Aftermarket Service Success Through Reverse Logistics

The three steps for aftermarket service success – stay ahead of the asset based reverse logistics maturity curve

Effective asset or product-based reverse logistics can transform an organization from being just an intermediary to becoming an end-to-end steward for customer needs. But evolving customer demands, business needs and technologies have raised the bar, leaving many just struggling to manage a complex value chain. Tom DeVroy, Senior Product Evangelist at IFS, identifies the barriers of current solutions and explains how more mature reverse logistics engines can help organizations achieve aftermarket service profitability. Here is his three-step plan to lay the foundations of a successful strategy.

Standard parts management and logistics are well-trodden territory for most organizations, but reversing the value chain is not nearly as simple. Mapping and managing the need for parts, anticipating or planning returns and the corresponding depot service is an increasingly complex process—requiring fit-for-purpose tools to maximize efficiency, reduce costs and decrease downtime for customers.

A thoughtful understanding of business potential, coupled with the right technologies, can make reverse logistics increasingly manageable. This leads to a state of maturity among reverse logistics technologies, but businesses cannot afford to stand still once they get there. Reverse logistics, done right, can be a revenue producing business function rather than a cost driver.

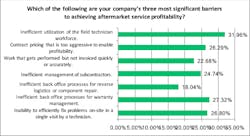

IFS research reveals that a fifth of respondents see inefficient reverse logistics processes as the main barrier to achieving aftermarket service profitability.

Reverse logistics needs to be interwoven with other performance areas such as warranty management, contract management and field service operations. A solid strategy can deliver a positive ripple effect across much of the business.

Research from Aberdeen has shown that the top 20% performing service firms are twice as likely to have reverse logistics in place than the bottom 80%. While reverse logistics planning can seem like a daunting effort, its key elements and considerations can be boiled down to three simple steps.

Step One: Develop a Logistical Map. It is imperative to an organization’s operational success that all reverse logistics activities are handled in a unified, standardized fashion, with returns, depot repairs and part or asset swaps all coded in the same language. Mapping reverse logistics operations means developing a full picture of the different ways parts and assets move between customers, business systems, and warehouse locations. Ask the following questions to discover your unique logistical map:

1. What is the nature of your business? The trajectory of how inventory passes through a system will vary based on whether it is a manufacturer of serviceable assets, seller and servicer of assets, or service provider.

2. Where do items go when they leave the customer? Do items go back to the manufacturer, to specialized repair shops or other specialist locations like central depot, satellite locations or local retail operations that are managed internally?

3. What sort of items pass through your reverse logistics systems? Are full assets or parts being returned, exchanged, or simply in need of repair? Take stock and note whether the pieces are managed by entitlements either by warranty or contract.

4. How do items get to their destination? Customer or business shipping, technician courier or contracted technicians—whatever the delivery method or combination of methods — will provide a key element in getting the big picture of reverse logistics for your company.

Step Two: Leverage the IoT Beyond Serviceable Assets. There are several areas where the Internet of Things (IoT) can enhance reverse logistics operations, beyond parts management. For example, when a customer needs a product or asset swap-out, but the depot is out of the appropriate asset, IoT systems employed across the organization may show that a truck’s inventory includes a refurbished asset of the same type in a technician’s truck, or freshly repaired at a local shop. Having this information and acting on it could save money, improve customer satisfaction and avoid penalties, especially if the service provider’s service level agreement (SLA) specifies a timeframe for repairs. Tracking these temporary loaners, their ownership, location and expected return can all be automated through transformative technology.

Sharing real-time location information gleaned from the IoT with the customer during the repair stages can also help manage expectations and understand downtime. To create sufficient conditions for this, companies need to have systems in place that provide visibility over parts and asset inventory, and measure performance—even if tracking is managed by a fulfillment partner.

Step Three: A Dedicated Software Solution. Every business has different systems, pathways and outcomes attached to its logistical map that represent added layers of complexity to its reverse logistics sequence. This process includes repair, replacement, and complex coordination between locations, as well as information from field service management and inventory systems to technicians and vehicles.

When considering technology implementation, organizations cannot compromise operational integrity and muddle internal processes that already function seamlessly. Reverse logistics is not simply parts management in reverse, and as such, cannot be managed by an elementary parts management solution. A specialized and sophisticated solution will deliver dedicated reverse logistics capabilities, organize a firm’s unique complexity and provide a 360-degree view of every piece of the service puzzle—without disrupting its operational harmony.

Getting the full picture pays dividends. Reverse logistics is evolving, so service organizations must keep up too. Mapping out business needs, visualizing the reverse supply chain in motion, centralizing vital service information and making the right software choices can all influence how well they will be able to manage the challenges and capitalize on the opportunities represented by reverse logistics. Planning should never be a throwaway element of this—the right approach can turn a complex process into a competitive advantage.

Author: Tom DeVroy, Senior Product Evangelist, North America at IFS

Tom DeVroy has over 30 years of experience in high tech service operations including work with hardware, software and consulting firms, as well as premier global service organizations like Ericsson, DHL, Xerox, and Ingenico. He holds a degree in business administration from the University of Wisconsin-Parkside.