Cost and Air Quality Benefits of Enhanced Ventilation Systems

Among the lessons learned during the pandemic is this big one: We no longer can look at building ventilation systems from just a pure comfort standpoint. Comfort has been replaced by health and safety as top priorities.

Of course, many of us who design, build, install and operate building ventilation equipment have long been concerned with proper filtration to achieve air quality. However, recommendations for appropriate levels of filtration may not have been fully implemented. And the new risks associated with COVID-19 compel us to change our priorities. For many property owners, there’s urgency to significantly improve air quality within buildings — especially as businesses, schools and other organizations seek to fully reopen their facilities.

COVID-19 Increases Air Quality Awareness

A host of airborne viruses and bacteria can spread throughout building ventilation systems and cause illness, according to the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE).1 Proper air flow, air changes and filtration of facility air have become more important than ever.

Research shows improved ventilation reduces exposure of building occupants to SARS-CoV-2, the coronavirus responsible for COVID-19. In addition, better ventilation reduces exposure to influenza, rhinovirus and mycobacterium tuberculosis. This understanding led industry groups and government agencies — including ASHRAE along with the U.S. Centers for Disease Control (CDC) and the U.S. Environmental Protection Agency (EPA) — to recommend:

- Operating ventilation equipment 24/7 if possible, or at least two hours before occupants arrive

- Running nights and weekends, at least on a low setting

- Switching air handling units with recirculation to 100 percent outside air when weather conditions permit, and

- Keeping ventilation on in restrooms 24/72

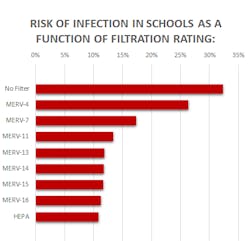

Benefits of MERV-13 Filtration

Upgrading filtration to a minimum level of MERV-13 or better also is recommended by ASHRAE, the CDC and EPA as well as Regal. MERV stands for “minimum efficiency reporting value”; the higher the rating, the more particulates as well as viruses and bacteria that can be filtered in a building’s air handling system.3

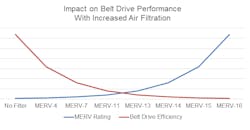

Impact on Ventilation System Components

It’s important to note that improving MERV levels increases resistance on the belt drive that transmits power from a motor to a ventilation fan. Belt drive efficiency diminishes as resistance increases. Causes of performance decay can include:

- Belt drive tension

- Belt type (wrapped vs. notched)

- Sheave wear

- Poor alignment.

Belt Drive Startup Best Practices

Due to COVID-19, many individuals are working from home, so most commercial buildings have either been closed down or are operating with a limited number of occupants. As a result, the HVAC systems in these buildings are likely operating on a reduced schedule, or may have been turned off completely.

If the HVAC systems are not running for a long period and then are turned back on, the equipment can be stressed to the point of failure. To minimize that risk, here are our recommendations for starting up belt drives after an extended shutdown:

- Check belts for any signs of wear or damage (cracks, sidewall wear, other visible damage). If present, change the belts. If the belts haven’t rotated and have been under tension for an extended period of time, change them.

- Check the sheaves for rust and wear; rust can cause the belts to corrode. If any is present, change the sheaves.

- Check belt tension and drive alignment (use tension checker and straight edge or string) for best performance and drive life.

- If you have had difficulty releasing belt tension due to a seized or broken motor base, consider changing the motor base.

Five Steps to Belt Drive Efficiency

As you prepare to return building ventilation systems to regular operation, the following low-cost solutions can help you to meet new air exchange requirements.1. Upgrade to Notched Belts

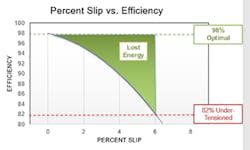

Raw edge notched (cogged) V-belts such as the Browning® TorqTitan™ Notched Belt can transmit more horsepower than standard wrapped belts (98 percent compared to 95 percent), which contributes to energy cost savings. In addition, raw edge notched V-belts provide a higher coefficient of friction (COF) with the sheave groove wall, which creates less slip when properly tensioned.2. Properly Tension Belts

Inadequate tension on V-belts causes them to slip, which results in efficiency and energy loss (see graph below). Causes of under-tensioning include:- Belts that have been "rolled onto" the sheaves

- Replacing belts and moving the motor base back to a “preset mark”

- Worn sheaves.

Installing V-belts with the manufacturer’s recommended tension is the first step. Regularly checking and readjusting the tension are critical. It’s surprising how many building operators install V-belts but never check them until they fail. Belts should be inspected and adjusted following the manufacturer’s schedule.

3. Replace Worn Sheeves

Ventilation systems can lose as much as 8 percent of their efficiency because of worn grooves on sheaves (pulley wheels). Uneven wear on multiple groove sheaves can create unequal load sharing across all V-belts, which causes belts to slip, excess friction and heat, resulting in premature failure. And smaller sheaves — usually the motor sheaves — wear out faster.

To avoid reduced air flow from the blower unit, replace any sheave groove worn greater than 1/32 inch.4. Install Self-adjusting Motor Bases

Building operators can gain 1.5 percent in efficiency by using a continuously adjustable motor base such as the Browning Tenso-Set® Self-Adjustable Motor Base. Other benefits include:

- Decrease time needed to change belts; more with a quick-release version

- Maintain consistent tension throughout life of belt

- Longer belt life

- Increases and maintains V-belt drive efficiency

- Maintains drive alignment, which reduces the time to align the ventilation drive during installation and helps to increase belt life

- Saves 1.4 percent of energy costs with a return on investment (ROI) in two years.

5. Upgrade to Premium Efficient Motors

In the United States, most ventilation system motors were installed in the 1980s. Although they may still operate, replacing them with modern, premium efficient motors can improve their efficiency by 4.8 percent.

Taking the Next Steps Toward Reopening Buildings

Improving air flow and filtration as part of HVAC systems can be one of the most effective ways to minimize the spread of the coronavirus that causes COVID-19 as well as other viruses and bacteria that can cause health issues for building occupants and visitors.

Worn V-belts and sheaves or improperly tensioned belts reduce ventilation system efficiency and increase energy costs. They also can lead to equipment failure and unplanned downtime. What’s more, well-designed and maintained belts and sheaves can positively impact all the other components and overall ventilation system efficiency.

As more organizations prepare to reopen buildings, they can enhance health and safety by inspecting ventilation equipment and following best practices to replace and/or upgrade V-belts, sheaves and motor mounts.

About the author: In his role as the director of marketing for Regal Beloit Canada, Jesse Dupuis specializes in electrical/mechanical HVAC systems with a focus on V-belt driven technology. He is well-versed in system optimization, proper installation techniques and component selection best practices.

About the Author

Jesse Dupuis

Director of marketing, Regal Beloit Canada

In his role as the director of marketing for Regal Beloit Canada, Jesse specializes in electrical/mechanical HVAC systems with a focus on V-belt driven technology. He is well-versed in system optimization, proper installation techniques and component selection best practices.

Throughout his career, Jesse has worked with commercial and industrial institutions across North America, has collaborated with government agencies on efficiency and energy rebate programs, and has presented at several HVAC industry association shows.

Jesse earned a bachelor’s degree in mechanical engineering from the University of Western Ontario.