Questions about the accuracy of airflow readings are a hot topic around our industry and in other related trades. Let's look at several airflow principles you can apply to increase your skill and confidence in your airflow measurements.

Back to Basics

The foundation of accurate airflow measurement is an airflow traverse. We'll use a simple 6-in. x 12-in. duct as an example.

The basic rectangular traverse formula is VELOCITY (The average measured airspeed in feet per minute) X AREA (The measured and calculated open area of the duct or air stream in square feet) = CFM (Cubic Feet of Minute of airflow).

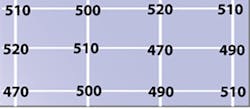

The illustration is as through you’re looking into a cutaway of the duct at the point where 12 velocity readings have been taken.

1. Add together the 12 velocity readings to find the velocity measurements add up to 6,000 feet per minute (fpm).

2. Divide 6,000 fpm by 12 velocity measurements to find the average velocity in this duct is 500 fpm.

3. Next, calculate the area of the duct. It measures 6-in. x 12-in., or 72 sq.in.

4. Then convert the duct area of 72 square inches into square feet. Divide 72 by 144 (or the number of square inches in a square foot) to discover the duct is .50 square feet.

Careful: If you forget to divide duct square inches by 144, you'll end up with CIM or Cubing Inches per Minute. We don't usually use this measurement in HVAC.

Now that you have all the information, work the formula:

500 feet per minute average velocity x .50 square feet of duct area = 250 Cubic Feet per Minute of airflow. Or, 500 fpm x .50 sq. ft. = 250 cfm.

Here are a couple of examples to paint a clearer picture:

1. Change the duct area to 1 square foot: 500 FPM x 1 sq. ft. = 500 CFM.

2. Then, change the air velocity to 1000 feet per minute: 1000 FPM x 1 sq. ft = 1000 CFM.

3. Now, change the duct area to 2 square feet (12-in. x 24-in.).

4. 1000 fpm x 2 sq. ft. = 2000 CFM.

As you test in the field, velocity and area will change with each airflow test. Sorry, but in the field, your measurement will rarely add up to such perfect round numbers.

The traverse principle applies to every traverse of a duct, a grille or registers, an outside air inlet, or a fume hood in a laboratory. A balancing hood is a mechanical device that creates a traverse of the air flowing into or out of the grille.

Airflow Test Location

Accurate airflow measurements depend on the correct test location. There are certain locations within an HVAC system where you cannot accurately measure airflow.

An ideal airflow measurement location is in a long straight duct. Install test ports to insert your probe 80% downstream in the duct and 20% upstream from the end of the duct.

You cannot measure airflow accurately near the inlet of discharge a fan. Air is too turbulent at these points in a system. Plus, testing too close to an elbow or transition will produce unsatisfactory results as well.

Correct Instruments and Accessories

Just as an HVAC system has airflow test locations that are better than others, some test instruments are better suited for certain airflow test applications.

Fortunately, most air measurement instruments include data capture and calculation functions that allow you to enter the test data with the push of a button. It makes airflow calculations and air density corrections and calculates cfm directly for you.

Rotating Vane Anemometers are best for measuring airflow at the face of a supply or return grille, at an economizer inlet, or when measuring kitchen exhaust airflow.

Thermal or Hot Wire Anemometers have a small diameter, compact tips that can be inserted into t ductwork and are suitable for other applications.

Pitot Tunes and Programmable Micro-manometers are better in commercial applications where airflow moves at higher velocities. These two instruments enable increased accuracy. Today, more HVAC manufacturers install pressure ports on their equipment, and you can easily convert measured pressure to cfm.

A Traverse Litmus Test

ASHRAE Standard 111 provides a mathematical test to verify if the velocity measurement gathered for a traverse fall within acceptable limits. An experienced balancer uses this test often when reviewing reports.

The rule says if 75% of the air velocity readings are between the highest velocity reading, and 10% of the highest velocity reading, then the test data is acceptable.

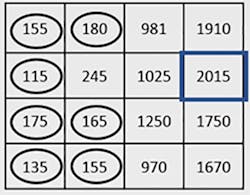

To apply this test, review the velocity readings on the traverse report. Draw a box around the highest velocity reading and multiply it by .10 or 10%. Then circle each reading smaller than 10% of the highest velocity reading. Next, count each of the circled readings.

Finally, divide the number of circled readings by the highest velocity reading. The result will give you the percent of out-of-range readings. If less than 25%, you're good to go. If greater than .25 or 25%, either repeat the traverse or find a more suitable test location.

Figure 2 Example:

- 2015 fpm x .10 = 201 fpm.

- The number of circled readings below 201 fpm is 7.

- 7 ÷ 6 = 44% of readings are lower than 10% of the highest velocity reading.

- 44% of readings are less than 10% of the maximum velocity. Since it exceeds the maximum of 25%, this traverse fails the litmus test.

Accurate airflow measurement requires a working knowledge of airflow testing and skill developed through repeated traverse testing. Whether you're a seasoned professional or new to airflow measurement, these traverse principles, when applied, will increase your ability to accurately measure and interpret airflow.

Rob "Doc" Falke serves the industry as president of National Comfort Institute, Inc., an HVAC-based training company and membership organization. If you're an HVAC professional interested in a free airflow traverse report and procedure, contact Doc at ncilink.com/ContactMe or call him at 800-633-7058. Go to NCI's website at nationalcomfortinstitute.com for free information, articles, downloads, and current training opportunities.

About the Author

Rob 'Doc' Falke

President

Rob “Doc” Falke serves the industry as president of National Comfort Institute an HVAC-based training company and membership organization. If you're an HVAC contractor or technician interested in a building pressure measurement procedure, contact Doc at [email protected] or call him at 800-633-7058. Go to NCI’s website at NationalComfortInstitute.com for free information, articles and downloads.