Supermarket Reaps Benefits from A2L Refrigerant

The legacy R-744 carbon dioxide (CO2 ) system, still commonplace in the industry, could potentially be outperformed by A2L HFO refrigerants on a number of metrics, including overall energy efficiency, a study by independent consultants predicted. The results of the 2021 upgrade, representing a world-first switch from R-744 to R-454A in a supermarket application, proved more promising than had been expected.

• 34% energy saving

• Yearly energy saving: £41,7k ($52,000)

• Lifetime CO2eq saving: 1,099 TCO2

• TCO saving (20years): £1,33M ($1.7 million)

• Potential saving projected over entire ASDA fleet: £776M ($989,322).

Since the implementation of the European F-Gas regulation EU 517/2014, the direct emissions ratings of refrigeration systems have become synonymous with their sustainability. The GWP rating of refrigerants, therefore, has taken center stage as the end-all criteria in the fight against climate change. This has led to a heavy focus simply on global warming potential in the event of a refrigerant leakage, without due consideration to total emissions being produced every day, including the power consumed by a refrigeration system.

There are also new proposals from the EU to further limit the quantities of refrigerant gas available on the market, which are under consideration for the next iteration of the F-Gas regulation, due in 2024. Post Brexit, UK authorities are conducting a similar review and will apply the EU agreement as a benchmark for their own regulations, which could decisively impact the current Great Britain quota.

The Benefits of Shopping Around

In 2007, major UK retailer ASDA, continuously committed to addressing the grand challenge of our time, opened their flagship sustainable store-of-the-future in Bootle, Merseyside. As is common practice, ASDA opted for a “natural” refrigerant, R-744 CO2.

Though the system operated with a stable energy profile over 14 years, high maintenance requirements and degradation soon left the Bootle supermarket looking forA previous study by independent consultants Wave Engineering was conducted for ASDA comparing the Total Emissions (TEWI) and Total Cost of Ownership (TCO) of various alternatives. Analysis from data collected by Wave in such studies was published by Chemours in a white paper “The Path to Reducing Climate Change Emissions from Commercial Refrigeration Applications“.

This report showed that viable alternatives to R-744 CO2 exist and that newly developed A2L refrigerants based on HFO technology such as those in the Opteon™ XL range can offer an excellent balance of sustainability, safety, and total cost of ownership. The pioneering work of ASDA and partners has overcome barriers to use of these new fluids in commercial retail refrigeration.

The Bootle Supermarket project is a shining example of how a major retailer such as ASDA, working with theirTaking stock

ASDA’s Bootle supermarket initially deployed a Trans-critical R-744 CO2 booster system during the 2007 reconstruction, comprised of two centralized medium temperature racks and one low temperature rack with one common remote gas cooler.

While the system functioned as expected, regular inspections and maintenance identified that the system’s insulation had degraded over time, leading to significant deterioration of the equipment. During its 14-year lifetime the system proved maintenance-hungry and required the replacement of the gas cooler after just five years, due to corrosion and vibration damage.

To maintain the Bootle location as their flagship sustainability-focused supermarket, with a key focus on energy efficiency and safety, ASDA chose to revamp the entire site in 2021, and install brand new low-GWP refrigeration systems using Opteon™ XL40 (R-454A) throughout, with each system engineered to meet the requirements of F-Gas, BSEN-378, ATEX and DSEAR.

It is likely that ASDA Bootle is the world’s first large supermarket to fully operate in a direct expansion configuration on a low-GWP A2L refrigerant. Proudly, ASDA Bootle can decisively claim another impressive title: being the first store that has replaced a transcritical CO2 refrigeration system with an A2L HFO-based solution, and seeing significant and immediate results. The project was completed in 2021 and involved replacing:

Centralised R-744 CO2 packs – running 135 m Chilled and 48.75 m Frozen display cases with:In addition to lowering energy consumption, ASDA have reduced refrigerant leakage in new and refurbished installations to below 3% per annum of the total system charge – further evidence of how GWP ratings as a standalone metric for the environmental impact of refrigeration systems is wholly insufficient. Using a more pragmatic and holistic TEWI (Total Equivalent Warming Impact) calculation shows that despite Opteon™ XL40 R-454A having a higher GWP than R-744, the total emissions from the new Opteon™ XL40 system are a full 29% lower than the previous R-744 system (Figure 4).

This emphasizes the importance of taking a wider, real-world view and performing a full analysis when seeking solutions with the lowest environmental impact, rather than looking at systems in isolation. The indirect CO2 emissions, attributed to electrical power generation, remain the major factor contributing to global warming in the case of this refrigeration system, hence the importance of energy efficiency in achieving emissions reduction.

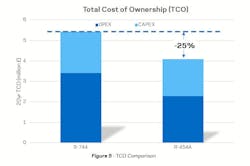

Lifetime TCO

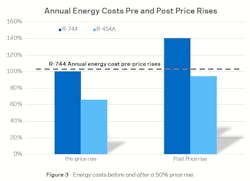

Another key factor to consider is the Total Cost of Ownership (TCO) over the lifetime of the equipment, which interestingly, can play a significant role in the environmental impact of a system as well. In real-world scenarios, when maintenance costs prove prohibitive, regular interventions and servicing may be skipped or reduced, augmenting the risk of system failure, and refrigerant leakage. Energy costs are currently the largest contributor to OPEX (Operating Expense) and the recent stresses on global energy supply and the associated increase in electricity prices have brought this into stark focus. The cost of equipment, installation (Capital Expenditure or CAPEX) and maintenance is also very significant when comparing CO2R-744 to an A2L gas, which is more akin to the HFC systems now being replaced.Combined with its lower energy consumption, this gives the new HFO-based system an overall twenty-year TCO which is an impressive 25% lower than the R-744 system being replaced, as shown in Figure 5.

The cost savings in just one store are significant, but when multiplied across the whole estate, ASDA estimated, at only 50% increase in current energy cost levels, a potential minimum £750 million reduction in total energy costs over 20 years, compared with using the R-744 CO2 technology previously employed at Bootle.Change for the better

Through careful analysis of the data collected over several years culminating in the practical example of the Bootle Supermarket, ASDA have concluded that HFO-based technology best meets their criteria: excellent performance, minimal risk to trade, low energy consumption, competitive cost of ownership and ease of installation and maintenance.

Never resting on their laurels, ASDA’s commitment to eliminating carbon emissions is an example for the industry. As perspectives shift from a narrow view of GWP ratings to a more holistic and tangible measure of a system’s TEWI, solutions such as Opteon™ XL’s range of low-GWP HFO refrigerants are proving that the best approach – is balanced.

Case study provided by Chemours. chemours.com