Webinar: Optimize Displacement Ventilation with CFD

SimScale will host a 30-minute webinar on December 19th, to show how to use cloud-based engineering simulation to virtually test and optimize ventilation systems.

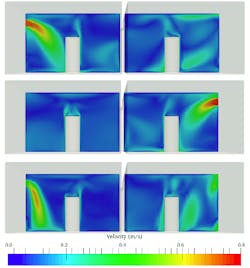

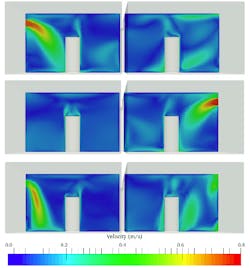

During this exclusive webinar, SimScale’s CEO David Heiny will use Computational Fluid Dynamics (CFD) models to evaluate the air conditioning performance in a partitioned room using two different ventilation systems: mixing ventilation and displacement ventilation.

In contrast to mixing ventilation, a displacement ventilation system is an air distribution strategy that introduces conditioned outdoor air at a low velocity from air supply diffusers usually located near floor level.

With this system, the cool air accelerates because of the buoyancy force, pooling near the floor level, and is then carried up into the thermal plumes that are formed by heat sources. This type of air distribution strategy can effectively deliver fresh air to occupants and remove the contaminants, creating a comfortable and healthy environment as a result.

Each approach has its strengths and weaknesses, however, and the right strategy needs to consider a variety of factors. Supplying air from diffusers located near floor level, for example, has significant design implications. The air must be supplied at higher temperatures and lower velocity in order to avoid uncomfortable drafts. This implies that the air diffusers need to be much larger than those of other ventilation systems. At the same time, delivering air at a lower velocity allows fans to run more slowly, lowering the energy consumption.

All factors need to be taken into consideration and the concept and design stages are the ones in which the most significant changes and improvements can be made. Afterward, the costs for every modification comes with a high cost.

Engineering simulation is one of the tools that play a fundamental role in those early product development stages, allowing engineers to make more informed design decisions earlier in the process. For the final product, this can mean lower production costs, more efficient energy consumption, lower failure risk, and more.

To sign up for this free webinar — Displacement Ventilation Design with CFD — CLICK HERE