How to Find Duct Obstructions with a Manometer

One problem we all face sooner or later is solving the issue of a duct without airflow. The fan is on, the other registers have airflow, but for some reason, one room has little or no airflow. You’ve inspected for any obvious duct leakage, so by now, you’ve come to the conclusion there’s something in the duct blocking airflow. Let’s take a look at how you can “see” the duct obstruction and pinpoint its location, in just a few minutes, using an inexpensive manometer.

What’s in that Duct?

Restriction to airflow comes in all shapes, sizes and origins. Obvious airflow-killers include common causes such as interior duct liner hanging in the airstream due to missing pin-spotters and glue, and other interior duct damage. There may be left behind construction materials or an occasional misdirected rodent looking for a new tunnel or place to call home. Wayward teenagers often find that ducts are a safe place to hide magazines or other taboos-of-the-day from their parents as well.

Most of the time, low duct airflow is caused by some construction defect that may have been invisible to the original installer. An obstruction may be new damage caused by a cable guy crawling over or under a duct that unfortunately found itself in the path of a TV signal or the Internet.

Whatever the cause, our job is to pinpoint the location of the duct obstruction and remove it so the room can get the airflow it needs so comfort can be restored.

Tools Needed

The tools required to do this testing are not too expensive and are available across the industry. If you’re a service tech, installer or salesperson, you should have these tools or access to them already. A good quality manometer kit that will do the job will cost you less than $200. A manometer kit should contain the following:

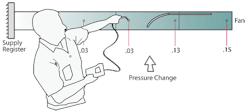

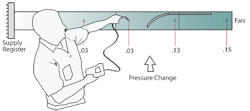

Example: The test holes in the duct as you move away from the fan may be: .15-in., .13-in., .10-in., .07-in. .05-in. and .03-in. As you can see, there’s no single point of significant pressure change. This steady decline in pressure usually indicates a poor quality installation throughout the entire length of the duct or undersized duct.

How to Repair Duct Blockage

If your testing reveals one point of significant pressure change along the length of the duct, you have a single blockage. Mark the spot, cut the duct open and remove the obstruction.

Repair the duct, assuring not to leave another obstruction to airflow. Seal the duct airtight. You may need to add additional strapping or support because the repair may have weakened the duct. If insulation was removed, be sure to apply adequate external insulation to the duct.

If there was not a single significant pressure change from one test hole to the next as described in the second example, you’ll have to evaluate installation conditions or duct sizing and make appropriate repairs.

Measure the airflow after the repairs are complete to verify adequate CFM and temperature are being delivered at the grille or register.

Enjoy the hunt.

Rob “Doc” Falke serves the industry as president of National Comfort Institute an HVAC based training company and membership organization. If you're an HVAC contractor or technician interested in a free Duct Obstruction Test Procedure, contact Doc at [email protected] or call him at 800-633-7058. Go to NCI’s website at nationalcomfortinstitute.com for free information, articles and downloads.

About the Author

Rob 'Doc' Falke

President

Rob “Doc” Falke serves the industry as president of National Comfort Institute an HVAC-based training company and membership organization. If you're an HVAC contractor or technician interested in a building pressure measurement procedure, contact Doc at [email protected] or call him at 800-633-7058. Go to NCI’s website at NationalComfortInstitute.com for free information, articles and downloads.