REFRIGERATION BASICS: Optimizing System Performance Using a TXV

EDITOR'S NOTE: This article was updated to include a video review of HVACR Metering Device Basics.

The thermostatic expansion valve (TXV) is a precision device designed to regulate the rate at which liquid refrigerant flows into the evaporator. This controlled flow is necessary to prevent the return of liquid refrigerant to the compressor.

The TXV separates the high pressure and low-pressure sides of a refrigeration or air conditioning system. Liquid refrigerant enters the valve under high pressure, but its pressure is reduced when the TXV limits the amount of refrigerant entering the evaporator.

Remember, the TXV controls only one thing: the rate of flow of liquid refrigerant into the evaporator. The TXV is not designed to control air temperature, head pressure, capacity, suction pressure, or humidity. Attempts to use the TXV to control any of these system variables will lead to poor system performance and possible compressor failure.

Remember, the TXV controls only one thing:

the rate of flow of liquid refrigerant into the evaporator.

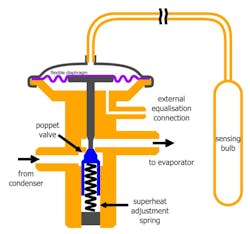

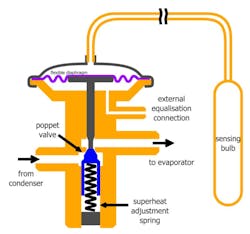

The TXV responds to the temperature of refrigerant gas as it leaves the evaporator. This temperature is detected by the sensing bulb, which is located near the evaporator outlet (Figure). The TXV also responds to the refrigerant pressure within the evaporator, which is transmitted to the TXV by an equalizer line. By responding to these variables, the TXV maintains a predetermined superheat within the evaporator. This is how the TXV keeps the system in balance and operating properly. To understand how this works, we must have a clear understanding of superheat.

Superheat

Superheat is the difference between two temperatures:

- the saturation temperature of the refrigerant (i.e., the temperature at which the refrigerant changes from a liquid state to vapor. This is the same as its boiling point. For water at sea level, the saturation temperature is 212°F. The saturation temperature of liquid increases as pressure increases.

- the actual temperature of the refrigerant (i.e., the temperature of refrigerant vapor by the time it reaches the evaporator outlet).

Example of superheat:

- A refrigeration evaporator is operating with R-22 refrigerant at 69 PSIG suction pressure; its saturation temperature is 40°F. This is the temperature at which the refrigerant evaporates from a liquid into vapor.

- As the refrigerant moves along the coil, it absorbs heat from the environment surrounding the coil, until the liquid is evaporated.

- The refrigerant vapor continues to absorb heat from the environment around the coil, and its temperature continues to rise. At this point, it's superheated.

- If refrigerant temperature has risen to 50°F, by the time it reaches the evaporator outlet its superheat is 10°F (50°F - 40°F = 10°F). The amount of superheat is the result of two variables: how much refrigerant enters the evaporator, and how much heat the evaporator is exposed to. Both high and low superheat can cause problems.

When superheat is too low, the point at which all the refrigerant is finally evaporated occurs very close to the evaporator outlet. When this happens, it's possible for liquid refrigerant to be fed back into the compressor, where it will cause serious damage.

When superheat is too high, the liquid refrigerant is fully evaporated long before it reaches the evaporator outlet. As a result, the temperature of the refrigerant vapor continues to rise, raising the superheat of the gas in the suction line from the evaporator to the compressor.

For every one degree rise in the suction gas temperature entering the compressor, there is a corresponding one-and-a-half degree rise in the discharge gas temperature. This can lead to poor system performance and overheating of the compressor. By controlling the rate at which high-pressure refrigerant is released into the evaporator, the TXV controls the amount of superheat that will occur.

Basic TXV operation

The TXV controls superheat by controlling the flow of liquid refrigerant. As it does this, it also reduces refrigerant pressure.

- Liquid refrigerant enters the TXV under high pressure.

- As the flow of liquid refrigerant is reduced, its pressure drops.

- The refrigerant leaving the TXV is now a combination of low-pressure liquid and vapor.

As the flow is restricted, several things happen:

- The pressure on the liquid refrigerant drops

- A small amount of the liquid refrigerant is converted to gas, in response to the drop in pressure

- This “flash gas” represents a high degree of energy transfer, as the sensible heat of the refrigerant is converted to latent heat

- The low-pressure liquid and vapor combination moves into the evaporator, where the rest of the liquid refrigerant “boils off” into its gaseous state as it absorbs heat from its surroundings.

Changes in gas temperature at the evaporator outlet are detected by the sensing bulb, which then causes the valve pin to move in or out, regulating the flow of refrigerant through the TXV. In this way, the valve allows just enough refrigerant into the evaporator, to maintain the correct level of superheat in the suction line.

How the TXV Controls Superheat

The TXV controls superheat by varying the size of the orifice through which the refrigerant flows. The pin angle, the size of the stroke (typically 0.015- to 0.035-in.) and the diameter of the orifice itself all affect how much refrigerant can pass through the valve. In addition, all valves have some leakage around the valve pin, although this is normally kept within acceptable limits.

It's important to remember that valve capacity is a function of the orifice diameter, pin angle, and stroke. Adjusting the superheat spring doesn't change valve capacity.

Al Maier is vice president, applications engineering for Emerson Climate Technologies, Flow Controls. Graphics courtesy Emerson Climate Technologies. emersonclimate.com.