Service Clinic: Troubleshooting Zone Controls

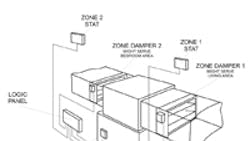

Although forced air zone control systems vary from one manufacturer to another, the principle of zoning is basically the same. A residential or light commercial zone control system uses multiple thermostats and motorized or pneumatic zone dampers along with a logic panel to control the air distribution from a single HVAC unit to individual zones. In most applications, a bypass damper is also incorporated to maintain the system static pressure as zone dampers open and close.

With proper testing, check, and start-up procedures, modern zone control systems require very little, if any maintenance after the original installation. Unfortunately, not every system is thoroughly tested to assure that everything is functioning properly. This usually leads to a user complaint after the installation is complete.

If the service contractor is not the original installer of the zoning system, he or she must first determine which brand of system was installed. The original manufacturer can then provide technical assistance and installation and operation manuals.

The zone thermostat on the wall is not necessarily the zone control brand. The user needs to determine the manufacture of the logic panel. The panel could be located on or near the HVAC unit, in a closet, garage, or attic. If they simply don’t know, or if locating the panel is too inconvenient, then the technician is making a blind service call. This is where basic understanding of zone control systems can be a real plus in the troubleshooting process.

Before heading for the jobsite, the service technician should make sure to have the following in the tool kit:

- quality multi-meter

- digital thermometer

- small screwdriver that fits electronic terminal blocks

- flashlight

- 18-gauge thermostat jumper wires.

Start at the Dampers

Most homeowner complaints are related to comfort level, and could originate in the zone thermostats, zone dampers, the logic panel, or even the HVAC equipment. A good start is to find out if the problem is isolated to one zone or multiple zones. If it’s a single zone, the diagnostic process becomes less involved. Typically, a single zone problem can be traced back to a malfunctioning zone damper or zone thermostat. Test the zone damper to see if it’s opening and closing properly, and replace and replacing any defective parts if necessary.

The second troubleshooting step for single zone problems is to test the thermostat. Adjust it to call for conditioned air to confirm that the zone control panel is receiving the correct corresponding signals from the thermostat. A jumper wire can come in handy here. To simulate a call for heat, disconnect the thermostats from the logic panel and place a jumper wire between the ‘R’ terminal and the ‘W’ terminal on one zone terminal.

This can help confirm that the logic panel and the HVAC equipment are working properly. Usually if a contractor can troubleshoot a thermostat that does not have zoning, they can troubleshoot a thermostat that does have zoning.

Multiple zone problems can be more complicated, but the troubleshooting steps are similar to a single zone problem. Isolating zone dampers and zone thermostats and testing each component individually should help you find the problem.