UV-C Monitoring Helps Ensure HVAC Efficiency and Energy Savings

Ultraviolet light has been used since the 1990s to enhance HVAC efficiency, improve air quality, and reduce energy consumption. Germicidal UV technology has attracted attention since researchers demonstrated that UV‑C can reduce airborne pathogens in occupied spaces. In 1937, epidemiologist William F. Wells installed UV lamps in Philadelphia schools and lowered measles infection rates to 14.5% compared to 55.3% in schools without UV‑C.

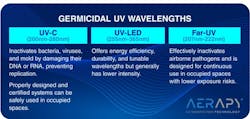

Today, the focus continues to evolve. This article delves into the mechanics of germicidal wavelengths — specifically traditional UV-C (254 nm), UV-C LEDs, and the emerging Far-UV (222 nm) — and how these tools impact HVAC performance. It also explores the critical importance of timely UV lamp replacement and ongoing wavelength intensity monitoring to ensure consistent disinfection performance and optimal system operation.

Understanding UV-C in HVAC Systems

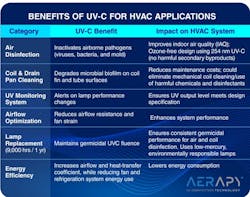

UV‑C, or energy in the C-band of the UV spectrum (200–280 nm), is the most widely used and extensively studied wavelength range for germicidal applications. Ideal for penetrating and disrupting the DNA or RNA genetic code of viral, bacterial, and fungal organisms, UV‑C energy prevents microbes and pathogens from replicating, thus reducing their spread.

During the 1940s, many hospitals began utilizing UV‑C energy to destroy airborne and surface-bound microbes, including chickenpox, measles, mumps, tuberculosis, and cold viruses. While the rise of antibiotics led to a decline in germicidal UV use, the 1990s saw a resurgence due to growing concerns over drug-resistant pathogens and hospital-acquired infections. This re-establishment of germicidal UV‑C among infection control preventionists underscored the wavelength’s ability to inactivate virtually any microorganism at the appropriate dose.

ASHRAE has recognized that UV‑C wavelengths can inactivate up to 90% of microorganisms living on HVACR surfaces, depending on the UV‑C intensity, exposure length, and operational conditions. More recently, the U.S. Centers for Disease Control and Prevention recommended UV‑C and mechanical HVAC filtrations as two primary technologies that can “improve air cleanliness in the workplace.”

Enhancing HVAC Efficiency and Energy Savings

Microbial and biofilm growth on HVAC components, such as coils and drain pans, can lead to coil fouling/clogging, reduce HVAC efficiency, and increase (fan/blower) energy consumption. The buildup of organic contaminants obstructs efficient heat transfer by creating an insulating layer on the coil, preventing warm air from effectively exchanging its heat with the coil.

By breaking down and removing organic buildup and biofilm from HVAC coil and fin surfaces, UV‑C energy helps preserve the coil’s “open area” — the interstitial space between the fins — ensuring strong airflow and maximizing heat exchange performance.

An ASHRAE field study found that exposing a fouled cooling coil to UV‑C improved heat transfer efficiency by 14.55% and decreased pressure drop (airflow resistance) by 10%. Other benefits include:

- Improved Heat Transfer: Clean coils facilitate better heat exchange, allowing the HVAC system to reach desired temperatures more efficiently;

- Reduced Pressure Drop: Eliminating microbial buildup minimizes airflow resistance, ensuring optimal air circulation and reducing the workload on fans and motors; and

- Lower Energy Consumption: Enhanced heat transfer and airflow efficiency reduce energy usage, leading to cost savings and a smaller carbon footprint.

The Importance of Timely UV Lamp Replacement

Germicidal effectiveness in HVAC applications depends on UV‑C energy and exposure duration.

Like any bulb, UV‑C lamps eventually burn out. However, only 20–30% of building engineers routinely replace their lamps. This happens for two key reasons: 1) UV‑C lamps are often installed out of sight in hard-to-reach air handlers, making maintenance easy to forget, and 2) engineers see the lamp’s blue glow and assume—incorrectly—that it’s still maintaining HVAC efficiency and improving IAQ.

A common misconception is that a bluish glow means a UV-C lamp is still effective, but visible light persists long after germicidal intensity drops below functional levels. The bottom line: Building engineers cannot rely on visual inspection to determine whether HVAC/R components are disinfected, as UV‑C energy is beyond the range of visible light, meaning you cannot see it.

Most lamp manufacturers (Signify, GE, Sylvania, etc.) recommend replacing UV‑C lamps after approximately 9,000 hours of operation, or, since there are 8,760 hours in a year, most facility managers employ an annual re-lamping / preventative maintenance schedule.

Replacing lamps when their output decreases by 20% is typical, usually occurring between 12-15 months. Lamp change-outs should be performed for mission-critical treatment, such as infectious disease or healthcare applications, using a calibrated laboratory radiometer or UV monitor.

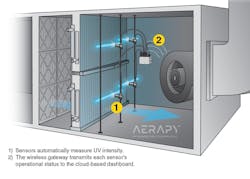

Advancements in UV Monitoring

Facility engineers increasingly use continuous monitoring systems and dashboard reporting metrics to streamline UV‑C HVAC maintenance.

If a lamp or ballast fails, the UV monitor alerts the user, helping ensure the application meets the UV output levels specified by design engineers or application requirements. Automating UV‑C monitoring also eliminates the need for facility managers to manually check individual lamps and ballasts. With UV‑C fixtures often spread across multiple HVAC AHUs, roof-top units, and locations, automated verification cuts labor costs and helps document operational or germ-inactivation efficiency. Most UV monitor interfaces and reporting dashboards easily integrate with building automation and management systems (BAS/BMS).

Key features of most UV monitors include:

- Predictive Maintenance and Automated Alerts: BAS/BMS-integrated UV monitoring enables predictive maintenance checks. Facility managers can receive automated alerts when a UV lamp is nearing the end of its lifecycle, reducing the risk of system downtime;

- Comprehensive Monitoring: Some UV monitors are equipped with sensors specifically configured for the UV‑C, LED-UV, and Far-UV wavelength, ensuring accurate detection of lamp performance across the spectrum;

- Prompt Alerts: UV monitors promptly notify users of any changes in lamp output, enabling timely adjustments and maintenance actions to sustain optimal performance.

UV monitors enable facility engineers and building managers to proactively manage UV‑C systems, ensuring consistent pathogen control and optimal HVAC efficiency.

UV monitoring systems align with the objectives of ASHRAE Standard 241, which establishes minimum requirements for reducing the risk of disease transmission through exposure to infectious aerosols in buildings. By ensuring that UV disinfection processes remain effective, today’s monitor technology consistently supports clean air and contributes to the overall health of building environments.

As clean air becomes a critical component of healthy, energy-efficient buildings, UV C technology and smart monitoring systems will continue to play a foundational role in the future of HVAC design.

Conclusion

By effectively disinfecting airstreams and preventing microbial buildup on critical components, UV‑C technology contributes to significant energy savings and reduced maintenance requirements. Adhering to a strict UV lamp replacement schedule of 9,000 hours or one year is crucial to maintain the specified UV‑C fluence necessary for effective disinfection. Furthermore, leveraging advanced UV monitoring systems ensures germicidal installations operate at peak performance, providing healthier and safer environments for building occupants.

About the Author

Annette Uda

Annette Uda is the president and founder of Aerapy UV Disinfection Technology. She is a corresponding member of ASHRAE TC-2.9 and ASHRAE SPC-185.2, both focused on Ultraviolet Air and Surface Treatment, as well as ASHRAE GPC 37, which addresses upper-air UV disinfection. She may be reached at [email protected].