Contractors, Distributors Warming Up to R-410A

Increasing numbers of HVACR contractors and distributors are stepping up their efforts to transition away from R-22 refrigerant, according to a new survey conducted by Emerson Climate Technologies, St. Louis, MO, a business of Emerson.

The latest Emerson contractor and distributor survey, designed to measure readiness for the 2010 transition away from R-22 equipment, reveals that while only 11% of respondents reported that they’re exclusively quoting R-410A, 70% reported they currently quote both R-410A and R-22. Sixty four percent reported they’re training their staff to service and install R-410A equipment , an 11% increase over the survey sent six months prior.

Customer Interest Growing

A key finding of the latest survey is that increasing numbers of customers are requesting R-410A equipment: 15% percent of those surveyed reported that more than 40% of their customers are requesting R-410A equipment. That figure is up from 10% as reported in the previous survey.

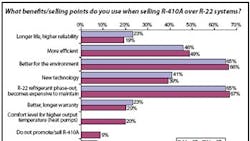

Emerson links this trend to the increasing concern among end-users that equipment show improved efficiency and environmentallyfriendliness, as well as the growing awareness that R-22 equipment will become expensive to maintain in future years. Two-thirds of those surveyed said they cite both environmental concerns and long-term costs when explaining the benefits of R-410A equipment to their customers.

“We’re glad to see that more HVAC professionals are beginning to transition their business toward R-410A bearing equipment in advance of 2010,” says Scott Barbour, president, Emerson Climate Technologies air conditioning division. “This latest survey tells us that the industry is accelerating the transition, but we need to continue increasing the forward momentum, to ensure we’re all prepared to provide the best, most responsible options for our customers.” According to Barbour, contractors and distributors are already reporting what are described as “significant” price increases for replacement R-22 refrigerant. Therefore, the industry must focus on the realities of long-term cost and availability of replacement parts and refrigerant, and thus the importance of making the switch to HFCs, such as R-410A, as quickly as possible.

Thirty nine percent of survey respondents say they will wait until 2010 to convert the majority of their sales to R-410A equipment. Reasons given for recommending R-22 equipment over R-410A included retrofit concerns and short-term economics, and the fact that R-22 has a lower price to their customers for outdoor and indoor equipment.

Pricing Realities Hit Home

Contractors and distributors realize that R-22 refrigerant is increasing in price, and report dramatic increases in the price of R-22 of 20 to 100% over the past two years. In addition, 44% reported they worry about the availability of R-22 refrigerant and parts for service after 2010.

Finally, 52% of survey respondents reported concern over how they’ll manage retrofit issues, including line set change-outs, equipment mismatches, and size differences of the new equipment.

Emerson Climate Technologies is surveying HVAC contractors and distributors to gauge their preparedness for the phase-out of HCFC refrigerants in new U.S. equipment by 2010. The 2010 phase-out marks a major undertaking for the HVAC industry.

For more information on R-410A readiness, visit www.EmersonClimate.com/refrigerant/ac.

| Carbon credits a peripheral issue for contractors We’ve all heard about carbon credits, but many may question what their implications are to the HVACR contractor. According to carboncycle.com, carbon credits are tradable permit bonds set with an assigned monetary value. They were devised to help implement a global cutback on emissions that affect the ozone layer. Each carbon credit gives the owner the right to emit one ton of greenhouse gas into the atmosphere. The monetary rewards of carbon credits are clear, in that participants are paid for reducing the amount of greenhouse emissions and pollutants their facilities emit into the atmosphere. The majority of carbon credit activity takes place at the manufacturer level. Sue Hall, director of The Climate Neutral Business Network, Oswego, OR, says emissions reduction must be based on practices that “go beyond business as usual,” which means it has to be some practice that is not done on a regular basis. “It has to be a new, progressive step,” Hall says. According to Hall, the bulk of greenhouse gas reduction for supermarkets or other retailers lies “upstream,” in the embedded carbon that comes into those stores. “Retailers, therefore, are focusing more intently on what their suppliers are doing from a climate perspective, and are encouraging their suppliers to measure and report greenhouse gas emissions in the Carbon Discosure Project (CDP),” Hall says. “The gases used in a refrigeration system are among the strongest global warming gases, in terms of their impact per unit/per pound,” Hall says. “Typically, when you’re dealing with gases of that intensity, they represent a spike for the people using them, such as contractors. Manufacturers and designers of refrigeration systems realize that the efficiency of their systems is a big factor. When they design systems that are far more efficient in terms of energy use, and other climate impacts, they have wondered whether those might qualify as beyond business as usual.” Residential and commercial HVAC contractors, builders, and building owners have the Leaders in Energy and Environmental Design (LEED) certification as the primary route to implementing energy efficient practices. If a refrigeration contractor believes he or she has taken unique and important steps to reduce carbon emissions, Hall says their activity must go beyond simply switching to newer refrigerants. “You have to be able to define what it is you’re doing differently, and why it’s beyond business as usual, what the barriers were which prevented others from doing it as well,” Hall says. “They would have to create a methodology, or performance baseline, by which you could evaluate the amount of carbon savings.” For more information on carbon credits, visit www.carboncycle.biz; www.carbonneutral.com; www.getcarboncreditco.com; www.cdproject.net. — Terry McIver, senior editor |