HVAC Market Warms Up to Chilled Beams

You’ve learned a lot about radiant heat in the pages of Contracting Business.com, and now, as we trace radiant heating’s “genealogy,” we find a new member of the family has somewhat recently entered our consciousness: chilled beam radiant cooling.

With chilled beam systems, chilled water circulates through tubing embedded in a metal ceiling fixture to wick away heat.

What makes this technology so interesting is its broad applicability for commercial structures and extreme energy and thermal efficiency. A key advantage is that a chilled beam system requires very little ceiling space and height or, in the parlance of commercial architects and designers, it conserves interior real estate.

Another key advantage, functionally and financially, is that water — the main transporter of thermal energy, and much denser than air — permits very high energy carrying capacity and a smaller transport system: pipes.

Integration of Hydronics & Forced Air

Because chilled beams are ceiling-mounted and don’t use drain pans, the chilled water supply temperatures must be above the ambient dewpoint. As a result, dehumidification, or latent cooling, is handled by a separate 100% dedicated outdoor system (or DOAS) supplying dry, conditioned air to the space.

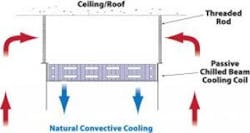

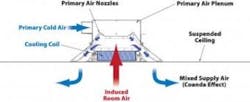

Passive chilled beams employ natural convection while active chilled beams employ forced convection. Passive chilled beam systems supply the DOAS airflow through a separate diffuser or grille in the room. An active chilled beam supplies the DOAS airflow through the chilled beam thereby increasing the capacity of the cooling coil through forced convection.

Chilled beam technology might sound futuristic, but trade professionals are surprised to learn that chilled beam technology is relatively simple and straight-forward.

The amount of outside air required to operate a typical chilled beam system is much less than that needed for a forced air system. A chilled beam system typically needs only one air change per hour, using outside air to pressurize the space to prevent the infiltration of outside air. With a forced air system, that need grows to 8 to 10 air changes of recirculated (and fresh) air to cool a space.

Chilled beams reduce the ceiling space typically required for the ductwork. The amount of air circulated by the central system is also dramatically reduced, often 80% to 90% less than with conventional, all-air systems. Of course, this also dramatically reduces the horsepower to circulate air within interior spaces. The net result is lower energy consumption and operating costs.

An Accessible Technology

Chilled beam technology might sound futuristic, but trade professionals are surprised to learn that chilled beam technology is relatively simple and straight-forward.

The chilled water temperature must be above dew point to prevent condensation from forming on the underside of the panels. This is typically in the range of 55F to 60F. The driving force or temperature difference between the chilled water and a room at 75F is therefore reduced, falling within the range of 15 to 20F as opposed to a conventional chilled water system using 40F to 45F chilled water and a range of 30F to 35F temperature difference.

As a result, higher chilled water flow rates are required to achieve reasonable capacities. The chilled water flow rate for chilled panels and ceilings is approximately double that of conventional chilled water systems.

Even with higher flow rates, the capacity of radiant chilled panels and ceilings is relatively low, in the range of 20 to 40 BTUH/sq. ft. While this is within the range of cooling loads for interior spaces, it may not be adequate for interior spaces with exterior walls.

Europeans discovered from their experience that by lowering the chilled panel below the ceiling that the convection cooling component of the individual panels could be increased; this satisfied the increased cooling loads from increased use of computers seen in the 1990s.

By lowering the panel below the ceiling and making it an open coil, as shown in Figure 1, the capacity of the chilled panel can be increased to approximately 120 to 150 BTUH/sq. ft. This configuration has been designated a “passive chilled beam” by the industry. It resembles a beam when mounted below the ceiling. It is passive since the convective cooling component is natural convection.

Active chilled beam capacities are in the range of 350 to 600 BTUH/sq. ft. for the coil. Added to this is the capacity of the primary air from the DOAS. Depending on the temperature and quantity of this primary supply air, this can add up to 300 btuh/sq. ft. of capacity. An active chilled beam can deliver from 500 to 900 btuh/sq. ft. between the chilled coil and the primary air (see a chilled beam configuration in Figure 2).

Primary/ventilation air is introduced into the active chilled beam through a series of nozzles. This induces room air into the chilled beam and, in turn, through a water coil. Induced room air is cooled and/or heated by the water coil, then mixed with ventilation air and released, controlling room temperature. As more systems are installed here in the U.S., chilled beam technology has developed into an alternative to conventional variable air volume (VAV) systems.

Injection Mixing Systems

Although radiant cooling and chilled beams reduce fan electrical energy demand and consumption up to 10 times from an all-air HVAC system, the pump energy demand doubles. If the pump energy could be reduced, then a radiant cooling/chilled beam system could achieve significant energy savings.

Taco’s LOFlo injection mixing system accomplishes this. Injection pumping has been used for a number of years in radiant heating systems by mixing-down the higher temperature boiler water (at 180F) to that needed for a radiant floor panel (100F to 120F). This same principal can be applied to a radiant cooling system, only in reverse – to mix-up low temperature chilled water (40F to 45F) to that required by a chilled ceiling panel or beam (55F to 60F).

The LOFlo system reduces the electrical energy demand of an all air system by almost 30% or more, thus reducing the transport energy to only 20% of the total HVAC system. The unit is a prepackaged system consisting of a variable speed injection circulator and constant-speed zone circulator. The variable speed injection circulator is controlled by a sensor that monitors incoming water temperature to a radiant panel (floor, wall, or ceiling) or chilled beam (ceiling). The constant-speed zone circulator is controlled by the room thermostat.

Greg Cuniff, PE is application engineering manager for Taco, Inc. taco-hvac.com