UPDATED WITH REFRESHED DIAGRAMS and PDF FOR DOWNLOAD

A thermostatic expansion valve (TXV) is built up around a thermostatic element separated from the valve body by a diaphragm. Its purpose is to regulate the rate at which refrigerant flows into the evaporator.

TXVs can contain one of three different types of charge:

- universal charge

- maximum operating pressure (MOP) charge

- MOP charge with ballast (standard for Danfoss expansion valves with MOP).

Expansion valves with universal charge are used in most refrigeration systems where there is no pressure limitation requirement and where the bulb can be located warmer than the element or at a high evaporating temperature/evaporating pressure.

Expansion valves with MOP charge are typically used on factory-made units where suction pressure limitation on starting is required such as in the transport sector and in air conditioning systems. All expansion valves with MOP have a very small charge in the bulb. This means that the valve or the element must be located warmer than the bulb. If it's not, charge can migrate from the bulb to the element and prevent the expansion valve from functioning.

Expansion valves with MOP ballast charges are used mainly in refrigeration systems with "high dynamic" evaporators, such as in air conditioning systems and plate heat exchangers with high heat transfer.

Installation Procedures

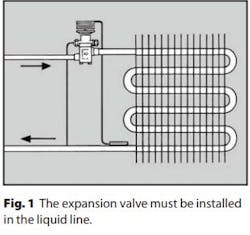

The expansion valve must be installed in the liquid line, ahead of the evaporator, with the bulb fastened to the suction line as close to the evaporator as possible. If there's external pressure equalization, the equalizing line must be connected to the suction line immediately after the bulb. (Figure 1)

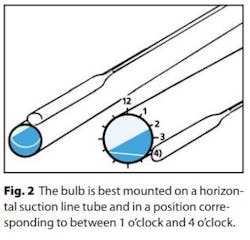

Note: The bulb must never be located at the bottom of the suction line due to the possibility of oil laying in the bottom of the pipe causing false signals.

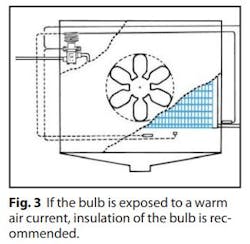

If the bulb is exposed to a warm air current, insulation of the bulb is recommended. (Figure 3)

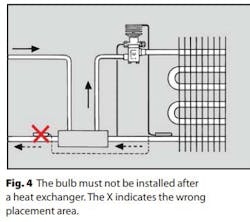

As previously mentioned, the bulb must be installed to the horizontal part of the suction line immediately after the evaporator. It must not be installed to a collection tube or a riser after an oil pocket. The expansion valve bulb must always be installed ahead of any liquid lock.

How the TXV Controls Superheat

The thermostatic expansion valve (TXV) is a precision device designed to regulate the rate at which liquid refrigerant flows into the evaporator. This controlled flow is necessary to prevent the return of liquid refrigerant to the compressor.The TXV separates the high pressure and low-pressure sides of a refrigeration or air conditioning system. Liquid refrigerant enters the valve under high pressure, but its pressure is reduced when the TXV limits the amount of refrigerant entering the evaporator.

Remember: the TXV controls only one thing: the rate of flow of liquid refrigerant into the evaporator. The TXV is not designed to control air temperature, head pressure, capacity, suction pressure, or humidity. Attempts to use the TXV to control any of these system variables will lead to poor system performance and possible compressor failure.

The TXV responds to the temperature of refrigerant gas as it leaves the evaporator. This temperature is detected by the sensing bulb, which is located near the evaporator outlet. The TXV also responds to the refrigerant pressure within the evaporator, which is transmitted to the TXV by an equalizer line. By responding to these variables, the TXV maintains a predetermined superheat within the evaporator. This is how the TXV keeps the system in balance and operating properly. To understand how this works, we must have a clear understanding of superheat.

Superheat is the difference between two temperatures:

- the saturation temperature of the refrigerant (the temperature at which the refrigerant changes from a liquid state to vapor. This is the same as its boiling point. For water at sea level, the saturation temperature is 212F. The saturation temperature of a liquid increases as pressure increases.

- the actual temperature of the refrigerant (the temperature of refrigerant vapor by the time it reaches the evaporator outlet).

The TXV controls superheat by controlling the flow of liquid refrigerant. As it does this, it also reduces refrigerant pressure.

Liquid refrigerant enters the TXV under high pressure. As the flow of liquid refrigerant is reduced, its pressure drops. The refrigerant leaving the TXV is now a combination of low-pressure liquid and vapor.

As the flow is restricted, several things happen:

- The pressure on the liquid refrigerant drops;

- A small amount of the liquid refrigerant is converted to gas, in response to the drop in pressure;

- This "flash gas" represents a high degree of energy transfer, as the sensible heat of the refrigerant is converted to latent heat;

- The low-pressure liquid and vapor combination moves into the evaporator, where the rest of the liquid refrigerant "boils off" into its gaseous state as it absorbs heat from its surroundings.

Changes in gas temperature at the evaporator outlet are detected by the sensing bulb, which then causes the valve pin to move in or out, regulating the flow of refrigerant through the TXV. In this way, the valve allows just enough refrigerant into the evaporator, to maintain the correct level of superheat in the suction line.

The TXV controls superheat by varying the size of the orifice through which the refrigerant flows. The pin angle, the size of the stroke (typically 0.015- to 0.035-in.) and the diameter of the orifice itself all affect how much refrigerant can pass through the valve. In addition, all valves have some leakage around the valve pin, although this is normally kept within acceptable limits.

It's important to remember that valve capacity is a function of the orifice diameter, pin angle, and stroke. Adjusting the superheat spring doesn't change valve capacity.

— Al Maier, vice president, applications engineering, Emerson Climate Technologies.

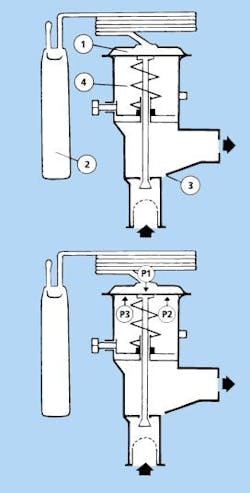

A thermostatic expansion valve works like this (refer to Figure 5):

DANFOSS TXV FAULTS CAUSES AND REMEDIES

One Technician's TXV Advice

The thermostatic expansion valve (TXV) is like the carburetor in your car's engine. It opens and closes to allow the correct amount of refrigerant into your system. When the TXV isn't working properly, the efficiency of your unit is crippled. If you suspect you have a faulty TXV, perform these tests:First, connect your gauges to the system and check that the refrigerant pressures, subcooling and superheat are where they should be (for pressures settings, refer to unit's pressure chart; for subcooling -- usually around 10F -- and superheat (between 8F-12F) follow manufacturer's specification sheet.

Check to see if airflow through the system is good . There should be no dirty coils or air filters. Also check for proper CFMs readings across the system.

Make sure there's the right amount of refrigerant charge in the system (this step may require weighing out the refrigerant in the system). Once you've added or removed charge as necessary, check the pressures, subcooling and superheat again. If there is no change then it is probably the TXV.

Check the evaporator coil and remove the TXV's sensing bulb from the suction line.

Check the subcooling, superheat and pressures again. If there's no change, that's a further indication of a TXV problem.

Another test is to put the sensing bulb in ice water and checking the pressures superheat, and subcooling again. If they don't change, it's a bad TXV.

— Eloy Saban, owner, Temp Contol LLC, Nashville, TN