While industry standards specifying ventilation rates are coming out of the woodwork, a practical standard describing how to measure ventilation airflows that can be applied in the field is hard to find. Let’s take a look at how you can determine residential and commercial exhaust fan airflow in the field.

Fans at Either End of the Duct

This may be obvious, but it is a good place to begin this discussion. Although in-line exhaust fans exist, most exhaust fans are found at either the start of a duct or at the end of a duct. This is a defining characteristic of some exhaust fans that affects the way we may determine fan airflow as compared to a forced-air system where fans are located between the supply and return ducts.

The Dangerous Assumption

Most standards are written to persuade designers to specify the needed airflow or air change rates. These standards require a calculation, and a specification requiring that the fan should do the job. With these tasks completed, most of the engineering world believes the standard is met and that ventilation needs are assured; dream on fellas.

The assumption that the fan and duct that were specified will do the job is far from realized. The design and specification must require that the ventilation system also receive the verification step of measuring, adjusting and balancing airflow by a qualified air balancer. Without this step the design is only a wish.

Typical Measurement Methods

There are many different types of ventilation systems and not all the required measurement methods can be discussed in a short article, so we will review the most common test methods.

1. Air Balancing Hood Measurement

If you’re lucky, and air exhaust fan airflow is being pulled from the room through a grille that is flat against a ceiling or wall, and the volume of airflow is between 30 and 2,000 CFM, use a calibrated air balancing hood. Set you the balancing hood to read in exhaust mode, securely place the hood over the grille to capture all of the fan airflow coming through the grille. Then read and record airflow.

Airflow specifications are plus or minus 10% of design airflow. With most smaller fans this spec is adequate. If you’re all caught up in exactness, forget about it. If you’re concerned about the determining the precise amount of duct leakage, your effort is better spent in installing the duct so that is doesn’t leak.

When airflow cannot be measured directly with a balancing hood, airflow can be measured in the exhaust duct by performing an airflow traverse.

RELATED: HOW TO DETERMINE EXHAUST FAN AIRFLOW

2. Traverse the Airflow in the Exhaust Duct

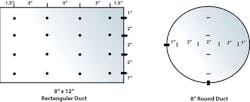

An airflow traverse requires at least 5 lengths of straight exhaust duct. Two or more 3/8-in. test holes are then drilled into the duct. An anemometer, a test instrument that measures air velocity is used to determine the average airspeed in the duct. Then the average feet per minute is multiplied by the area of the duct in square feet to determine the airflow moving through the duct.

Example: You have a bathroom exhaust fan designed for 200 CFM. The system has an 8-in. exhaust duct. The area of an 8-in. duct is .35 sq. ft. You measure the velocity at a points in the duct and find the average velocity in the exhaust duct is 400 FPM. Multiply 400 Feet per Minute times the area of the duct, which is .35 square feet, to find 140 CFM exhaust fan airflow.

3. Plot Fan Airflow

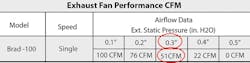

Each fan manufacturer publishes fan performance tables for each fan. Normally, these fan tables are shipped with the fan, or the information can be easily found online at the manufacturer’s website. In order to interpret exhaust fan airflow, you must measure the fan operating static pressure and the fan speed or Revolutions Per Minute. This field data is then used to plot fan airflow.

Smaller fans are often constant or single-speed. With these fans, you are not required to measure fan RPM. Larger fans require that you measure the fan RPM. This is normally done using a non-contact tachometer that reads RPM from reflective tape affixed to the fan.

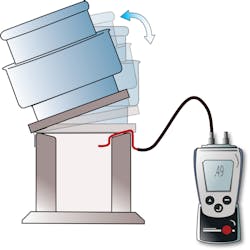

Fan static pressure is measured using a manometer (a pressure gauge) and a hose or tube and a static pressure tip. (See static pressure kit specifications available at the end of the article.)

Since many fans are located at either end of the duct, the operating fan static pressure is measured as air enters or exits the exhaust fan. Drill a test hole in the duct and read and record the fan static pressure.

Armed with the fan operating static pressure and the fan speed, go to the manufacturer’s fan table matching the fan being measured and plot fan airflow.

Draw a line intersecting the fan speed and the fan operating static pressure to reveal the fan operating CFM.

4. A Combination of One or More Test Methods

Because some fans are not installed suitable to measure fan airflow and because you are the judge and jury responsible to determine fan airflow, you will find times where you may employ two or more of the test methods above to gather sufficient data t render your judgment of operating fan airflow. The more data you gather, the more accurate your airflow decision.

Airflow Awareness

Just by becoming aware that airflow should and can be measured will get you in touch with the airside of the systems you design, install and service.

Reviewing the specifications of the fans you use regularly will make you aware of the limitations each fan has and the installation conditions that can cause fans to perform at 50% of the expected capacity.

The primary reason to measure airflow is for you to discover ventilation issues that your customers have been suffering from for years. Measuring exhaust airflow brings opportunity for your customers to receive improved ventilation and comfort. Opportunity comes your way through providing better service and increased earnings.

About the Author

Rob 'Doc' Falke

President

Rob “Doc” Falke serves the industry as president of National Comfort Institute an HVAC-based training company and membership organization. If you're an HVAC contractor or technician interested in a building pressure measurement procedure, contact Doc at [email protected] or call him at 800-633-7058. Go to NCI’s website at NationalComfortInstitute.com for free information, articles and downloads.