I recently received an inquiry about a 2010 Hotmail article regarding energy savings from air balancing. Fast forward eight years and you’ll see vast industry improvements in our ability to save energy through testing, diagnosing, and upgrading HVAC systems. Let’s take a look at current data and see how much more energy you can save today using air balancing in your daily work.

In 2010, the best data we had reported 8% to 13% in available energy savings from air balance-related testing, diagnostics, and repairs. A recent study confirms the average savings today is three times what was earned only eight years ago.

What are Air Balance Tests?

Balancing has been our industry’s trusted test and verification method for more than 50 years. HVAC system balancing includes testing and adjusting the airflow, pressures, temperatures, fan speed, air volume dampers, and other devices to achieve intended performance. We then compare this information to designer’s and manufacturer’s specifications.

We use this same field information to diagnose system performance and isolate defects deteriorating system efficiency. The system is then upgraded so it can perform more efficiently.

New Energy Efficiency Study

Data gathered from more than 850 installed HVAC systems around the United States expanded on the original air balance tests to document and quantify installed system performance. Testing was performed before and after energy efficiency and comfort upgrades were made to the systems.

From these tests we learned the following:

- The average installed HVAC system performs at only 48% of the equipment-rated capacity. Delivered system Btus into the occupied space is compared to the equipment-rated Btu output.

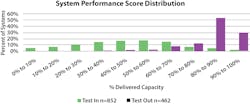

- The performance of unimproved installed systems varies widely from below 10% to above 90% (see green bars in chart below).

- Once improvements are made, performance increased to 83%. Most systems perform at 80% to 100% of capacity (see purple bars in chart below).

- From an energy efficiency calculation perspective, the study shows a 73% increase in cooling capacity after making system upgrades.

When you add system power consumption to the calculation, the result is measured installed system field EER.

- The average unimproved system in this study performed at only 6.7 EER

- Following energy efficiency and comfort upgrades, the average field installed system EER increased to 9.0.

- This shows a 34% net increase in energy efficiency.

The data indicates the amount of energy saved and a significant increase in cooling system capacity. This increases comfort in the home or building and overturns the old idea that comfort must be sacrificed to increase efficiency.

Additional Insight

Our understanding in many other areas of HVAC energy efficiency and day-to-day industry operations also improved from this study. We learned about different system defects that decrease efficiency and how to effectively repair them.

We saw motivated home and building owners eager to pay a higher price once they understood system performance and had confidence the contractor could repair the problems found. We also learned sales skyrocketed from the industry average of 20% to 30% to twice that rate when contractors use testing and diagnostics.

Sales Rates Increased -- Sales closing rates increased dramatically. Of the 852 systems tested, 462 systems were tested out at project completion. This means 54% of home and building owners chose to move forward with contractor recommendations and paid for energy efficiency and comfort upgrades.

Heat Transfer Issues -- After evaluating the pre and post-upgrade system test data, we discovered that poor temperature change through the system was the number one defect deteriorating performance. Causes included poor refrigeration circuit performance, duct system temperature loss, and duct leakage. Each defect can be repaired, once isolated by air balance and system performance testing.

Defects Affect Each System Differently

Armed with this information, it is clear that decades-old assumptions used by HVAC energy efficiency advocates need to be questioned. While decreasing static pressure is usually a good thing, the study revealed that this measure can increase efficiency by up to 40% on one system, yet only increase efficiency by 2% on another. As an industry, we should re-evaluate the idea of applying universal kW savings to measurements. This truth may be the root of the declining deemed-savings popularity in many of today’s utility programs.

With today’s skills, test instruments, and diagnostics, HVAC technicians can accurately detect and repair efficiency deterioration in each individual system. This is the new key to efficiency.

Finding and repairing defective equipment, restrictive and undersized air distribution systems, inadequate duct insulation, low and imbalanced airflow, and deferred maintenance does increase installed system efficiency, especially when we use field data to customize each repair.

Testing Alone Doesn’t Change Anything

Testing is the foundation for diagnostics. But testing itself doesn’t change anything. Testing coupled with technician knowledge enables accurate and customized diagnostics.

Systems can be redesigned and improved using time-proven field data and calculations. While some energy can be saved through adjusting systems, usually custom repairs based on good diagnostics are what save the most energy.

HVAC contractors who test, diagnose, and repair HVAC systems are first in line to benefit the most. The contractor is in the best position to offer customers the greatest energy efficiency. The rest of us are on the sidelines imagining what should happen, with little influence on field results.

Some may read this article and wonder why improved systems aren’t operating at 100%. The harsh reality is understanding what governs final system performance. It’s not the government, the equipment manufacturer, or a utility. It’s the customer.

Efficiency is controlled by home and building owner decisions made during their interaction with the contractor. No one else is as influential as the buyer and seller. The contractor decides on the scope of work through testing and conversations with the customer. The customer decides on the efficiency wanted and adjusts that level based on their budget.

Well-educated customers are the best customers. The best education, as confirmed by the data in this study, is accurate and clear field data shared with them. Valuable information about their own HVAC system enables them to make the best energy efficiency decision matching what they want and their budget.

Rob “Doc” Falke serves the industry as president of National Comfort Institute, Inc., an HVAC-based training company and membership organization. If you're interested in a summary of the study referred to in this article, contact Doc at [email protected] or call him at 800-633-7058. Go to NCI’s website at nationalcomfortinstitute.com for free information, articles, and downloads.

About the Author

Rob 'Doc' Falke

President

Rob “Doc” Falke serves the industry as president of National Comfort Institute an HVAC-based training company and membership organization. If you're an HVAC contractor or technician interested in a building pressure measurement procedure, contact Doc at [email protected] or call him at 800-633-7058. Go to NCI’s website at NationalComfortInstitute.com for free information, articles and downloads.