Why Some Supply Registers Act Like Return Grilles

It may sound ridiculous, but supply registers can act like return grilles in some installations. It’s likely you’ve encountered this situation but overlooked it. Let’s look at the field conditions necessary for this problem, why it happens, and a simple solution to this confusing installation defect.

Pay Attention to Attic Duct Systems

Typically, supply registers act as return grilles on attic duct systems. These installations often have a supply plenum with a large duct coming off the end cap and smaller branch ducts from the plenum feeding interior rooms such as bathrooms, utility rooms, and closets.

I first experienced this issue on a horizontal air handler in an attic with a four-foot supply plenum attached to it. The installation used a short, five-inch flex duct for an interior powder room underneath the air handler. A 16-inch flex duct was coming out of the plenum’s end cap to feed a remote plenum about 25 feet away.

The first cause involves the location of the smaller branch takeoff. The second is excessive air velocity moving past the smaller branch takeoff opening.

Usually, I wouldn’t pay any attention to this installation because it was so common. However, I noticed condensation dripping from the supply register. I inspected the register and heard air noise but felt no air blowing out of it. In fact, the air was being sucked in.

What Causes a Supply Register to Act Like a Return Grille?

If your first reaction is that there’s no way supply airflow and return airflow can exist in the same duct system, you’re right. So, something else is causing this to happen. Two causes can contribute to this situation.

The first cause involves the location of the smaller branch takeoff. In this case, it was mounted near the air handler discharge, with a much larger duct downstream. The second was excessive air velocity moving past the smaller branch takeoff opening.

Because large amounts of air move past the smaller branch takeoff to feed larger ducts downstream, the air never turns into the smaller duct. Instead, it quickly bypasses the smaller opening creating a suction effect. Our industry often refers to this phenomenon as the Venturi effect.

Look For the Indicators

You rarely hear of comfort issues because of this duct defect. That’s because usually, the rooms that suffer from this problem are interior rooms, and heating or cooling provided by other supply registers conceals the issue. You may also discover the following:

- Higher than expected humidity in problematic rooms

- Condensation and dirt on the face of the register

- Unwanted odors coming from the supply ducts

- Noise from the register, but no air velocity coming out of it.

Here is one simple test to discover this condition. Hold a sheet of single-ply toilet paper against the supply register. If the problem exists, the toilet paper will hold in place instead of blowing away. You can even trace the air back to the supply plenum and disconnect the duct from the branch takeoff. If you hold your hand up to the opening, you will likely feel air rushing past it instead of blowing out.

Preventing and Correcting the Airflow Reversal

The first step to prevent this issue is to pay attention to where you install supply branch takeoffs. Make sure there are no substantially larger runs downstream that can contribute to the Venturi effect. In this scenario, simply attaching a branch duct to the supply duct system doesn’t necessarily mean air will blow out.

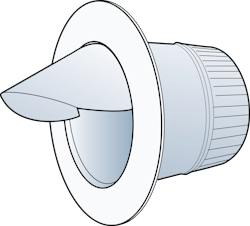

In retrofit situations, you won’t have the option to reposition supply branch ducts. If that’s the case, you can use a scoop takeoff on the problem duct to direct airflow from the plenum into the branch duct.

Remember, the blower creates pressure change in the duct system to move airflow. If the duct installation or design places smaller ducts near the air handler discharge, the pressure change inside the supply duct system can cause airflow reversal. In some installations, you may need to move smaller branch takeoffs further downstream so the air in the supply duct doesn’t bypass them.

In retrofit situations, you won’t have the option to reposition supply branch ducts. If that’s the case, you can use a scoop takeoff on the problem duct to direct airflow from the plenum into the branch duct. While not ideal, this solution has saved me many times and is how I fixed the original problem. However, ensure you don’t use too many scoop takeoffs in a row. One is fine, but more than that can disrupt airflow downstream and cause even more problems.

Take a closer look at your installations and make sure you aren’t unintentionally designing and installing supplies that act like returns. This problem can be difficult to diagnose unless you know what to look for. But with the proper knowledge and understanding of duct design, you can prevent this shortcoming in your duct systems.

David Richardson serves the HVAC industry as Director of Training for National Comfort Institute, Inc. (NCI). NCI specializes in training to improve, measure, and verify HVAC and Building Performance.

If you’re an HVAC contractor or technician interested in learning about how to add air diagnostics to your services, contact David at ncilink.com/ContactMe. NCI’s website, www.nationalcomfortinstitute.com, is full of free information to help you improve your professionalism and strengthen your company.

About the Author

David Richardson

Director, technical curriculum

David Richardson serves the HVAC industry as director of technical curriculum at National Comfort Institute, Inc. (NCI), Avon, Ohio. NCI specializes in training that focuses on improving, measuring, and verifying HVAC and Building Performance.