Humidity Problems? Check For These Five Potential Suspects

Summer heat has returned, and with it, humidity complaints from your customers. As a technician, troubleshooting these calls can be both intimidating and frustrating if you don't know where to start and what to look for. If you find yourself in this situation, here are five potential suspects you can look for and eliminate one by one.

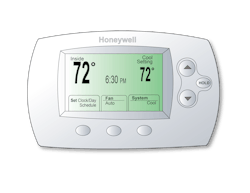

Thermostat in Fan-On Position

The easiest place to begin when you have a humidity complaint is the thermostat or controller. Check the fan setting to see what the homeowner or occupants have it set to. If it's in the fan-on setting, you may have found an easy fix.

When a fan runs constantly, it can reintroduce moisture into the airstream once the compressor shuts off and the indoor coil temperature rises above dewpoint. This situation is a surefire recipe for raising indoor relative humidity levels. If the equipment you're diagnosing has a draw-through air handler, the fan-on setting can also vapor lock the drain trap and prevent condensate from leaving the air handling equipment.

The solution for this issue is simple — advise the homeowner about the potential problems associated with leaving the fan in the on position and change the fan setting to auto. Let the fan run only when the cooling equipment is in operation and observe if the indoor relative humidity levels decrease. This may take a day or two since building materials act like sponges and absorb moisture. It takes time to dry these materials out.

Fan Speed Set Too High

The second place to check when there's a humidity issue is the fan speed setting. This check is essential on a gas furnace with a condenser or heat pump. In a world full of oversized furnaces, it's common to find blowers with too much airflow for the outdoor unit capacity. It's not uncommon to find a 100,000 Btu/h (British thermal units per hour) furnace with a five-ton blower paired with a three-ton outdoor unit or an 80k Btu/h furnace with a three-ton blower paired with a two-ton outdoor unit.

Fan airflow must be set to meet the outdoor unit's airflow needs. Many installations remain in the high-speed factory default fan speed setting, moving much more air than the outdoor unit actually needs. This condition results in poor dehumidification, low dry bulb temperature drops (ΔT) across the indoor coil, excessive noise, high total external static pressure (TESP), and potential for condensate blowoff from the indoor coil.

The solution for this issue is to adjust the fan speed setting to match the airflow requirements of the outdoor unit. If in doubt, set the blower for 350 cfm per ton if the indoor coil has a thermostatic expansion valve (TXV). Then, double-check the charge after making any fan speed adjustments. If the indoor coil has a fixed metering device, such as a piston, set the blower to 400 cfm per ton and follow the same steps to check the refrigerant charge.

Review Equipment Cooling Specifications

Once you've verified the proper thermostat and fan speed settings, it's a good idea to check the equipment's cooling specifications. Not all equipment removes the same amount of moisture. Depending on the equipment manufacturer, you may need to search online for the specifications.

Once you find the cooling specifications, there are three Btu types to review: sensible, latent, and total Btu. In cooling mode, you must account for all three, but when dealing with a humidity problem, focus on latent Btu. They are part of the moisture removal side of a cooling system. Sensible Btus are those you can feel, and they cause the temperature to change.

The equipment's latent capacity should be able to handle a building's latent Btu requirements as estimated by a Manual J load calculation. If the company you work for installs like-for-like-sized equipment or sells randomly sized inverter-based equipment as a silver bullet to skip the load calculation, you should have an "Oh crap!" moment. Why? Because you'll have no idea what the latent capacity target number should be.

If the equipment is oversized (and it probably is), it will never run long enough to dehumidify the building. The occupants can expect a cold, clammy, and miserable environment. Oversized equipment puts technicians in a tough situation, but it is easily preventable if HVAC companies do the right thing. You must address the solution before selecting and installing equipment by performing proper load calculations. Otherwise, you need to replace the oversized equipment.

Duct Leakage

Once you've cleared any equipment issues as potential suspects, it's time to look at other portions of the HVAC system that can influence humidity. Start with the duct system. Specifically, look for duct leakage. If any portion of the duct system is in an unconditioned area — like an attic or crawlspace — and there are leaks or disconnects, you have a recipe for uncontrollable humidity.

Return duct leakage in damp areas, such as vented crawlspaces, can pull moisture into the duct system and add a latent load for the cooling system to remove. Depending on the size and location of return leaks, the increased latent load may overwhelm the equipment's limited moisture removal capacity, rendering it incapable of removing the building's and occupants' moisture loads.

Supply duct leaks in unconditioned areas can create an airflow imbalance, pulling more air from inside the building than the duct system can supply. This situation causes pressure in the building to become negative, pulling it into a vacuum where it will attempt to draw air from wherever it can. These sources are often places you don't want to breathe the air from and can be loaded with hot, moist air.

The solution is to seal leaks and/or reconnect any disconnected ducts. However, before you do, it's best to measure the static pressure to ensure the TESP is within the manufacturer's specifications. Sealing systems with undersized ductwork running high static pressure will cause the TESP to increase, potentially leading to future equipment problems.

Room Pressure Imbalances

Other potential problems with either leaky or perfectly sealed duct systems are room pressure imbalances. As we just discussed, duct leakage can be one suspect that contributes to this problem. Still, there is another common issue causing imbalances — closing interior doors can cause significant changes in pressure.

Pressure imbalances occur when supply airflow into individual rooms is cut off from a central return once occupants close interior doors. If all interior doors are open, the problem is likely to disappear. Unfortunately, most customers don't live that way. They like their privacy, so they close their doors.

As most of you know, for each cubic foot of air (cfm) delivered into a room, there should also be the same amount of air returned. Let's say you have a main bedroom with 300 cfm delivered from the supply registers. That same volume of air should be pulled back into the return duct system. If there is a central return grille in another area of the home, closing the master bedroom door acts like a damper and blocks the pathway for the 300 cfm to return.

This single action changes pressures in both the primary bedroom and the main part of the building. The main bedroom pressure goes positive since air is being blown into that space, and the main part of the home with the central return goes negative. That return is still attempting to pull 300 cfm from another location and typically originates from a connection to the outdoors or an unconditioned space, such as an attic or crawlspace.

To discover and solve this problem, you'll need to measure room pressure with a micromanometer, such as the DG-8 from The Energy Conservatory (TEC). If the room pressure exceeds plus or minus three pascals, you'll need to relieve the pressure. You can use TEC's Roomulator as a guide to determine the required duct size to correct the problem.

The solution for each building will be different. If you're considering undercutting interior doors, don't waste your time. In many situations, it would be necessary to convert to saloon-style doors or bathroom stall doors to obtain the needed free area to relieve the room pressure.

Eliminate One Suspect at a Time

As you can see, some of these corrections are simple, while others can be more complicated and time-consuming. You may have noticed that as we progressed from one suspect to the next, the difficulty level and the cost of specialized test instruments needed to eliminate them increased.

Good troubleshooting is a systematic process of elimination, checking off one issue at a time until you find the guilty suspect. I've covered the five most common issues, but many others could be added to the list. I purposely left out dedicated dehumidification as a solution. However, it may be a necessity in some situations. If you've identified other issues contributing to high humidity, please email me. I would love to know what you are up against.

I hope this article has given you a starting point for identifying potential culprits and ways to determine which ones are terrorizing your customers. Remember that systematic troubleshooting leading to an accurate diagnosis is your best chance to resolve your customers' humidity problems.

About the Author

David Richardson

Director, technical curriculum

David Richardson serves the HVAC industry as director of technical curriculum at National Comfort Institute, Inc. (NCI), Avon, Ohio. NCI specializes in training that focuses on improving, measuring, and verifying HVAC and Building Performance.