Repair or Replace? Preparing for A2Ls in Residential Air Conditioning

Key Highlights

- Technicians must distinguish between different refrigerants, ensuring proper charging, leak detection, and component compatibility for both legacy R-410A systems and new A2L units.

- Handling A2L refrigerants requires specialized tools, leak detection devices, and safety measures due to their flammability classification, emphasizing the need for updated training and equipment.

- Existing R-410A systems do not need immediate replacement; however, future repairs and component replacements may be affected by new labeling and efficiency requirements for service parts.

A2L refrigerants have officially arrived in the U.S. air conditioning (AC) sector. Since January 2025, all new residential and light commercial AC equipment has been required to use refrigerants with a global warming potential (GWP) below 700. A2Ls have been listed as approved alternatives. As A2L-optimized units enter the marketplace, HVAC technicians will be among the first to encounter this equipment in new installations and system replacements.

The 700-GWP limit — which was mandated by the Environmental Protection Agency’s (EPA) Technology Transition rule under the authority of the American Innovation and Manufacturing Act (AIM Act) — will effectively prohibit the use of the legacy A1 hydrofluorocarbon (HFC) R-410A (2,088 GWP) in new AC equipment. The AIM Act also authorized the EPA to phase down HFC production and consumption, which aligns with a global timeline to reduce HFC supplies.

However, the transition to A2L refrigerants in the AC sector won’t happen overnight. Existing R-410A equipment will still need to be serviced for many years throughout their useful lifecycles.

When new equipment enters the field, it often comes with new installation and application considerations. During the transition from R-22 to R-410A, these dealt with the change in pressure. Today, it is flammability. Replacement fluids R-454B and R-32 have a “lower flammability” A2L classification. Thus, these applications have specific safety considerations and must use A2L-optimized equipment for installation and servicing.

For many years, Copeland has been working with original equipment manufacturers (OEMs) to develop A2L-ready equipment to meet new refrigerant mandates. With the GWP mandate impacting residential AC, technicians are encountering these units in the field. However, many have questions about installing and servicing new A2L systems while supporting customers with R-410A units.

Technicians must be prepared to provide homeowners with system repair and replacement options. To protect their hard-earned reputations, they must also ensure that the new equipment they specify will align with their high-reliability standards.

Balancing Old and New — A2L Servicing Implications

For HVAC technicians, the mix of already installed R-410A equipment and new A2L units will require the knowledge, tools, and resources to manage multiple refrigerants in the field simultaneously. As a rule, it’s important to remember that fluids and components are not interchangeable — both among new and legacy equipment and specific A2L refrigerant blends. For example:

- Do not charge an R-410A system with an A2L refrigerant (or vice versa);

- Do not charge an R-454B system with R-32 refrigerant (i.e., two different A2Ls);

- R-410A compressors or components are incompatible in an A2L-optimized system (and vice versa); and

- In A2L systems requiring leak detection, devices and/or sensors must be optimized to detect a specific A2L refrigerant (i.e., R-454B or R-32).

As with any new refrigerant platform, optimizing compressors for use with A2Ls requires various modifications and considerations, including lubrication, motor optimization, electronic componentry qualification, and material selection.

Repair or replace? Help Customers Make the Best Decisions

Your customers need to know that if their existing system is operating correctly, the EPA’s 2025 700-GWP limit does not require them to replace it. However, as the refrigerant transition progresses, the price and availability of HFC supplies may impact end users' “repair versus replace” decisions.

Helping your customers make this decision will be an essential part of your service offerings and an opportunity for you to add value as a qualified technician. Consider the following criteria in your decision.

Refrigerant and legacy component costs.

The price of R-410A is expected to rise over the next several years in alignment with the HFC phasedown. In turn, legacy component costs may also increase, as may potential challenges in sourcing these components.

Energy efficiency evaluation.

Estimate the energy efficiency and/or consumption difference between their legacy system and a new A2L system. A1 systems nearing the end of their lifecycles may experience efficiency losses, while new A2L systems provide higher efficiencies. Recent minimum system efficiency requirements by the Department of Energy (DOE) may also be a factor when evaluating legacy and new A2L systems. It may be beneficial to upgrade from an energy efficiency standpoint alone.

Available incentives.

Depending on the installation region and other factors, end users may be able to offset replacement costs with available incentives and tax rebates. Check state programs, federal tax credits, local utility incentives, and manufacturer rebates.

A2L Servicing Best Practices and Tools

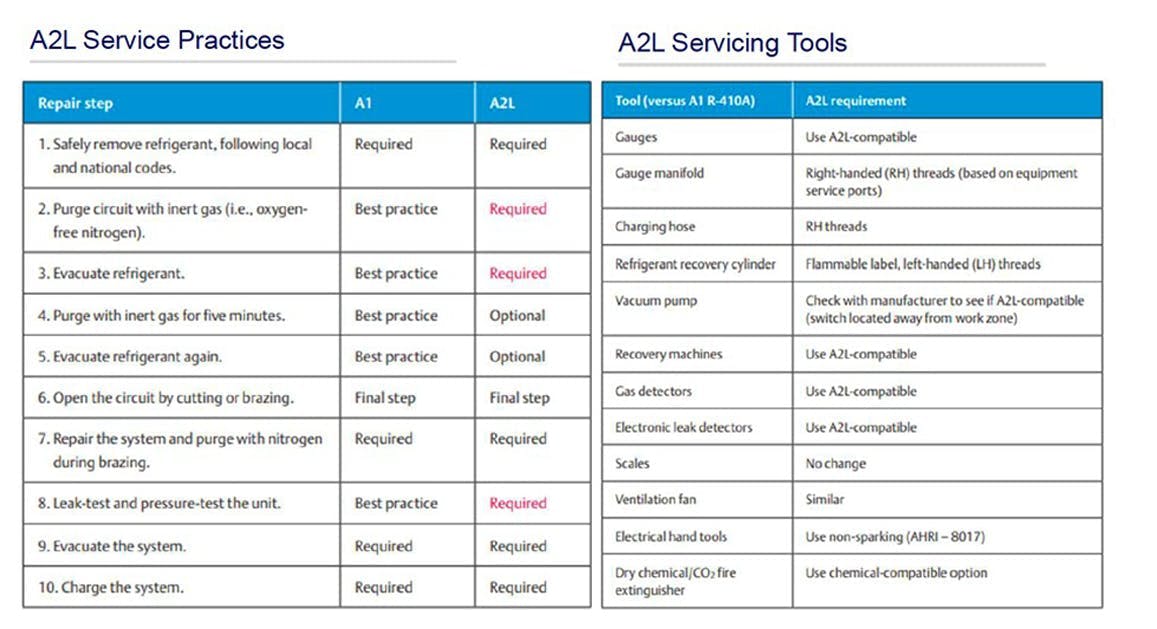

Despite any reservations and concerns about servicing A2Ls, specific best practices are the same as those currently used. Most are rules of thumb that technicians already know but have not always been required to follow with R-410A systems, including those listed in the table below.

Technicians must use only A2L-certified tools/gauges, replacement parts, leak detection, components, and compressors. Note that threading and labeling are unique to A2Ls to ensure differentiation from R-410A.

Be aware that mitigation measures, often including leak detection, will be mandatory on A2L units above ~4 pounds of charge. If needed, refrigerant detection devices and sensors will most likely be placed on or near the evaporator coil, where leaks commonly occur. Note: these devices and/or sensors must also be optimized to detect the system’s specific A2L refrigerant.

Understanding the Definition of a “New” System

Although system replacements are not required in residential air conditioning, some component repairs and/or modifications may qualify the system as “new.” For example, a complete system replacement (e.g., a condensing unit and an evaporator) would be considered new.

The EPA classifies condensing units, condensers, compressors, evaporators, and evaporating units as “specified components.” Beginning in 2025, these components may continue using legacy fluids such as R-410A to service existing systems, but must be labeled “for service only.”

In addition, the DOE requires replacement R-410A condensing units to meet federal minimum efficiency requirements under the Outdoor Unit With No Match (OUWNM) provision. The challenges and costs of meeting this requirement could significantly limit the number of R-410A outdoor condensing units manufactured in 2025 — or potentially eliminate that option altogether.

Note that this decision does not impact repairs of compressors, evaporator coils, and other components.

About the Author

Eric Strausbaugh

Eric Strausbaugh is the director of residential product marketing at Copeland.