Some rules and regulations make sense, and others make no sense at all. Falling into the second basket is the Environmental Protection Agency’s proposed mandate against non-refillable refrigerant cylinders, those stalwarts that have served HVACR contractors so well for decades.

The EPA believes the AIM Act’s HFC refrigerant phase down gives it power to do whatever it thinks will somehow benefit the environment. It ruled that, beginning in 2023 and concluding in 2025, only refillable refrigerant cylinders may be used. And, it ruled that QR tracking codes must be applied to thousands and thousands of those new refillable cylinders, to be scanned at various points in their journey from factory, to distributor, to contractor and back again. It’s so bizarre, there has to be a lobbyist behind this.

ACCA, HARDI and other groups have petitioned the EPA and filed legal briefs to reverse this order. SEE THIS LINK.

During the recent ACCA Conference, a panel comprised of Avon, Ohio HVAC contractor Brian Stack, Wayne Powers, director of refrigerants for Worthington Industries, and Alex Ayers, government affairs director for HARDI, spoke on the major reasons why the ban is so impractical and anti-business.

Extreme Cost

“The new provisions require a four-to-one cylinder conversion rate, meaning for every single-use cylinder in the market today, there must be four refillable cylinders to replace it,” Powers explained, “to account for a cylinder at the filling line, another at the wholesale location another in the field with the service tech, and finally, one would be required at the refurbishing facility. With that, we’re talking about a price tag of about $2 billion. That’s an enormous cost this industry would have to bear.”

Your customers will bear the brunt of much of this cost, and lucky YOU, you get to explain it to them!

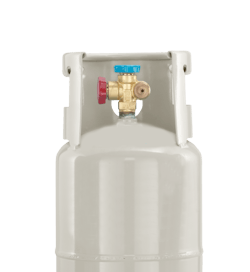

Non-refillable cylinders weigh from five to eight pounds when empty (tare weight). The tare weight of the refillable cylinders is about 21 pounds. Add 25 to 30 pounds of refrigerant, and the cylinder becomes much heavier than the weight OSHA recommends for worker safety.

Impedes, Endangers Technician Work

3D modeling evidence shared by the panel showed that fewer technicians can perform their jobs with a heavier, refillable cylinder. Based on the average size male, only 25 percent have the shoulder strength to unload a refillable cylinder; a mere 11 percent have the wrist strength to pull the cylinder to a roof; and only 25 percent have the shoulder strength to reload the cylinder to a higher position inside the service vehicle.

Powers said it was determined that the heavier cylinders would reduce the male workforce by as much as 75 percent, due to unrealistic working conditions. Brian Stack expressed concern for technician well-being and said truck retrofitting requirements will be required to make the heavier cylinders manageable inside a service vehicle. The cylinder ban would also put a severe strain on the supply chain that is struggling to keep up after the pandemic and with challenges brought on by the war in Ukraine.

“When we consider there is not enough capacity to produce the number of refillable cylinders that would be required to service the US domestic market and add to that the fact that [US] valve suppliers also do not have adequate or sufficient capacity to provide valves for these cylinders, we would be put in a situation where we’d have to purchase products from India, China and other foreign manufacturers. This is the exact opposite of what the AIM Act was intended to do,” Powers said.

Alex Ayers displayed a slide that showed more than 40 concerns HARDI members have with refillable cylinders, including many logistical challenges, increased shipping and handling costs, additional warehouse floor space, upgrading software and increased consumer cost.

“The AIM Act was specific in how it was designed to phase down HFC refrigerants. A cylinder ban or QR tracking code tracking system were never part of the legislation that the industry worked with Congress to write, and we were surprised,” Ayers said. “The QR tracking system is the worst idea ever.”

If you agree that the cylinder ban is a bad idea, register your complaint at www.stoptheepaban.com.

About the Author

Terry McIver

Content Director - CB

As director of content for Contracting Business, he produces daily content and feature articles for CB's 38,000 print subscribers and many more Internet visitors. He has written hundreds, if not two or three, pieces of news, features and contractor profile articles for CB's audience of quality HVACR contractors. He can also be found covering HVACR industry events or visiting with manufacturers and contractors. He also has significant experience in trade show planning.