Helping your team understand the importance of proper duct system design and installation can be challenging. Since air is invisible, it may be hard to visualize how it moves through a duct system. It helps to use our imaginations and compare air movement to something simple and relatable instead of an abstract concept that few understand.

Everyone has been stuck in traffic or driven too fast on the interstate, so we understand the cause-and-effect relationship between vehicles and roads. That also serves as a great analogy for duct design and installation. Let's look at how you can relate traffic and what affects it to help installers, salespeople, and technicians get the best performance from a duct system.

Airflow is the Vehicle

Vehicles are the first factor contributing to traffic. To help your team understand the importance of airflow, have them think of each cfm (cubic feet per minute) of airflow as a single-vehicle.

Vehicles and air are valuable boxes moving along a road to get to a destination. Each vehicle contains precious cargo (the people inside), while each cfm contains Btus the customer pays for to make their home comfortable. It's the driver's job to ensure a vehicle arrives safely and intact at the destination. Similarly, it is the installer's job to assure the delivery of equipment Btus to the right rooms.

Vehicles move at different speeds measured in mph (miles per hour), while we typically measure airflow in fpm (feet per minute). The faster a vehicle moves on a road, the higher the mph. The faster air moves through a duct, the higher the fpm.

There's a reason for speed limits. A vehicle moving at a reasonable speed has a better chance of reaching its destination than one driving too fast. On a straight interstate, it's common to have a 70-mph speed limit. However, an old country road with lots of turns might have a speed limit of only 25-mph.

Airflow and vehicles have turning limitations based on speed. The higher the speed, the more critical the turn. The lower the speed, the less critical the turn. For example, a car driving 70-mph cannot make a sharp, 90-degree turn. It would end up flipping and wrecking. However, if the vehicle were going 15-mph, it would be much easier to make that sharp turn.

We understand this with vehicles but forget to apply the same principle to duct systems. Air traveling at 700 fpm through a return duct also cannot make a sharp turn. The action results in excessive turbulence and higher pressure drop across duct fittings. But if you increase duct size and slow the speed down, turns have less impact on airflow performance.

Ducts are Roads

Roads are the second factor contributing to traffic. Depending on where you're traveling, you might drive on an interstate or secondary road. Since airflow is the vehicle to transport Btus throughout a building, you want to construct duct systems like good roads.

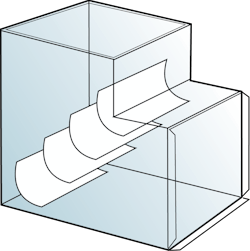

Occasionally you'll encounter a lane closure while driving. Some conditions give you plenty of time to merge into another lane. Others back up traffic for hours, like when there's a wreck. Duct transitions act as merging lanes for airflow.

When you change duct sizes, an ideal transition should taper on both sides at a 15-degree angle or less. This gradual change minimizes turbulence and keeps air moving smoothly. Avoid tapers of 45-degrees or more, so you aren't creating unnecessary lane closures and traffic delays in your duct systems.

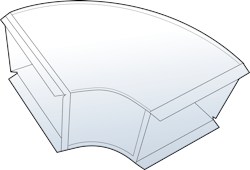

As you travel, you'll eventually need to exit the main road or turn onto a secondary road. Depending on how fast you're driving, the change in direction must be gradual, or you'll zoom right past your turn. Duct fittings should act as exit ramps. Well-designed fittings provide air a smooth path to turn and change directions without slowing down unnecessarily.

Well-designed duct fittings provide air a smooth path to turn and change directions without slowing down unnecessarily.

Remember, the air is moving at a high speed, so it needs an easy way to turn and exit, just like a car leaving the interstate. To apply this principle to your duct systems, select fittings with low equivalent lengths. Equivalent length is how we express duct fitting resistance in terms of straight feet of duct. You can find these values on the back of most duct calculators and in the appendix of ACCA Manual D. The better the duct fitting, the lower the equivalent length.

Look at the last duct system your installation team finished. Is it straight like a city street or winding like a gravel country road? How easy is it for air to change directions? Are your fittings sharp turns or smooth and gradual? I bet there's a teachable moment in your inspection.

The Examples are Endless

If you use your imagination, you can come up with many comparisons of your own. Try it yourself and see what you come up with to better help your team connect traffic and airflow. Here are a couple more to consider.

A good zone system helps determine airflow direction based on differing load conditions. The dampers automatically direct air to "stop" or "go" and send conditioned air where needed.

Another comparison is to think of zoning systems as a traffic control for airflow. Sometimes you don't need air going to certain places in a building. A good zone system helps determine airflow direction based on differing load conditions. The dampers automatically direct air to "stop" or "go" and send conditioned air where needed.

Every Road Has a Designer and Builder

Engineering teams design how the road should work and provide detailed plans and instructions for its completion. Construction companies work from engineered plans to bring their design to life. It takes both groups working together to bring what looks good on paper into reality.

We assume design equals reality. It doesn't always and that assumption is killing the airflow performance of many HVAC systems. Most duct systems do not perform because there's a disconnect between the designer and the installation team.

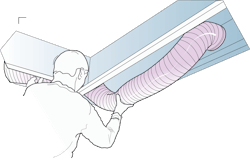

If you're a duct designer, guesses don't cut it. You need measurements and proven design methods to achieve the best airflow highway for a customer to invest in. Just because you design something on paper doesn't mean it magically happens. The installation team makes the magic happen. They are responsible for making a duct system work like it's supposed to under some challenging conditions.

Once the duct system installation is complete, proper air balancing makes sure the design works and helps air move as the designer intended. You cannot air balance a duct system that's poorly designed, undersized, or has leakage. You only achieve these three aspects of a duct system when the designer and installers work together.

The next time your team looks at a duct system, have them think of it as an airflow highway. Ask them how well they believe traffic would flow if it were a road. To further emphasize this point, Loren Cook, a manufacturer of various air-moving products, has a great Youtube video that makes air visible. If you want to help your team understand the importance of a duct system, I encourage you to share it with them.David Richardson serves the HVAC industry as director of technical curriculum at National Comfort Institute, Inc. (NCI). NCI specializes in training that focuses on improving, measuring, and verifying HVAC and Building Performance.

If you're an HVAC contractor or technician interested in learning more about how to improve airflow traffic, contact David at ncilink.com/ContactMe or call 800-633-7058. NCI's website www.nationalcomfortinstitute.com is full of free technical articles and downloads to help you improve your professionalism and strengthen your company.

About the Author

David Richardson

Director, technical curriculum

David Richardson serves the HVAC industry as director of technical curriculum at National Comfort Institute, Inc. (NCI), Avon, Ohio. NCI specializes in training that focuses on improving, measuring, and verifying HVAC and Building Performance.