How UV-C Has Become a Health and Safety Necessity

Many HVACR engineers are familiar with the restorative abilities of nature’s own antiseptic—Ultraviolet Germicidal Irradiation (UVGI or UV‑C) energy—to remove biological growth from HVAC coils and return cooling capacities to original design specifications.

The same bacterial growth that robs HVAC systems of heat-transfer efficiency also harbors infectious pathogens that can be broadcast to building occupants through conditioned airstreams.

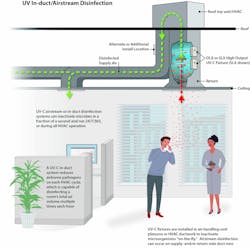

The COVID‑19 pandemic has helped to highlight the germ-killing or germicidal aspect of UV‑C in both 1) HVAC in-duct, or airstream disinfection, and 2) upper‑room decontamination applications. A quick primer on both technologies:

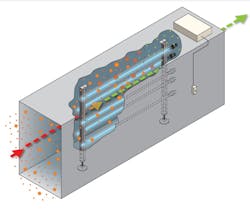

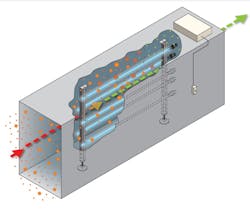

HVAC airstream-disinfection systems*

As seen in Figures 1 and 2, UV‑C airstream or in‑duct disinfection fixtures are installed in air handling unit plenums or HVAC ductwork to inactivate microorganisms “on-the-fly.” A UV‑C in-duct system can disinfect a room’s total air volume multiple times each hour as the air recirculates through the HVAC system.HVAC UVGI systems are commonly designed for a minimum of 0.25 seconds of UV‑C exposure or “residence” time. The faster the air is moving, the higher the UV‑C output (dosage) must be to achieve the desired inactivation rate.

Upper-Room/Air systems

Wall-mounted seven-feet and higher, upper-room UV‑C fixtures generate a germicidal zone near a room’s ceiling where infectious pathogens are quickly neutralized. The natural rise-and-fall of convection or mechanical air currents lift pathogens overhead where they are inactivated in a matter of seconds. (See Figure 3).Upper-room UV‑C fixtures can provide a space with the equivalent of up to 10 air changes per hour (ACH), which helps to augment other building ventilation and dilution strategies. And since UV‑C energy is overhead, upper‑room fixtures areHow UVGI Works

Through a process known as photodimerization, the UV‑C wavelength uses electromagnetic energy to destroy a microbe’s nucleic acids. This cellular damage prevents microorganisms from infecting and reproducing.In general, the effectiveness of UV‑C air disinfection boils down to time and intensity, (i.e., how much time/duration a pathogen is exposed to the UV‑C energy will determine how much germicidal intensity is required.). In other words, higher velocity airstreams require greater intensity because of the limited residence time.

There are operational conditions that factor into this equation including the target pathogen and its susceptibility to UV‑C; the amount of airflow (volume and velocity); the air temperature and relative humidity; the length of exposure time (duct length); and the duct material reflectivity. Each of these variables factor into the amount of UV‑C energy necessary in any given application (installations can be modeled to help predict individual dosage levels).

Disinfecting Airstreams with UV-C

In April 2021, the CDC1 acknowledged that COVID‑19 is primarily communicated through airborne and not surface transmission. The ASHRAE Epidemic Task ForceMoreover, because of the asymptomatic nature of this and other diseases, people can spread COVID‑19 before anyone knows they are contagious.

ASHRAE and Filtration

Since the pandemic began, many of the HVAC-oriented infection mitigation strategies have focused on the use of high-efficiency filters. ASHRAE recommends using an HVAC filter with a MERV (Minimum Efficiency Reporting Value) rating of 133 but cautions that not all AHU systems are designed to operate with this filter efficiency level and the corresponding pressure drop.Some HVAC professionals are avoiding this conundrum using a layered approach, that is combining UV‑C with filters to yield higher efficiency rates without sacrificing airflow levels. In his book, “Ultraviolet Germicidal Irradiation Handbook,” Wladyslaw Kowalski demonstrates that combined filtration and UVGI can boost the MERV 13 filter removal rate of MRSA (Staphylococcus aureus) from 85 percent to 99.9 percent. "UV and filtration will provide optimum air cleaning if the components are sized properly," he writes.

Said differently, marrying UV‑C fixtures with filtration can increase the overall system’s “removal rate” as the filtration captures the larger pathogens, and the UV‑C can deactivate the smaller, more susceptible pathogens.Overcoming Supply Challenges

Before COVID-19, the UV‑C market had seen continued growth, largely based on the germicidal wavelength’s ability to improve HVAC energy efficiency and to reduceAs a result, UV lamp manufacturers, as well as their component suppliers (e.g. glass suppliers), struggled to scale from what was a niche marketplace to mass production capable of meeting historic interest levels.

Given the current environment, industry insiders recommend contractors and end-users (e.g. schools, etc.) place UV equipment orders as early as possible and to accept partial-order shipments allow them to begin the installation process.

CONCLUSION

Given the increased focus on infection mitigation, HVAC contractors and facility professionals can utilize germicidal ultraviolet technologies to greatly reduce concentrations of pathogens in a highly reliable and cost-effective fashion.

Today, the market is starting to view UV‑C along the same lines as air filtration. Just as no one would operate an HVAC system without air filters—the time is near when no one will operate HVACR systems without UV‑C installed.

*All references to “disinfection” are referring generally to the UV‑C germicidal inactivation of pathogenic biomass through the process of photodimerization and are not intended to refer to any specific definition by the U.S. Food and Drug Administration or the U.S. Environmental Protection Agency.

________________________________________________________________

DANIEL JONES is president, UV Resources, Santa Clarita, Calif.

1 CDC. Science Brief: SARS-CoV-2 and Surface (Fomite) Transmission for Indoor Community Environments. April 5, 2021. Retrieved from https://www.cdc.gov/coronavirus/2019-ncov/more/science-and-research/surface-transmission.html

2 ASHRAE. ASHRAE Epidemic Task Force Releases Updated Airborne Transmission Guidance. Press Release. Retrieved from https://www.ashrae.org/about/news/2021/ashrae-epidemic-task-force-releases-updated-airborne-transmission-guidance

3 ASHRAE. ASHRAE Technical Resources; Filtration and Disinfection FAQ. Retrieved from https://www.ashrae.org/technical-resources/filtration-and-disinfection-faq

SEE SIDEBAR BELOW

ABOUT THE TECHNOLOGY (See Figure 6)

The RLM Xtreme fixtureless UV-C lamp system from UV Resources generates up to twice the ultraviolet irradiation levels as fixtured lamp systems, making it one of the most effective germicidal irradiation solutions available today.

With the industry’s highest UV-C fluence (dosage) and flexible mounting options, the near-universal applicability of the RLM Xtreme is ideal for high-volume airstream/induct disinfection or coil irradiation treatments. Designed for both new and retrofit applications, the RLM Xtreme is independently verified to meet UL-2998 zero-Ozone standards.