Understanding Your Company’s Service Operations

A client came to me and asked that I examine her financial statements. She was puzzled by the fact that she had record sales but made less money than she had the year before. My client’s company generated $3,356,540 in total sales with a net profit of $107,953 or 3.22%. She should be at 10% NPBT (net profit before taxes) with 15% being ideal.

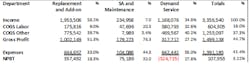

Her income statement combined all her company’s financial numbers. We needed granular detail to know what happened. We created three departments: demand service, replacement/add-on, and service agreement/maintenance. This is not an ideal set of departments, but it was the best we could do at the time. We separated the income, cost of goods sold, and overhead by these departments.

Here is how my client’s departmentalized income statement broke down:

I am sure you can image how surprised my client was by the huge loss in her demand service department. This was not a surprise to me. We often see this. Most companies do not departmentalize their income statements, so they have no idea where they make money and where they lose it. That is a very dangerous way to run a company.

The demand service department is arguably the most important department in an HVAC company. It is also where most contractors lose money. I asked her what department caused her the most stress. Not surprisingly, she said that it was the demand service department. Service departments are generally the most difficult to manage due to their high labor-to-sales ratio.

Typically, add-on and equipment replacements offer the most profit for an HVAC company. That was the case for my client as she made over $357K doing that type of work. Unfortunately for her, those tremendous profits were almost completely offset by the huge losses in the demand service department. The good news for her is that we now knew the immediate problem, and it was fairly easy to fix.

Fixing Demand Service: First Priorities

The problem with her service department is gross profit is more than 50% higher than it should be. Labor costs are too high. Her demand service labor costs are 32.6% of sales. They should be 21% or less.

We performed a thorough breakeven analysis. We adjusted her labor rates and modified her parts markups. This straightened out gross profit margins. We typically get a lot of pushback from owners when discussing raising prices. Not this time. I only had to point my finger at the $324,725 loss that this department created for her. That is all it took.

Preventive maintenance is in everyone’s best interest. Out of all the things that you offer, preventative maintenance is the easiest to explain and advertise.

Not long ago, I worked with this client to move from time and material pricing to flat rate pricing. I was disappointed to learn that she had not gotten that task done. She was letting her technicians quote T&M whenever it suited them. We wrote new policy to finalize the transition to flat rate pricing.

We created a truck stock list that allowed technicians to avoid profit killing trips to suppliers. We included a reasonable assortment of IAQ products and other accessories. Techs will be far more likely to sell these items if they have them on hand.

Finally, we scheduled a weekly thirty-minute team “huddle.” This weekly briefing will be led by the service manager. This dedicated time offers the manager an opportunity to act more like a coach to his/her coworkers.

Fixing Demand Service: Phase 2

There was more I wanted to do, but it would have to wait. Later, my hope is to see her adopt performance-based compensation. This will include an incentive program for all employees.

We have a weekly team “huddle,” but we also need a more thorough training program. Topics will include presentation and communication skills, advanced system diagnostics, indoor air quality, and replacement lead generation.

Changing Our Marketing Priorities

Replacements and add-ons are where the money is, at least it is for my client’s company. Now that we have fixed her immediate demand service-related issues, we turned our attention to driving more replacement sales.

Where should your add-on and equipment replacement sales leads come from? Thirty percent should come from demand service work. Twenty percent should come from planned maintenance work. Twenty-three percent should come from client referrals. No more than 27 percentshould come from external paid sources.

Most contracting companies should think of themselves primarily as a service agreement company. Preventive maintenance is in everyone’s best interest. Out of all the things that you offer, preventative maintenance is the easiest to explain and advertise. Service agreements also create the most shareholder value because they create cashflow and recurring revenue.

We worked on a plan to market and advertise precision tune-ups as a loss leader. We would train technicians to convert precision tune-ups and demand service calls into service agreement sales. Our goal is to convert at least 60% of tune-ups and 25% of demand service calls into a service agreement sale.

More Replacement Opportunities

Precision tune-ups lead to service calls. Precision tune-ups and demand service calls lead to service agreement sales. All these things lead to add-on and replacement sales, her most profitable work.

With demand service losses under control and more add-on and replacement income, my client has laid the groundwork to much higher profit. I am looking forward to her next quarterly financial report.

To continue learning about service management operations, and how service departments can become a measurable profit center for contracting companies, visit EGIA.org/CBS-Operations and download a free package of training resources complete with online class, sample metrics & benchmarks, how-to documents on establishing a profitable service rate, and much more!

James Leichter is a founding faculty member at EGIA Contractor University. Learn more about EGIA and Contractor University. He is a longtime HVAC contractor, consultant, and public speaker. Leichter is president and CEO at Aptora Corporation, a maker of contracting business management software. He is the editor of MrHVAC.com and BlackBeltContracting.com. James is a majority shareholder at RA Tax and Accounting, Inc.