Performance Boils Down to Btu

Last week, an unprecedented heat wave plagued most of the country. I thought back to my contracting days and remembered the unpleasant feeling of stress that came with having more work than I knew how to handle. It was almost worse than the anxiety you feel during the slow periods.

This morning, I sat on my porch sipping my morning (hot) coffee, feeling the humidity weigh on me like a heavy wool blanket. I was snapped out of my daydream when my phone buzzed with a new text message notification. It was a friend of mine sharing his latest HVAC sizing story from the field. For this story, I will refer to him as “Jim.”

Jim pulled up to the jobsite for today’s installation. He has been working a lot of hours, so he was mentally and physically exhausted. However, today seemed to be a bit of a reprieve, since he was only installing a new condenser and evaporator coil, while keeping the existing furnace.

New Equipment, Same Old Problems

He removed the old system and brought all the scrap outside just as the delivery truck arrived with the new equipment. They started unloading the truck, and he immediately noticed the new condenser and evaporator coil were 4-ton models.

He spun around to glance back at the townhome and saw it was a middle unit (shared side walls with the neighbors). Think of a shared side wall in the same way you would think about an interior wall; there is no Delta T (ΔT) across the wall, so no heat gain occurs.

The front of the first floor was an attached garage with a partition wall. These walls differ from exterior walls because there is a lower ΔT across the wall, which equates to reduced heat transfer. The townhome had three exterior surfaces that were subject to substantial heat gain: the back of the house, the front of the house, and the second-floor ceiling.

Jim’s gut was warning him against replacing the existing 4-ton system with a like-for-like size. The easy answer would have been to run a Manual J load calculation and then confirm the correct equipment size. However, the clock was ticking, and we all know that time is money.

Jim called his supervisor and explained his concerns, and he was told, “We size our systems so our customers can be comfortable when it is 100° outside.”

History Repeats Itself: But Less Often

Listening to this story made me wonder: How many times has the temperature in Chicago reached 100° F in the past 30 years? So, I looked it up. The answer is 10. People are sizing systems for world-ending “worst case” conditions that we have only seen 10 times since I was a freshman in high school, and Bill Clinton was making news swinging around his saxophone. I took a sip of my coffee, and another question popped into my mind.

Why Are We Afraid?

The word that comes to mind when considering the answer is bugaboo. A bugaboo is something that causes unnecessary fear or anxiety, not based on reality. However, when we consider the actual data, we can shift our focus back to reality.

The total volume of fan airflow directly impacts sensible, latent, and total Btu. Sensible Btu are the heat energy that increases or reduces the temperature displayed on a thermostat. Latent Btu are considered invisible heat. When you think of latent, think of the amount of humidity in the air. Total Btu are the sum of sensible and latent combined. To understand the performance of any system, you have to start with fan airflow.

If you increase fan airflow, you increase the sensible and total capacity while decreasing the latent capacity. And vice versa: if you decrease fan airflow, you decrease total and sensible heat while increasing the latent capacity. What does this mean? Spoiler alert: The existing 4-ton system won’t deliver anywhere near four tons of capacity.

A Data-Driven Approach

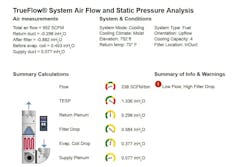

It is becoming more common for companies to pressure profile systems (taking essential static pressure measurements) and measure total fan airflow during estimates. The 4-ton equipment that Jim is replacing was moving less than 2.5 tons of airflow. By examining the performance data for the existing system, Jim discovered that the manufacturer doesn’t provide data for 238 cfm per ton. The system is operating outside of normal operating conditions.

The performance table is of no use if the equipment is operating with inadequate airflow. Three equations will help determine the actual operating capacity of existing equipment.

1 Total Heat Formula = 4.5 x CFM x ∆H

2. Sensible Heat Formula = 1.08 x CFM x ∆T

3. Total Heat – Sensible Heat = Latent Heat

Where:

4.5 = 0.075 lbs/ft³ x 60 minutes per hour

∆H = Difference of enthalpy between the return and supply

1.08 = 0.075 lbs/ft³ x 0.24 Btu/lb. x 60 minutes per hour

∆T = Difference of temperature between the return and supply

If you use these formulas, you can calculate the delivered capacity of any existing system. Pretty cool, right? Using these formulas takes the unnecessary fear of reducing the size of existing equipment by proving that your 4-ton is not operating as a 4-ton.

Push Comes to Shove

Jim’s installation manager ultimately agreed to install a three-ton system instead of the four-ton system that was shipped. The smaller equipment will most likely operate more efficiently than the larger four-ton system.

Sizing residential HVAC equipment shouldn’t be a negotiation, but rather a methodical process. What are a few issues that could arise if the townhome only required two tons of cooling? In a few years, we will find out.

As HVAC professionals, all of our recommendations and decisions should be based on numbers and data, not bugaboos. Consider these two quotes and remember them the next time you’re tempted to swap like-for-like equipment.

“When you can measure what you are speaking about, and express it in numbers, you know something about it. When you cannot express it in numbers, your knowledge is of a meager and unsatisfactory kind.” – Lord Kelvin.

“If you don’t measure, you’re just guessing.” – Rob Falke.

If you’re an HVAC contractor or technician interested in learning more about equipment performance, contact Adam at ncilink.com/contactme. NCI’s website, www.nationalcomfortinstitute.com, is full of free information to help you improve your professionalism and strengthen your company.