architectural appearance around the perimeter or can be installed in sections as required for comfort conditioning. The core of the bar grille is removable from the room to provide access to the unit’s working components.

The VAV-cooling units employ an electrically actuated sliding damper, which opens and closes a series of transverse apertures to vary the volume of cool air supplied from the pressurized underfloor plenum into the space. The sliding damper opens and closes to provide the amount of conditioned air required to manage the changing conditions as directed by a room thermostat located in the occupied zone. The transverse apertures manage the supply air to allow room air to be included into the air pattern. Introducing supply air in small bundles helps in managing the projection from the outlet and prevents long throws which create drafts in the occupied space.

The heating plenums also attach to the linear bar grille. The heating plenums are passive in operation and do not require a fan-powered terminal to supply air or heat. Located parallel on the perimeter at the glass, the heating unit mixes the cool convection currents flowing down the glass with warm-air currents traveling across the floor. These mixed currents are induced into the inner chamber of the plenum and flow up through the heat exchanger. The warm current then exits the linear grille at the glass and flow upward via convection to heat the cool air in front of the glass.

The hydronic heating units have a finned-tube heat exchanger with heat supplied through a hot-water pipe and controlled by a water valve to provide the precise amount of heat required to satisfy room conditions. The electric heating units are of fin-tube construction and have an SCR control to match the changing heat requirements in the space. The ETL listed heaters can be found in 120V, 208V, 240V, and 277V supply circuits. The modular construction of the VAV-cooling and the fin-tube water or electric heating units allows the installation to match the requirements of any climate zone. Where winter conditions prevail, more heating units can be installed to meet heating needs. Where hot summer conditions prevail, additional VAV-cooling units can be employed to match the cooling requirements.

To claim maximum energy efficiency and occupant comfort, care should be taken during construction to seal all floor panels. Additional care should be taken to seal all openings through the floor either into the space or into the walls where plumbing or electrical equipment penetrates the floor plenum. Regular inspection during construction will minimize problems upon building completion and commissioning.

In recent years, the application for UFAD systems has shifted from owner-occupied high-tech facilities to a more general variety of building spaces aiming to achieve LEED certification. UFAD provides superior comfort by supplying conditioned air where it is required near the occupant. Additional occupant comfort can be achieved by installing small units in the core of the building with individually adjustable dampers controlled by the occupant. By conditioning only, the occupied area and stratifying the upper zone with air supplied form the low-pressure floor plenum saves energy. Additional energy can be saved by employing a passive VAV-cooling and fin-tube heating system on the perimeter.

For your next LEED project, take advantage of UFAD to provide lower energy (EA c1), controllability of systems for thermal comfort (IEQ c6), and thermal comfort (IEQ c7).

For additional air distribution advice, visit the Titus website.