With six months to go until January 2010, and the EPA mandated limitation on R-22 supply, service technicians will need to make some basic choices about the use of R-22 and alternatives they will need to use. R-22 will not be allowed for new equipment and the options for which HFC to use will be limited and directed by the equipment manufacturers. Existing R-22 equipment built before January 2010 will be allowed to use R-22 that is manufactured after January 2010, or use reclaimed R-22. As long as R-22 is available in sufficient quantity and at an attractive price, then it will still be used for service. Although this market situation might hold going into next season, eventually the rising price of R-22 will make the use of retrofit blends economically attractive.

There are many blends being marketed for retrofitting and technicians need to make an informed choice. People are asking the question, “What should I use to replace R-22?” It sounds like a simple question, and yet the answer will depend on several key factors.

New Equipment

Air conditioning manufacturers have standardized on R-410A for new equipment. Because it has higher pressure and higher capacity than R-22, it can’t be used to retrofit existing equipment. Some manufacturers have designed some specialty AC units around R-407C, but economics favors the use of R-410A in most residential and light commercial applications. R-410A condensing units can be smaller than equivalent R-22 or R-407C units, saving on the amount of metal used.

In refrigeration, there has been a comprehensive selection of equipment available for R-404A and R-134a for many years now. As R-22 is no longer applied in new systems after January 2010, equipment using these other choices will still be available right out of the catalog.

Retrofitting Existing R-22 Equipment

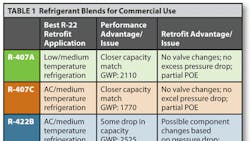

A wide variety of blends have been advertised as R-22 retrofit refrigerants, including R-404A, R-407A and C, R-417A, R-421A and B, R-422A, B, C, and D, R-427A, R-428A, R-434A, and R-438A. Many of these blends have very similar components or different ratios of the same components. All of these blends come close to the properties of R-22 at some temperature, but none of them match R-22 at all temperatures. Some of these blends will be better at matching the properties of R-22 in a given system than others. Unfortunately, there does not seem to be one “best” blend to use for R-22 retrofitting. {Some of the more readily-available commercial blends are summarized in Table…} Several of the key issues affecting the choice of a retrofit blend are:

Air Conditioning versus Refrigeration. There is a fundamental difference between these two applications: evaporator temperature. R-22 air conditioners, with evaporator temperatures from 35ºF to 50ºF, will behave much differently than refrigeration systems running at 20ºF (med temp) or -20ºF (low temp). Different blends will match R-22 properties in AC and others will be better suited for lower temperature operation.

Application of Equipment. Another difference might be design capacity and run time for the intended application. Air conditioners are sized for the worst few days of the year and will cycle considerably most of the time. AC can tolerate lower capacity blends by simply running a little longer. “Storage” refrigeration applications are also sized for 18 to 20 hours run time during the day. Lower capacity blends can also be tolerated in these systems because there is room for longer run times. Where systems are sized to match the capacity of the load, or seem to be running all of the time, blends with higher capacity will be needed to maintain equipment performance.

Size of Equipment – Ease of Retrofit or Service. Smaller, self contained refrigeration equipment or air conditioners will generally involve much less work to service or retrofit. If major parts need replacement, it may often be easier to replace the entire unit. Blends that require component replacements or major oil changes may not be the best choice. Service of larger installations will more likely involve component replacement and planned retrofits can be more comprehensive in terms of leak repair, seal or gasket replacement, oil changes, or adjustment of controls, which opens up the choice of retrofit blend.

NOTE: If a technician is replacing a compressor during a service call, the system can be recharged with any of the new blends if the new compressor contains POE. Regardless of the size of a system, this is an opportunity to pick the best environmental or performance option since most of the work required to retrofit is already being done for the compressor change.

Does the oil need to be changed?

Hydrofluorocarbon (HFC) refrigerants don’t mix with mineral oil. Manufacturer’s traditional recommendations for retrofitting to HFCs have required 3 oil flushes to get the mineral oil content below 5% in the new polyol ester (POE) oil charge. The fear has been that residual mineral oil would either react with the POE or remain separate and clog valves or cause heat transfer problems. In reality, the chemical reactions seen years ago with POEs came from residual process chemicals and waxes used in manufacturing motors and heat exchangers, not from the mineral oil. These impurities have been eliminated from the manufacturing process for many years now. Also, POE and mineral oil mix so well that there will not be mineral oil “blobs” gumming up the system.

Partial POE. Tests are being conducted in a wide variety of refrigeration and air conditioning equipment to show that relatively small amounts of POE can be used to circulate mineral oil. In a partial POE retrofit, only some of the mineral oil is removed and replaced with POE. The POE mixes with the mineral oil, and the resulting mixture can dissolve into the liquid on the high side of a system and still remain fluid enough to return on the suction side as well.

Hydrocarbons. Many of the new blends contain hydrocarbons to help mineral oil circulate throughout the system. The hydrocarbons soak into the oil and lower the viscosity, allowing the refrigerant to push the thinner oil around the system. While this works well to move oil back along a suction line, studies have shown that mineral oil can accumulate in a liquid receiver since the hydrocarbon does not help mineral oil dissolve into liquid refrigerant. Oil in a receiver will float on top of the refrigerant and not be drawn out so it can return to the compressor. Smaller systems, without receivers, will probably work very well with the hydrocarbon blends and no oil change.

Some blend manufacturers have recommended that if oil circulation becomes a problem in a hydrocarbon–containing blend, then adding POE will solve the oil circulation problem. What this means is that HFC blends will experience oil circulation with partial POE addition regardless of whether hydrocarbon is used or not.

Summary

Technicians are being offered a wide variety of R-22 alternatives and an ever-shrinking amount of time to decide which one will work best for their business. One person’s favorite will certainly not be the best choice for all. It is time to choose what to use for new equipment installations. In addition, it is time to consider the type of equipment, application conditions, and complexity of a retrofit project and compare these to the properties of the retrofit blends available to find your best option. Do your research and ask a lot of questions.

Jim Lavelle is the technical sales manager for National Refrigerants, Inc., Philadelphia, PA. He can be reached at [email protected]