Service Clinic: Compressor Preventive Maintenance

During a preventative maintenance session or when working on a unit for other reasons, there are several things to check related to a compressor, in order to catch potential issues that may cause premature failure. It only takes a few minutes, and if done properly, can help ensure a compressor’s useful life. Remember, disconnect all power and check the volt meter. Be particularly cautious with the crank case heater (if present), as it may be connected to a different power source than the compressor.

1. General inspection of the compressor: Check compressor shell, piping connections and mounting. To start, check the compressor for discoloration on the head and by the discharge line. This can indicate that the compressor is experiencing excessively high discharge temperatures. If you see blistered paint or a brownish tinge, make note of it. Observe the mounting grommets and make sure they are not split or missing chunks. Ensure the fastening bolts are all present and not loose. On tandem compressor arrangements, make sure the assembly is mounted as per the manufacturer’s requirements or excessive vibration can occur. Look for oil around the piping connections and below the compressor, which can indicate a leak.

2. Electrical connections: Check the electrical connectors to ensure that they are tight with no free play. Loose connectors can cause poor voltage resulting in overheating of the connectors and motor. Look for discoloration of the terminals and conductor insulation, which will indicate overheating. If present, fix immediately. The electrical terminal box cover is very important, and if it is missing or cracked, replace it ASAP.

3. Winding and ground check: Over time, the compressor winding insulation can break down due to high temperatures caused by poor power supply quality or excessive operating temperatures. Check the resistance of the windings to make sure they are within the manufacturer’s specifications. Check the windings to ground to make sure that the winding insulation is good. If your meter is capable of reading into the millions of ohms and you can manage to obtain a value for resistance, check it against the specifications. If it is below this value, the winding insulation is beginning to fail.

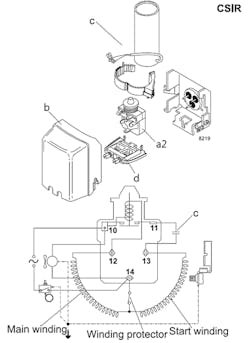

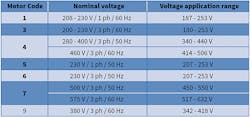

4. Relay and capacitors: It is important for the compressor to start quickly with no hesitation. Check the start relay and make sure it has clean contacts with no pitting. If it buzzes when energized, check the power connections and the voltage to the coil. If the voltage is poor, it can indicate a problem with the transformer or conductors. If everything checks out fine but the problem persists, replace the relay. On single phase compressors, make sure the capacitors have the correct capacitance rating. Never assume they do! Inspect the capacitor/s for cracking or leaking. If found, replace. Check the capacitance with a meter equipped with a capacitance check function. If the capacitor is weak, replace it.

5. Energize the system and check the voltage: The voltage should be within manufacturer’s specification. On 3-phase compressors, all three phases should fall within the voltage range. If it is not, then it needs to be corrected or the life expectancy of the compressor will be greatly reduced. Poor power supply kills more compressors than most people think. Check the running current once the system stabilizes after running for a few minutes. The current should be close to what is stated in the literature for the given pressures and temperatures of the evaporator and condenser. If not, check the

voltage at the compressor when it is running.

It is important for the compressor to start quickly with no hesitation ... If the capacitor is weak, replace it.

6. Liquid flood back and migration: Pay attention to the saturated suction superheat (SST). Manufacturers have a minimum recommended superheat level at the compressor suction inlet based on the saturated temperature of the refrigerant at this location. Always make sure the SST meets the minimum requirement for the temperature application of the system. Lower temperature systems can get away with lower SST values than higher temperature systems. The purpose of these values is to eliminate the return of liquid refrigerant to the compressor while it is operating which can dilute oil and result in bearing failures.

Off cycle migrations occurs when refrigerant vapor migrate to the compressor because it is colder than the rest of the system. The oil will absorb the refrigerant, which upon start up, boils out and causes the oil to foam, greatly reducing lubrication. Listen to the compressor on start up. If it makes a racket on startup and then quiets down, this is likely the culprit. The remedy here is simple: Install a crank case heater to keep the compressor oil sump warm.

7. Operating pressures and temperatures: Since the compressor is part of a larger system, operations in other areas impact compressor performance. Check the suction and discharge pressures and temperatures. The refrigerant charge, evaporator/condenser air flow and ambient conditions will all have an effect on these measurements. Any deviation from the expected values will indicate something is not right and it will need to be addressed. Loss of charge is responsible for a large number of failures and can be easily ascertained during this checkup. Look for a lower than normal suction pressure and high superheat. The expected values sometimes can be found in the manufacturer’s literature but often experience and understanding of how a system responds to these inputs is necessary.

8. Oil level check: If the compressor is equipped with oil sight glass, observe the oil level and monitor if and how it fluctuates during operation. As long as the oil remains visible within the sight glass, it should be fine. However, check the manufacturer’s specifications to be sure. If it fluctuates beyond the sight glass, it can indicate that large amounts of oil are leaving and may not be returning in a regular manner. If the oil is above the sight glass, it can indicate that the oil charge is excessive in the system.

I hope you enjoyed this column. There are certainly more checks I could have included but due to limited space I focused on the most prominent. I only bring one set of experiences to the table. Having more is a good thing, so please share your ideas and tips so we can all benefit with a little extra ‘on the job experience’ without having to get in the truck.

Jamie Kitchen is a trainer in the cooling segment of Danfoss.