As A2L Transition Moves Forward, Refrigerant Leak Detection Comes into Greater Focus

The transition of HVAC manufacturers towards A2L-based systems across various parts of the globe has continued to drive ahead during the past few years, and the push toward that new platform has put a spotlight on the leak detection system needs of those systems and the ones which will follow.

Environmental Factors Driving Refrigerant Shifts

The roots of the transition to A2L tie back to the original Montreal Protocol, developed by the United Nations and ratified in 1989 to protect the ozone layer by banning release of chemicals like chlorofluorocarbons (CFCs), which had been commonly used in HVAC equipment, aerosols, and other applications.

Many companies shifted their refrigerant platform toward hydrofluorocarbons (HFCs). While those compounds did not deplete the ozone layer, the tradeoff was a significantly elevated global warming potential (GWP), creating an outsized effect on global warming.

The Kigali Amendment, ratified by the United States in 2022, moves to phase out HFCs around the globe reducing their use by 80 to 85 percent by the late 2040s in developed countries. Overall, the trend in refrigerant technology and approach over the past 40+ years has been the continued movement toward systems with a reduced GWP and overall lower environmental impact.

Flammability and A2L Creates Leak Detection Needs

A2L refrigerants have a far less GWP than the HFCs they are replacing, but they introduce another factor to consider – flammability.

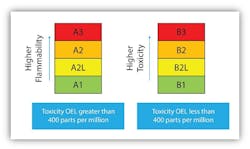

In this context, chemicals are generally classified in terms of both flammability and toxicity according to ISO 817.

Chemicals in category A3 are considered less toxic, but highly flammable – such as propane. While chemicals at B1 may not be flammable, they are toxic. A2L chemicals are slightly flammable but are less toxic.

In order for a flammable refrigerant to create an incident, two conditions must be met

· the refrigerant must be present in a high enough concentration

a spark or ignition event must occur

The use of these compounds in HVAC settings led to development of UL60335-2-40. Because systems may be placed in areas where sparks cannot be fully controlled, this standard is designed to prevent the former condition from taking place by detecting the presence of refrigerant and initiating mitigation measures to safely remove it.

The regulation requires that manufacturers evaluate each refrigerant based on its lower flammability limit – the concentration of gas required to ignite.

As flammable refrigerants continue to expand across the globe, the need for leak detection across a variety of mediums will continue to become more and more widespread.

For R454A (as an example) – that LFL is 0.278 kg/m³. R290 is much more flammable, so its LFL is far more restrictive – A3 Gases generally have an LFL of ≤ 0.10 kg/m³ or high heat at combustion ratings.

UL regulations take the LFL for that specific refrigerant/refrigerant blend, and require that the system require a leak detection and mitigation system prevent the concentration of gas from reaching 25% of that value – providing a significant safety margin.

Other key aspects of the UL guidelines require

· The sensors must be factory set and sealed with no field adjustment permitted

· Self-test protocols run every hour to ensure proper operation and function

· The sensor cannot be affected by poisoning due to common household and workplace contaminants which trigger false alarms or nuisance trips

Commercial and Consumer End of Refrigerant Leak Detection

While the global goal of reducing global warming impacts is necessary, the challenge for HVAC OEMs is that all of this new technology is an added cost to each system which the end consumer may not fully understand – putting an additional premium on the need for a robust system which will not require additional maintenance or decrease the overall working life of the unit.

The Sensata Resonix™ RGD sensor – the result of a multi-year development process - was designed to deliver the performance and reliability OEMs need for these next generation of platforms.

It delivers a fast response time with a life expectancy of more than 15 years – often exceeding the lifetime of the equipment itself. Because the sensors do not require field calibration or re-zeroing, they reduce service costs for both installers and end users.

As flammable refrigerants continue to expand across the globe, the need for leak detection across a variety of mediums will continue to become more and more widespread. Regulations managing leak detection for R290 systems are already in process, and other refrigerant platforms may enter the fold in the future.

The steps laid out under the Kigali Amendment to reduce and eliminate the use of HFCs is intended to keep more than 100 million tons of carbon dioxide equivalent of greenhouse gases from the atmosphere. By 2100, that effort will have hopefully helped to avoid up to 0.5 degree Celsius of global temperature rise. Looking ahead, further enhancements in HVAC system design will continue to take shape, driven by the focus on safety, environmental impact, and energy efficiency worldwide.

Richard Rodrigues is the Senior Global Product Manager for Sensata Technologies’ HVAC Gas Sensing product line. Richard has 14 years of product development experience in industrial sensing, professional lighting, environmental sensors, and additional product categories. sensata.com

About the Author

Richard Rodrigues

Senior Global Product Manager

Richard Rodrigues is the Senior Global Product Manager for Sensata Technologies’ HVAC Gas Sensing product line. Richard has 14 years of product development experience in industrial sensing, professional lighting, environmental sensors, and additional product categories.