AHRI/BOMA Panel Addresses Commercial IAQ

A panel of indoor air quality experts recently participated in “Indoor Air Quality in Commercial Spaces,” a webinar presented by Air Conditioning, Heating and Refrigeration Institute (AHRI) and the Building Owners and Managers Association International (BOMA).

Webinar moderators were Francis Dietz, vice president, public affairs, AHRI; and Don Davis, vice president, advocacy and codes, BOMA International. Topics were Basic Codes and Standards; Physical Characteristics of Organisms; and Air Cleaning Device Dos and Don'ts.

Ernest Conrad, PE, LEED AP and principle of Ernest Conrad Consulting, shared information on applicable codes and standards; the physical characteristics of various target organisms; particulate filtration mechanisms; and various approaches for particulate control.

As a CEM, Conrad is qualified for performing energy audits and designing and implementing improvements, including commercial residences and historically significant structures.

CLICK TO WATCH THE ENTIRE WEBINAR

"ASHRAE 62.1 is intended to improve indoor air quality by mandating a minimum amount of outdoor air into a building. That minimum is either 5 cfm per person; or it has another method which is called the ‘ventilation rate procedure,’ which is based on dilution ventilation and treatment of other indoor pollutants," Conrad explained. "ASHRAE Standard 55 is theoretical human comfort chart. As you can see, if you’re a person who is in the environment between about 70-80 degree Fahrenheit and 30-50% RH, you are by definition ‘a comfortable person’. And a big part of indoor air quality is in fact to have human comfort."

Conrad reviewed the size of the most common indoor particulates, and the difficulties in capturing virus particles.

"Hair is 100 microns in diameter. Tobacco smoke ranges between .01 to about 10 microns in size. The particle size of a virus ranges from .003 to about .03 microns. A virus particle is 30,000 times smaller than a particle size of tobacco smoke. If you think of tobacco smoke as a tiny tiny particle that lays in the air, a virus is 30,000 times smaller than that. This is why it’s so difficult to deal with viruses, because the sized of the particle is so incredibly small.

"Bacteria ranges between .3 to about 30 microns in size. And these particles are larger than tobacco smoke, but at the same time they need a surface to attach to. So you will find them attaching to water droplets or to other types of organic materials."

"The Center for Disease Control says the MERV 13 filter is the standard for virus control. All of us are now targeting a MERV 13 rating, which gives you a filtration rating of about 90 percent of particle sizes smaller than about one micron," Conrad said. The other filtration benchmark is the highest level, which incorporates the use of MERV 17 HEPA filters. "These are the filters that will capture 99.97 percent of particles smaller than .1 micron in size," Conrad said.

Conrad presented a filtration effectiveness table. "Some years ago we used to have particle efficiency ratings on air filters and used what was called the dust spot method. We don’t anymore, but it said the typical, one-inch throwaway HVAC filter is about 30 percent efficient. Today that is equivalent to a MERV 8. MERV stands for “Mean Efficiency Rating Value”.

Conrad said a modern, Class A office buildings has filtration efficiencies between 60 and 80 percent, using the dust spot method.

"That 60 percent is about a MERV 11. In New York City, there is a law that says the minimum amount of filtration has to be MERV 11. So all of New York City office buildings have a minimum air filtration rate of MERV 11, which is about 60-65 percent efficient. In the other more modern office buildings, we use efficiencies of about 80 to 85 percent, which is equivalent to a MERV 13. The CDC says the MERV 13 filter is the standard for virus control. All of us are now targeting a MERV 13 rating, which gives you a filtration rating of about 90 percent of particle sizes smaller than about one micron."

High efficiency MERV 17 HEPA filters will capture 99.97 percent of particles smaller than .1 micron in size.

Conrad suggested five simple practices to control particulates in buildings:

Guy Tomberlin, vice president of plumbing, mechanical and gas programs with the International Code Council, emphasized that there is no single solution for all buildings.

"We have offices, schools, restaurants, fast-food establishments, and older buildings. So many different environments require different IAQ solutions. There will be a different ‘new normal’ for your customers’ particular building. Some may want to replace, upgrade and/or retrofit systems. Some may already have state of the art equipment, and your focus will be on maintenance and operations. And others may find that changing system components is more challenging than originally expected."

Tomberlin explained how Indoor Air Quality is indoor air quality is based on individual specific applications, including:

- Type of structure

- Type of occupancy

- The existing equipment

- The needs of the occupants

- The ability to alter equipment and practices.

Structural differences and purposes of building types are evident.

"Stores, restaurants, multi-purpose facilities, or fire stations, each have multiple areas that have to be maintained in different ways. A store has a different need than a restaurant. In a fire station, the bays where the vehicles are parked are exposed to diesel fuel fumes. Then the ambulances typically carry have medicines that are temperature sensitive. The fire station also houses sleeping quarters an office space and perhaps a workout area. All different, in one facilitiy. How you deal with each area’s IAQ will be different," Tomberlin explained, and could possibly result in the need for multiple pieces of IAQ technology.

Stores, restaurants, multi-purpose facilities, or fire stations, each have multiple areas that have to be maintained in different ways.

“The ‘new normal’ for IAQ may be different for everyone," Tomberlin said. "There will be a different ‘new normal’ for your customers’ particular building. Some may want to replace, upgrade and/or retrofit systems. Some may already have state of the art equipment, and your focus will be on maintenance and operations. And others may find that changing system components is more challenging than originally expected."

The point is, make sure you look at these systems holistically.

Tomberlin outlined the three basic mechanical codes published by the International code Council:

1. International Mechanical Code for new construction, design, engineering and installation of HVAC mechanical systems.

"ASHRAE 62 is important because the outdoor air requirements are clearly outlined in the IMC, for different types of occupancies, along with square footage and the efficiency of the system. That’s how all of these outside air calculations are performed. So all of this has to be taken into consideration to determine the best and most efficient IAQ for a particular space. Also, an air balance is required."

"The original permitting information, if an area adopts international codes, can help, if it's available. That’s where you can begin your evaluation. Does the building have an older system designed to do one thing, or a newer design that is designed to do another. It’s critically important if you’re undertaking a large rehabilitation project?" he said.

2. The Existing Building Code, which may or may not be in-sync with today's requirements.

"Some people think, 'we have a 5-year old building, it meets the current code requirements, so everything’s fine. We have the best and latest greatest equipment, so we don’t have to make any adjustments, but that’s not entirely accurate," Tomberlin cautioned. "That equipment could have been installed under two or three previous code editions. We have now published the 2021 codes. The codes are published every three years. You could see some changes from your building design for as recently as three years ago. And more importantly, some of the designs for buildings from the early 1990s could have had outdoor air ventilation that incorporated cigarette smoking activities, which changed things as well. Those designs came from ASHRAE 62, and that has changed tremendously from the late 1980s editions to now, where smoking is not a general concept in a building. You might also have the same tenants in the building, but they might have moved around.

"For example, today’s conference rooms require more airflow and more outside air. If the tenant replaced two office spaces with a conference room, if might have had much less airflow coming through that space when it was designed for two offices, and not updated the requirements for the new use of the space."

3. International Property Maintenance Code. This code requires that all mechanical equipment is maintained in a safe working condition and shall be capable of performing the intended function.

"This code requires that all mechanical equipment is maintained in a safe working condition and shall be capable of performing the intended function," Tomberlin explained. "Duct systems shall be maintained free of obstructions and be capable of performing the required function.

“This basically says you must have a system that is operating safely and can perform its intended function. Remember that building codes are written on minimums, not maximums. So now, if you’ve found the original blueprints and drawings, and you might find out that it’s a great system that works perfectly and meets the current code requirements for the health, safety and welfare of occupants and visitors, but it could be improved. So you might want to make enhancements."

"Fully evaluate your specific IAQ needs as a holistic system working together within a structure's space." - Rod Tomberlin

Tomberlin stressed the importance of a holistic approach to building alterations. "Fully evaluate your specific IAQ needs as a holistic system working together within a structure's space. Determine what actions you intend to undertake, and determine which codes and standards are applicable, and check with the Authority Having Jurisdiction to determine permitting and plan submission needs. Then, commission and air balance the final product," Tomberlin said.

Presenter Ron Cosby, technology and thermal systems leader, Americas Commercial HVAC of TRANE Technologies, said building owners and managers must ensure the building systems are working together, to achieve the desired outcome for risk reduction from an IAQ perspective.

"You also want this to be an ongoing process that can lead to an overall high quality building environment," Cosby said, and then, outlined the three IAQ tenets of "Assess, Mitigate and Manage." Cosby told the webinar audience of the importance of assessing a building's current indoor air quality capabilities as the first step in "regaining trust" in a building.

"Figure out where your building is today, with a fact-based, data-driven analysis of your building’s indoor air quality. If you don’t know where your building is today, you can’t strategize on where you want it to go. The assessment helps you establish a baseline and develop a plan to mitigate any indoor air quality issues."

This is done with the Four Pillars of IAQ

1. Dilute: make sure plenty of fresh outdoor air dilutes the buildup of indoor contaminants through proper ventilation. A Dedicated Outdoor Air System is a great mitigation technology that falls within this category. There are other numerous items that the CDC and ASHRAE have identified as dilution solutions.

2. Exhaust: Getting exhaust air out of difficult areas is equally important, especially air from kitchens restrooms, and combustion systems. “You might want to keep fans on 100 percent of the time kitchens, restrooms, and other areas.”

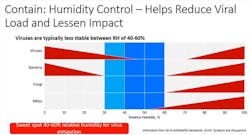

3. Contain: Keeping indoor humidity levels within the ASHRAE recommended range maximizes occupant comfort and reduces the risk of microbial growth. To illustrate the value of humidity against COVID, Cosby shared research from the Department of Homeland Security that shows increasing humidity results in a less active viral count. SARS-Cov-2 will naturally deactivate at higher humidity levels, and help to reduce the need for other abatements. The ideal RH for this is between4. Clean means attacking these contaminants. Reduce particles, odors or micro-organisms such a mold, bacteria and viruses.

Cosby said controls platforms are evolving to meet a future focus on IAQ. These include:

- Standalone, in-room, or building-wide control and communication/dashboard options.

- Analyzing air quality trends and source potential problems.

- Tracking improvements over time.

- Meeting performance requirements set by WELL, RESET or your own team.

- Engage stakeholders with visual demonstration of results.

- Optimize comfort and IAQ for balancing risk mitigation with energy consumption.

Cosby then shared a review of cleaning technology conducted over the past year by TRANE Technologies, at a third-party testing laboratory. Technologies were tested for in-duct/in equipment and in-room (stand-alone) scenarios.

Four technologies were tested and compared for their respective virus reduction capability, bacteria reduction capability, VOC reduction capability of formaldehyde and toluene, and ozone generation.

VISIT THE YOUTUBE VIDEO TO HEAR THE RESULTS OF the testing.