Finding the Right Solutions Drive Grundfos

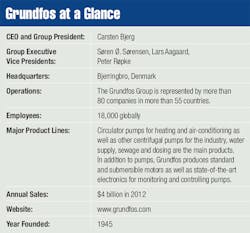

As a global company, Grundfos serves five regions around the world and reported $4 billion in sales last year. Its North American operations accounted for about a half-billion dollars of that total. Grundfos has an aggressive plan for growth over the next four years. According to Søren Sørensen, group executive vice president and chairman of the North American board, Grundfos plans to grow its sales in North America to $1 billion by 2017. As evidence of its commitment to growing this market, Sørensen and other Grundfos officials joined Illinois Gov. Pat Quinn in April for a ceremonial groundbreaking of Grundfos’ new North American corporate headquarters in Downers Grove, IL.

Grundfos began as a company in 1945 with one small factory in Bjerring- Finding the Right Solutions Drive Grundfos bro, Denmark. Today, it comprises more than 80 companies with more than 18,000 employees worldwide. The company specializes in circulator pumps for heating and air conditioning as well as centrifugal pumps for industrial applications, water supply, sewage and dosing. Grundfos also manufactures standard and submersible motors and state-of-the-art electronics for monitoring and controlling pumps.

Grundfos established a presence in North America in 1973 and today has manufacturing operations in Fresno, CA; Aurora, IL; Indianapolis, IN; and Brookshire, TX. The company also operates a distribution center in Allentown, PA. Its U.S. headquarters, along with its research and development center and call center, are in Kansas City, KS. Today, the U.S. portion of the North American market is split fairly evenly among the building trades, municipal water supply and industrial markets, says Dennis Wierzbicki, president of Grundfos USA.

On the hydronics side, Grundfos has traditionally had a large presence in the European residential market and it continues to look for ways to grow that market in the U.S. – in both the residential and commercial markets. “We’re introducing more new technology on this side in the building trades market than anywhere else,” Wierzbicki says.

Grundfos has some fantastic technologies that offer opportunities for commercial building owners to manage their energy costs. “Everybody’s looking at building management systems and managing costs on the heating and cooling side,” he adds. Grundfos’ hydronics products offer a great deal of differentiation with such advances as smart pumps that adjust based on the operating conditions.

Growing Grundfos’ presence in the North American market has largely come through organic growth, Wierzbicki says. In segments where the company had traditionally not been as strong, acquisitions have helped to build the business.

For example, Grundfos had done well in the residential and home heating markets but did not have a significant presence in the commercial market. Its acquisition of PACO pumps helped to complete an important piece of the company’s business. “PACO has a strong presence in the building trade market, and it was a product that we needed,” Wierzbicki says.

Its acquisition of Peerless Pump, one of the largest manufacturers of vertical pumps in the industry, helped to build its portfolio in the fire pump market. This acquisition, like others made by Grundfos, has not only helped Grundfos in the North American market but around the world. “Peerless was not only an acquisition to help us in the U.S. but to help in global markets with fire pumps,” Wierzbicki says. “We now have a fire pump package we compete with globally.”

At 40-years-old and still considered a relative newcomer to the North American market, the PACO and Peerless acquisitions added great visibility to Grundfos as they were long-standing and well-respected brands. Wierzbicki notes that PACO has more than 100 years of history in the U.S., while Peerless began as a Los Angeles-based company 90 years ago.

Research and development figures heavily into how Grundfos plans to continue its growth trajectory. The focus in its R&D efforts is on energyefficient, cost-effective products. R&D centers in Denmark, China and the U.S. work collaboratively on new product development while also adapting some of its global products to the U.S. market. Circulator pumps, for example, that were developed in Europe have been successfully adapted for the U.S. market through Grundfos engineering and then tested in homes – many in the homes of the installers themselves – before they came on the U.S. market.

Recognizing that contractors and installers need to see and touch the products, Grundfos has an active sales network of salespeople and independent reps that works closely with wholesale distributors to make its products accessible to them. More than 100 Grundfos salespeople in the U.S. work closely with distributors through joint sales calls, being on a job site to answer questions or participate in training sessions.

Wierzbicki says Grundfos salespeople share their knowledge, but they also get a lot back from the contractors and installers. Their feedback goes directly back to the R&D centers as engineers and designers make enhancements. “They’re the ones who have to put the equipment in and repair it,” he says of the contractors and installers. “We count on them as some of the best advertisers for our products.”

The salespeople and independent reps actively visit distributors and their branch locations. “We rely very heavily on our wholesalers, and our reps are out there with them,” he says. Much of their time at the branch locations focuses at the counter. After all, Wierzbicki notes, the contractors will often rely on the advice of the counter staff when they’re purchasing a part or a piece of equipment. By working with the counter salespeople, the sales rep provides a deeper understanding not just of how a Grundfos product works, but its value to the contractor’s customer, particularly related to the energy efficiency and savings that come with such a product.

Because Grundfos serves three distinct markets – municipal water, industrial and building trades – it has different ways of selling to those markets. “We’re not locked into one channel,” Wierzbicki says. “We always look for how we can best service the local market. You’ve got to find the distributor that fits what you’re looking for.”

There may be Grundfos distributors in the same geographic market, but they may be selling to distinct markets within that area. “It does create challenges,” Wierzbicki says. “We try to find people who understand that and work well together.” It’s about which distributors have the most expertise in the particular market and can be the most effective partner for those customers.

With its focus on innovation and technology that result in energy savings, Grundfos looks for wholesale distributors who share this philosophy. Wierzbicki admits that not every distributor may be a right fit for Grundfos. He says distributors that have a solutionbased approach to customer service are the ones who fit the Grundfos model. “What are the solutions that will help save the customer money?” Wierzbicki says of the Grundfos philosophy.

Because Grundfos has worked so closely with its end user customers, it recognizes their particular needs. Grundfos is focused on how its products can help building owners reduce their overall operating costs. “They can’t go out and charge more rent. They’ve got to find a way to manage their costs better.” There’s a renewed focus, Wierzbicki says, on finding longer-lasting, more reliable HVAC products, and Grundfos is gaining traction as a result.

Better products that are in line with the needs of customers will drive future growth for Grundfos as well as its distribution partners. Those businesses that aren’t focused on customer solutions risk falling into a trap of being known as entities that sell only products. In today’s highly competitive HVAC and hydronics markets, that’s not good enough. “The building trades and contractors are looking for someone who can help them,” Wierzbicki says. “They’re counting on wholesalers and manufacturers to bring them that expertise. We have to make sure we continue to provide that expertise and knowledge.”

Giving its customers a voice back to the manufacturer is also an important piece of the relationship that is not lost on Grundfos. Wierzbicki says Grundfos’ website (us.grundfos.com) offers the opportunities to find the sales rep in a local area. There’s also an 800 toll-free number that can either direct them or answer their question over the phone.

Another challenge that Grundfos is actively working to address is bringing talented people into this industry. To get young people motivated to be part of the HVAC industry, Grundfos partners with local universities in the cities where it has a presence to provide classrooms with products and other support tools so they experience the types of technologies that are making a difference in efficiently heating and cooling buildings.

Wierzbicki says the Grundfos Challenge has been a way to engage engineering students to think about and provide solutions to some of the major environmental challenges in the world today. In the 2013 Global Grundfos Challenge, for example, Grundfos challenged students from Denmark, China and the U.S. to find a solution to improving London’s water supply problems.

The challenges posed to the students are the same ones that Grundfos engineers are working on every day. These are the very same challenges that present some of the greatest opportunities for Grundfos. Finding ways to address the aging infrastructure of municipal water systems is one big area of focus, Wierzbicki says, noting that the leakage rate from these systems averages about 30 percent. “They can’t find or fix the problems and they don’t have the money to solve them,” he says of the water suppliers. “So we’re very much participating there.”

Adapting aging buildings to more efficient HVAC systems is a second area of focus. “We have a huge focus on building management and energy savings to help reduce overall energy use in this country and keep them running more efficiently,” he says.

For Grundfos, this focus on energyefficient solutions is interdependent with its robust research and development and building the relationships with its distributors and end user customers. They all fit together to form partnerships that create more value for everyone.

|

Best Practice Technical Training and Employee Development Definition: Grundfos North America operates two important training organizations: the Grundfos Technical Institute and the Poul Due Jensen Academy. For business partners, the Grundfos Technical Institute offers a comprehensive portfolio of product, application and market-based training, equipping representatives and distributors with the tools necessary for success in the pump industry. For employees, the Poul Due Jensen Academy at Grundfos’ global headquarters provides extensive career development training with the help of satellites in the U.S., China, Russia and India. Benefits: A knowledgeable sales force and a well-educated staff are key to the successful implementation of products in the market, as well as the health of Grundfos’ business. Example: Before the U.S. sales launch of the MAGNA3, one of the company’s most innovative new products, Grundfos held internal training classes to get its sales and support staff up-to-date on the pump’s numerous technological capabilities. Shortly before the MAGNA3’s release, the Grundfos Technical Institute in Olathe, KS, hosted more than 200 sales representatives and distributors for the domestic and commercial buildings market for extensive training. During the two-day session, the trainees explored the innovative functionalities of the MAGNA3. They had the opportunity to tour the lab, test out working demos and interact with the products’ engineers in order to get comfortable with the technology. In addition to receiving training on the technical details of the products, attendees were also trained on presenting with maximum effectiveness. Contact: Helen Mubarak, public affairs coordinator, [email protected]. |