When you sell 18-SEER rated equipment, it’s a good thing. Let’s take a look beyond the yellow sticker and see how you can double the efficiency offering to your customers by assuring system efficiency matches equipment efficiency. Emerging technology provides you access to new opportunities for both you and your customers.

New Technology

I bought a new SUV this year. It seems each time I drive it, I discover how technology has advanced the ease and comfort of driving. My phone connects effortlessly to my car and sounds better than when it’s in my hand. If a car is in my blind spot, a yellow light in the mirror warns me. If I get too close to the car in front of me, I get yelled at. And my fanny even gets air conditioned through the seat. How I loved my heated steering wheel this winter! The new technology is wonderful and I benefit from it daily.

The ability to find and deliver new technology to customers is also available to each of you. However this technology is “outside the box” and beyond the efficiency that is inked on the yellow sticker.

An air conditioning and heating system is not a car that you drive off the lot with everything included in the package. HVAC equipment is like the engine which needs to be installed onto a chassis, then connected to the transmission, wheels, seats, windows and all the goodies we love so much.

De-Rated Efficiency

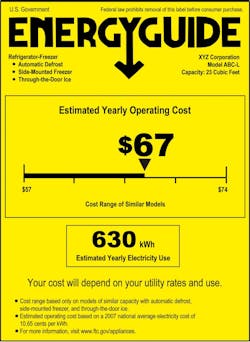

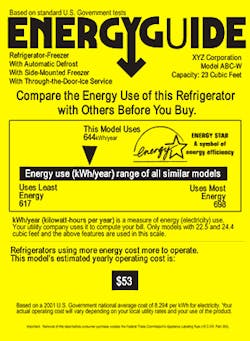

As an increasing number of contracting companies have discovered efficiency beyond the yellow sticker, there is a division forming at kitchen tables and business offices around the country as new and replacement HVAC systems are offered each day.One group is stuck on selling only the potential of the box efficiency printed on the yellow sticker. Their biggest mistake is representing equipment rated efficiency as the final measurement of efficiency.

The other group snatches the job almost every time by taking showing and explaining to customers that a laboratory efficiency rating is only the beginning of the efficiency story. Efficiency ratings are de-rated once equipment is installed in a building.

Customers know this is true because they have lived with a de-rated system for years. They quickly relate to the poor performance resulting from installation defects. The first group is quickly discredited and dismissed by the second group. The best part is, not one mean word is uttered against the competition, customer education does the job all by itself.

How Laboratory Equipment Efficiency is Determined

In cooling mode, efficiency is created using compressor mapping. These laboratory and modeled ratings often excuse such critical elements of reality as motor heat and coil pressure drop. Ratings assume ideal airflow through the equipment and often exclude any air distribution system losses that will inevitably be present in the field.

That’s like rating the efficiency of an engine before it is installed in the vehicle. Unfortunately, most HVAC systems are sold as the contractor quotes the equipment efficiency as the installed system efficiency. Shouldn’t there be a law against that?

In gas heating mode, a similar set of assumptions are also made in the lab. Efficiency is based on a number calculated through a combustion analyzer. Actual electrical measurements are excluded and efficiency credits are granted based on a pre-determined modeled scale for staging, modulation, ignitor type, and controls used.

System Measured Efficiency

Just as there are existing standards to support equipment efficiency ratings, similar principles and standards are being applied by savvy contractors to measure and rate the performance of an installed system in the field.

The problem is most utilities and regulators are stuck believing that wish-a-watt savings can only be synthesized in the lab. They fail to recognize that technicians and contractors on the front line have a greater ability to directly effect and increase efficiency because they are more face-to-face with customers than anyone in a laboratory ever can be.

Laboratory efficiency is determined by measuring airflow and temperatures. The same principles can be applied in the field. Even better -- the same measurements can take place throughout an installed system and be used to not only rate, but diagnose, and correct the issues causing the low system efficiency rating.

So the technology is available to measure and improve installed HVAC system efficiency. It is used daily to educate consumers and increase efficiency throughout the country. The days of selling yellow sticker efficiency are numbered.

Someday installed systems will require a disclaimer to protect customers -- advising them how much laboratory efficiency ratings are de-rated by installation. The current checklist method is like driving a ’57 Chevy, but not as much fun.

Today this technology is not yet accepted and recognized by those whose job it is to support and encourage advancing efficiency. That day will come slowly. The wheels are gradually beginning to turn.

Until that day, thank goodness the playing field will not be level and many of you will share an unfair advantage over your competitors.

Rob “Doc” Falke serves the industry as president of National Comfort Institute -- an HVAC-based training company and membership organization. If you're an HVAC contractor or technician interested in learning more about measuring installed system efficiency, contact Doc at [email protected] or call him at 800-633-7058. Go to NCI’s website at nationalcomfortinstitute.com for free information, articles and downloads.

About the Author

Rob 'Doc' Falke

President

Rob “Doc” Falke serves the industry as president of National Comfort Institute an HVAC-based training company and membership organization. If you're an HVAC contractor or technician interested in a building pressure measurement procedure, contact Doc at [email protected] or call him at 800-633-7058. Go to NCI’s website at NationalComfortInstitute.com for free information, articles and downloads.