Superheat and Subcooling: The Best Ways to Ensure Proper Refrigerant Charge

EDITOR'S NOTE: This article was updated to include photos and a tutorial video.

For many years residential air conditioners used pistons as metering devices, and you will still commonly encounter these systems. The piston looks like a small brass or bronze “bullet,” with a calibrated hole drilled through the center. The size of the hole, along with the pressure drop across the hole, determines how much refrigerant flows through the system.

Most of the systems with piston metering devices are charged by the suction superheat method. Manufacturers of these systems typically provide a charging chart or slide rule to properly charge their systems. Sometimes these charts are available from your wholesaler. If you’re fortunate, they may be included inside the service panel of the unit that you’re servicing.

Normally the charts will require an indoor wet bulb temperature reading as well as an outdoor dry bulb temperature reading. The indoor wet bulb reading reflects the total heat of the air and, therefore, the total loading on the indoor coil, both sensible and latent. The outdoor dry bulb temperature will affect how well the system can reject heat to the outdoor air. In the case of the outdoor air, there’s no latent heat involved. Once you determine the indoor wet bulb and outdoor dry bulb temperatures, check the manufacturer’s charging chart to determine the proper suction superheat.

To measure suction superheat:

1. Attach your gauge manifold to the suction service port on the outdoor unit. Do not use the common suction pressure port on a heat pump because the pressure drop through the reversing valve will affect the pressure reading.

2. Take the pressure reading and use a temperature-pressure chart to convert that reading to the saturated temperature of the refrigerant that the system uses. Note that most gauges have the commonly used refrigerants shown on the gauges. This is especially true of the newer digital gauges.

3. Next, attach an accurate digital thermometer to the suction line near the suction gauge port. It’s usually best to insulate the thermometer probe so that it’s not affected by the ambient air. The temperature that you measure should be warmer than the saturated refrigerant temperature. The difference between the saturated suction temperature and the measured suction line temperature is the suction superheat.

4. Add refrigerant to lower the suction superheat. Recover refrigerant to increase the suction superheat. Note that you should never add refrigerant if the superheat is already 5F or less, even if the charging chart shows 0°F. You don’t want to overcharge the system if your thermometer or gages are not perfectly accurate. Overcharging can damage the compressor and will also reduce both the capacity and efficiency of the system.

Note that if the suction superheat is correct and the suction pressure is low, the system probably has low airflow. Correct the airflow problem and check the charge again.

Measuring Subcooling

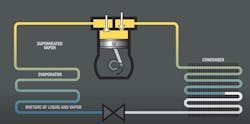

On many newer systems, especially high-efficiency systems, thermostatic expansion valves (TXVs) are used. Expansion valve systems are normally charged by using the subcooling method. Liquid sub-cooling is required so that you have only liquid entering the expansion valve with no bubbles present. Vapor bubbles present in the refrigerant will cause low refrigerant flow. Low refrigerant flow will cause a loss of capacity and efficiency in a cooling system.

Liquid sub-cooling is normally measured at the liquid line service valve. The manufacturer will usually specify the required sub-cooling on the outdoor unit service panel. It’s usually between 5°F and 15°F but always go by the manufacturer’s requirements.

WATCH THIS VIDEO FROM YELLOW JACKET FOR EXTRA TIPSTo measure liquid subcooling:

1. Attach your gauge manifold to the liquid line service port. If you use a quick-connect fitting on the end of your hose, make sure it’s a low-loss fitting. I’ve seen some quick-connect fittings that allow pressure loss, which can cause inaccuracies in the charging procedure.

2. Take a pressure reading. Use a temperature-pressure chart to convert the pressure to the saturated condensing temperature of the refrigerant.

3. Next, attach an accurate digital thermometer to the liquid line. It’s usually best to insulate the thermometer probe so that it’s not affected by the ambient air. The temperature that you read with the thermometer should be lower than the saturated condensing temperature. The difference between the measured liquid line temperature and the saturated condensing temperature is the liquid subcooling. Add refrigerant to increase subcooling. Recover refrigerant to reduce subcooling.

Note that if the subcooling and superheat are correct, and the suction pressure is low, the system probably has low airflow. Correct the airflow problem and check the charge again.

When charging by the subcooling method, you should be sure to check the suction superheat as well. If the expansion valve goes bad, you can have a very low suction superheat when you have the proper subcooling. In some cases, it’s not possible to achieve the required subcooling without having a superheat of zero degrees. If you get zero degrees superheat with a TXV, then the TXV is defective and will need to be replaced.

The Weigh-in Method

One other method of charging is the weigh-in method. The weigh-in method can be very accurate if you know the exact length of the refrigerant lines. The outdoor unit usually comes charged with enough refrigerant for the outdoor unit, a standard indoor unit, and 15 or 25 ft. of line set. You must add refrigerant for any line length over what is specified by the manufacturer. You may also have to add or remove refrigerant depending on what indoor unit or indoor coil is used. Even if you charge by weigh-in it’s still a good practice to check the charge using the subcooling or superheat methods, to ensure that everything is operating properly.

Kevin ONeill, CM, is the co-owner of O'Neill-Bagwell Cooling & Heating, Myrtle Beach, SC. He has 35 years of experience in the HVAC service business and is a 28-year member of the Refrigeration Service Engineers Society (RSES). Kevin can be reached at 843/385-2220, or by email at [email protected].