Servicing high-efficiency air-conditioning and refrigeration systems that use thermostatic expansion valves (TXVs) is a little more complicated than servicing older units that use fixed refrigerant-metering devices.

TXVs offer many operating advantages, but primarily have one function: the expansion valve meters the flow of liquid refrigerant into the evaporator in exact proportion to the evaporation rate of the refrigerant. It separates the high- and low-pressure sides of refrigeration on air conditioning systems. The TXV can control the gas leaving the evaporator at a predetermined superheat, which should remain constant.

Superheat is a way to ensure that the system is boiling off all of the liquid before it exits the evaporator. Refrigeration and air-conditioning systems may produce different superheat readings, but they are all determined the same way: by measuring indoor wet bulb and outdoor dry bulb measurements and using a pressure-temperature chart. In other words, superheat is the difference between two temperatures. Actual superheat is calculated from suction line pressure and temperature measurements.

The formula is:

suction line temperature – suction line saturation (boiling) temperature = actual superheat

Testing superheat must be done with the compressor operating in high-speed or high-stage. The advent of two-stage air conditioning compressors and variable-speed blowers can actually change some of the characteristics of the system, so always make sure you test TXV units in the high stage. In addition, take indoor wet bulb temperature measurements as close to the inlet of the evaporator coil as possible and as close to the center of the air stream as possible. Take the outdoor dry bulb temperature in the center of the inlet fins.

TXVs are reliable, but like any mechanical device, it’s possible for TXVs to suffer a mechanical breakdown—especially when they’re installed improperly.

There are three principle modes for TXV failure. Flooding is when the amount of refrigerant fed to the evaporator is more than can be evaporated, starving is when there is not enough refrigerant, and hunting fluctuates between too much and too little.

To operate properly, make sure that the sensing bulb is tightly secured to the suction line in the proper position. Generally, that means between the "10 o'clock" and "2 o'clock" positions, and make sure that it’s well-insulated. The bulb should not be influenced by any external sources of heat.

One common cause of problems is a low refrigerant charge at the sensing bulb. You check that by removing the bulb and holding it in your hand. If the suction pressure of the system doesn’t go up, suspect that the system or sensing bulb has a low charge. You’ll also want to make sure that a properly sized TXV is being used.

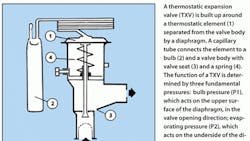

The pressure in the remote bulb assembly correlates to the refrigerant temperature leaving the evaporator. As this pressure increases, it tends to move the valve in an "opening" direction. Conversely, when the pressure decreases, it tends to move the valve in a "closing" direction. The valve will assume a stable position when these forces are equalized.

Failures can also stem from improper installation, specifically the failure to properly use nitrogen when braising the system’s refrigerant lines. R-410a systems operate at a much higher pressure than R-22 systems, and they have a much smaller orifice. Consequently, they’re not nearly as forgiving as R-22 systems, and a little bit of soot can create havoc. That’s why soot can be harder to diagnose; it can leave a TXV partially obstructed, which can lead to a starved evaporator. It’s very important to remove the sensing bulb prior to installing a coil with a factory-installed TXV.

The other big installation issue is failure to use a heat sink to prevent the internal mechanism of the valve from being damaged when it’s brazed into place. It is unlikely this would be the cause of your service call however, as the installer would know immediately that he had overheated the valve.

Remember that you’re there for a reason: a no-cooling call. So you want to be very prudent in your actions. Keep an eye on the system as you’re taking your superheat measurements. A system driving down into a vacuum is indicative of a TXV not opening, and most compressors are not very forgiving about being operated under vacuum for any length of time. You’ll be able to tell if the valve is hunting or not almost immediately at start-up.

Before you finish up, let the system run for at least 20 minutes to balance it out.

In conclusion, the key to servicing systems that use TXVs is to check the superheat. Many technicians have gotten away from that because systems can be charged using subcooling. Subcooling may be fine for charging, but it’s not a diagnostic tool like superheat.

Although you may still see some builder’s grade 13 SEER systems with fixed metering devices, systems above 14 SEER almost universally have TXVs. And while you’re servicing TXV systems, you can look toward the future and the growing use of electronic expansion valves, or EXVs. They offer extremely fine and efficient refrigerant control and — you guessed it — are even more sensitive to proper installation.

Jess Gordon is the service manager at Tempo Mechanical Services, Irving, TX. The company was Contracting Business magazine’s 2003 Residential Contractor of the Year. Jess can be reached at 972-579-2000, or by e-mail at [email protected].