On Oct. 13, 2009, the Air-Conditioning, Heating, and Refrigeration Institute (AHRI) signed an agreement with environmental advocates led by the American Council for an Energy-Efficient Economy (ACEEE) and other groups, notably the California Energy Commission. This agreement establishes several precedents: First, the consensus agreement calls for the Department of Energy to adopt regional standards for furnaces, central air conditioners and heat pumps, replacing the national standards approach that has long been in effect. Table 1 gives the values recommended to the DOE. The agreement also calls on Congress to allow states to adopt somewhat higher performance expectations in their state energy codes for residences. Other parts of the agreement will improve the information available to distributors and contractors, potentially improving the ability to differentiate the right product for each customer.

When adopted by Congress and the DOE, the move from national to regional standards will change business operations. Change can be scary, particularly in a depressed business environment. In this note, I'll try to give a little background and make some guesses about how implementation might work — and how distributors might profit, making lemonade with your customers out of the proverbial lemon you think this change could be.

National minimum-efficiency standards for furnaces, air conditioners and heat pumps took effect in 1992. Standards-setting by the Department of Energy has been acrimonious. The law mandates setting standards at the “maximum level that is technologically feasible and economically justified.” Environmental advocates and some utilities have pushed for more stringent standards, while manufacturers have resisted. Both sides make good cases. Manufacturers, distributors and contractors all worry that more stringency makes it harder to show cost-effective savings from premium products. Because better installation, such as the ACCA QI program, creates huge, well-documented savings, we all have a stake in avoiding selections based on Low Bid instead of Best Value.

Another problem with efficiency standards has been that the rating methods aren't very good and get worse as the equipment gets better. They don't do a very good job of helping consumers arrive at good choices for their houses, and they don't help contractors sell the best products for those homeowners. One reason is that the air conditioner laboratory tests don't approximate field conditions very well. For example, duct defects generally require much more fan power than the test assumes and affect both air flow/dehumidification and energy use.

But the most important reason is that the United States has many different climates. The right furnaces in Michigan and Minnesota are certainly condensing ones with at least 90 AFUE. These might not be cost-effective in Mississippi, but the federal process has required a “one-size-fits-all” approach.

Similarly, contrast what we need from air conditioners in Arizona vs. Alabama. In the hot, dry West, about the only thing that matters economically is performance at high outdoor temperatures. One third of the cost of air conditioning in Sacramento occurs when outside temperatures rise above 90°F. But, this gets only 7.4 percent of the weighting in SEER, the federal “score” for air conditioners. For California, Arizona and similar states, EER95 is a better predictor of air conditioner performance than SEER. Conversely, in hot, humid climates, what matters most is how well the air conditioner removes humidity at part load, when the outside temperatures are in the upper 70s and 80s. Enhancing dehumidification (lower SHR) tends to reduce SEER, at least for low-end equipment. We think that a major consideration preventing manufacturers from cutting corners to improve SEER at the expense of dehumidification is fear of callbacks associated with mold.

These considerations led ACEEE to start work on the potential gains from regional standards years ago. With our research partners and help from an industry advisory committee, we published our recommendation for considering regional standards. The Energy Independence and Security Act (EISA) of 2007 provided instructions on how to proceed. Since then, we've worked with manufacturers and others on how to make this work to save energy and help industry. I want to stress that it's not the only thing we're doing: For example, we're actively evaluating the potential for early replacements of obsolete but functional equipment, as a stimulus and to save energy. Stay tuned.

What the agreement does

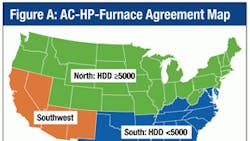

The AHRI-Advocates agreement will establish two regions for furnaces and three for air conditioners (Figure A). The boundary between “northern” and “southern” is the boundary between states with average winter intensity above 5,000 DD, versus warmer states. Condensing furnaces (AFUE ? 90) are required in the North; we recommend an 80 AFUE limit in the South. Air conditioner regions differ only in that there is a separate four-state “hot-dry” region with minimum EER as well as SEER requirements, to assure minimum high-temperature performance levels. The 5,000 DD boundary was a compromise involving many considerations. Climate mattered most, but we also tried to minimize the number and size of metropolitan areas that straddle a boundary, to reduce the number of affected contractors and distributors as much as possible. Table 1 gives the values proposed to DOE as the maximum feasible and justified.

Page 2 of 3

The agreement does not address one key area: enforcement. Current law is clear: No one can manufacture or import for sale in the United States any product that does not meet federal minimum-efficiency specifications. The new law (EISA) requires DOE to carry out a separate rulemaking on enforcement mechanisms for regional standards, if adopted. This is not yet scheduled. Enforcement may become the responsibility of state and local code officials, which might fit their increasing responsibilities under ARRA, the stimulus bill of 2009. In this scenario, contractors would be liable if they installed nonconforming equipment. Better approaches may be developed, and all of us look forward to HARDI's participation in developing a good system, one that will help deliver efficiency by assuring excellent installation of the right equipment.

Who will win?

Yogi Berra famously observed, "Prediction is hard, particularly the future." With this warning, let me think with you about how this agreement would fit in with other trends in the industry to help people win in the new environment. This is tentative, because I'm not an expert on your business, and because we don't know the details of the agreement's implementation. The sidebar expands a bit on the ¡°fine print¡± of the agreement. We think that some parts may offer huge new opportunities to savvy firms.

First, the manufacturers have agreed to offer much more engineering data for their products. Most envision this as part load EER data at multiple points, as well as the sensible heat ratio at 82 degrees. This information will allow firms such as WrightSoft and Elite to develop better energy-use estimators in their load calculation programs, adding to the climate data they already can incorporate. We expect that smart distributors and contractors (and manufacturers) will use these capabilities to support much better and more credible proposals for customers. It will be easier to select ¡°good-better-best¡± options, and present both benefits and savings in a compact form to support intelligent customer choice.

Behind the proposal, which is the "consumer interface," the best contractors and distributors will gain more ability to look at trade-offs among similar products, the effects of oversizing, the benefits of better air handlers and many other options. Ultimately, showing that many trade-offs don't make much difference may help reduce stocking requirements rather than increase them. Sure, the distributors who serve both sides of a regional border will still stock minimum-efficiency equipment for all their customers, but they will also have new capabilities to help their customers move up to greater efficiency and long-term savings.

We expect that better information will lead to more finely tuned incentive programs from utilities and government, too. We already see EER requirements in EnergyStar, for example. Southeastern programs might well seek low SHR values (high dehumidification capability) to assure comfort and protect against mold ¡ª for their protection and yours.

So, at the risk of someone accusing me of lunacy, I see a future in which the best distributors become more tightly coupled to contractors. In one foggy vision, the distributor owns the estimating and proposal software. ¡°Interactive¡± proposal development lets the contractor know stock status for each option, including the parts ¡°kits¡± required for the job.

Of course, there're likely to be multiple solutions: some extensions of OEM-based software, some distributor-hosted and some ¡°contractor-centric.¡± But everyone in the whole chain will have to think about how to take advantage of the new information and new environment to profit by serving customers better.

As long as I'm speculating, think about what smart information systems and direct delivery to the job site could do for you and your customers, at least for metro areas. What if your countermen took truck-based ¡°mini-warehouses¡± on the road to a contractor site, with a combination of equipment kits and most commonly needed items? For smart contractors, this could be a win-win situation: paying you more to avoid stocking while assuring prompt availability. And maybe your ¡°counterman¡± can help move the equipment into place, avoiding that second contractor employee standing around much of the time.

Will there be losers?

With this agreement, business will change and that will be hard for some people. But business is always changing, with ever more requirements for customer support. One question that has arisen is whether consumer choice will suffer. On Nov. 23, the AHRI directory included more than 200,000 single-phase AC systems (OEM, not including mix-and-match) at SEER 14 and higher, the highest level proposed for the South or Southwest. The directory included 2,540 condensing furnaces (AFUE ¡Ý 90), the level proposed for the North. In general, this sounds like excellent availability already. We're confident that, in the time remaining before the new rules would take effect, the OEMs can fill any gaps they feel might be profitable. Indeed, the effective dates were staggered to help them allocate resources effectively.

Page 3 of 3

We also hear concerns that state boundaries are too crude because there are huge climate variations within many states. For example, California recognizes 16 different climate zones for energy purposes. Some wanted much finer-scale regulation, but in the end, the agreement reflects the parties' best judgment on what is achievable now. Where there are ¡°anomalies,¡± such as cold parts of a hot state, rebate programs may encourage better equipment in some counties, but states cannot require equipment efficiencies beyond the federal minimum for the state. Surely, there is less consumer harm with this approach than the prior one, which left the South with relatively inefficient air conditioners and the North without requirements for condensing furnaces.

There's another compromise, too, one that was a big deal for me. After all the research on the value of different rating methods for different regions, we compromised for the 2015 round: For that one, we will not have true regional ratings, just different stringency levels in the different regions. For example, we won't have a maximum sensible heat ratio for the southern climates, something that would have helped assure good dehumidification. The manufacturers felt strongly that multiple ratings were problematic now. But, they will provide engineering data to help you as distributors make the best possible recommendations to your customers for their customers.

Discussion

At ACEEE, we believe that much greater energy efficiency is necessary for America's future ¡ª and can be a key to profitability for those who grasp the opportunity. In part, that's because the regional standards are just one piece, although a critical one, in a broader set of changes that are coming to the building industries. As noted above, regional standards are likely to require local compliance responsibility. This goes along with separate efforts to ensure that building codes are actually enforceable and enforced. Initially, this primarily impacts new construction, but we think its extension in various ways will help professionalize the contracting industry. We expect much more use of building-energy-use labels, particularly at times of real estate transactions. If we're right, this automatically boosts the value of efficiency investments, because it helps assure customers a return on their investments if they sell before the equipment life is over.

We don't know if the basis for this kind of labeling will be inspections ("energy audits" such as HERS ratings) or utility bill analysis ¡ª or both in some jurisdictions. We are certain, though, that this will help contractors and their suppliers better differentiate quality products and services and generally "up sell" to greater profitability. I hope this works for you.

Harvey Sachs is a senior fellow in the Buildings Program at the American Council for an Energy- Efficient Economy, where he has worked for nine years. His work includes emerging technologies, market acceleration and equipment standards. He is active in several ASHRAE committees. Contact him at 202/507-4014 or [email protected].

<45,000 Btu/h

14 SEER/11.7 EER

¡Ý45,000 Btu/h

(weatherized)

(non-weatherized)

(non-weatherized)

The Fine Print

The parties agreed that new construction should be ready for higher future energy prices. So, they adopted language that would allow somewhat higher equipment efficiency ratings to be used in the default or ¡°baseline¡± building for Code purposes ¡ª if there is at least one way that builders can meet the code with minimum-efficiency equipment. We believe that this will stimulate the sales of more efficient equipment into the ¡°builders special¡± market, if builders choose to use higher efficiency equipment instead of other ways to improve performance. This should benefit distributors, particularly when rebates align with the Code provisions. By the way, this provision does not apply to the ¡°one-for-one replacement¡± market; it is only for new construction.

The temperature bins will be extended upward to 117 degrees and the rating method will be based on population-weighted national bin data. However, multiple (regional) ratings of the same air conditioner are not allowed in the 2015 standards.

Models that are already certified when the 2015 standards take effect will not require recertification before 2018, easing the certification burden with the development of new products.

Sensible Heat Ratio and Product Performance Data

Of particular interest in the South, manufacturers will make available the sensible heat ratio (SHR) at 82¡ãF for all air conditioner and heat pump models. SHR governs dehumidification capability, so this information will be helpful to specifiers and rebate sponsors who are concerned about both comfort and mold. Similarly, manufacturers will make estimated equipment performance data by temperature bin available to contractors, program sponsors and software developers to support the capabilities outlined in the main text. AHRI will neither certify nor verify this data.

Comments regarding Harvey Sachs' article

Paragraph 1: Congress is allowing states to set guidelines. This is dangerous. We have seen the results of those making decisions who do not understand nor listen to input from those working in the industry. There have been examples of towns and villages making rules requiring 90% [efficiency] equipment, both boilers and furnaces, without truly investigating how such installations can be done.

Paragraph 3: Manufacturers and distributors worrying about cost-effective savings. I believe we should all be emphasizing comfort as well as efficiency, as they go hand in hand.

Paragraph 5: I strongly concur with his comments on ¡°cutting corners¡± at the expense of dehumidification.

Who Will Win? Section: Having a counterman or other distributor personnel move equipment into place? Mr. Sachs has to realize the burden that builders and contractors put on distributors already. To ask for this to happen would bring not only additional operating costs per employee but also raise insurance and liability issues that only add to the demise of a distributor's minimal ¡°bottom line.¡±

Building Code Changes section: There should be a mandate for builders to build efficiently, not cheaply as they have done. It is quite clear through the last building boom, especially, that builders have been given free rein to find the cheapest install at the sacrifice of efficiency and comfort to the clients they purport to have in their best interest. Just go out and look at some of the junk they built.

¡ª Bill Reidinger, manager, Control'd Engineering Supply, Glen Ellyn, IL

No specific comments [about Mr. Sachs' article], although I feel it is written from an optimistic viewpoint with less concern shown for the negative impact it will have on consumer prices, especially those that are locked into 80% furnaces given their current venting configurations.

¡ª An East Coast Distributor