For many years, duct leakage repair has been presented as the fix-all for HVAC distribution efficiency. The latest cry we hear now is for “Zero Duct Leakage.” This is being touted as the next big revolution for the HVAC industry to enlist in. Let’s take look at why we’ve gone about as far as we should with duct sealing and what other duct system opportunities deliver far more savings than super tight ducts.

Duct Sealing Often Reduces System Efficiency

There is no argument that duct leakage should be reduced. Nevertheless, there is a reason why an HVAC duct connection isn’t threaded like water pipe – the savings just aren’t worth the cost.

We’ve been so focused on tight ducts that we’ve completely missed other factors that deteriorate the efficiency and performance of duct systems. We’ve done so at the expense of our customers by not delivering the efficiency we’ve promised.

If you only make ducts tight, you decrease efficiency. That’s right. I felt a pain my chest the day I figured this out. Let me explain.

They typical residential duct system is way undersized. This is made evident by measuring air pressures in the system. The typical residential fan, rated at a maximum total external static pressure of .50,” operates in the field at a pressure of .82.”

That’s like having a blood pressure of 130 over 200. The resistance of airflow through the ducts is so high, the fan, that should be moving 400 cfm per ton, can only move 280 cfm per ton.

When a duct system is sealed, more air is forced through the duct system which increases system air pressures and further reduces system airflow. Typically, down to around 240 cfm per ton.

System operation conditions are so far below manufacturer specifications that it’s impossible for the refrigeration or heating circuit to perform properly. So, fan Watts increase on variable-speed fans, actual system efficiency drops, and delivery of heating and cooling to occupied space decreases. Comfort goes down and customer dissatisfaction goes up.

This is all accomplished in the name of energy efficiency.

Best to Seal Near the Equipment

The default test for duct efficiency is duct pressurization testing. This test produces a theoretical number, having little to do with actual duct leakage under live system operation. It assumes each leak, regardless of location, equally damages the efficiency of the system. That’s just not true.

In a live system scenario, you typically find static pressure near the equipment be .45” w.c. Pressure near the end of a duct is often .03” w.c. This coverts to 15 times more leakage through the same size duct leak near the equipment! Duct pressurization testing disregards this reality and focuses installation and repair crews on the wrong target. This has been going on for decades.

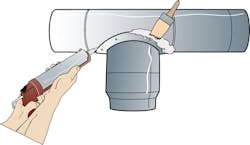

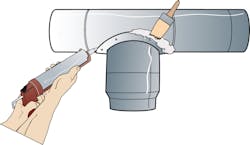

The amount of air moving through a duct leak results from the pressure difference across the leak. The greater the pressure difference from the inside to the outside of a duct, the greater the leakage.

For example, a 2-sq. in. duct leak near the equipment, where system pressure is the highest, may leak 40 cfm. But a 2-sq. in. duct leak near the end of the duct where system pressures are lowest may leak less than 3 cfm.

An installation or duct renovation crew that understands this principle, will focus their efforts on sealing high value leaks near the equipment -- often reducing duct sealing costs and labor by up to 80%. Plus, this still reduces overall duct leakage to a reasonable rate.

The remaining 80% of labor, time and material can be focused on much higher-value energy-saving repairs uncovered using time-proven HVAC testing and diagnostics.

These testing and diagnostics methods include live system duct leakage measurement, airflow diagnostics, static pressure profiling, and temperature problem-solving. The new generation of system upgrades pinpoint specific defects and enable precise, verifiable repairs that prove system improvement.

The Solution: Look Beyond Duct Leakage

Today you can measure the actual performance of an installed and operating HVAC system in the field. This ability didn’t exist when the idea of sealing ducts was first proposed. So it is important to step back and look beyond duct leakage.

Live HVAC system testing produces are a far more accurate assessment of the duct system and exposes needed custom repairs. This suite of tests quantifies the value of each repair and leads you to focus on the highest priority work.

You will find the typical unimproved HVAC system operating near 50 percent of capacity. This low score is caused by a variety of system defects not detected by duct pressurization testing. The corrections needed by each system are custom surgical repairs that can be completed for less cost. This is because they laser in on the specific problems causing efficiency losses.

After these custom repairs are completed, we’ve documented typical system performance improvement scores of more than 85%. Compare that to single-digit energy savings from duct sealing. That is a +30% measured improvement.

More Valuable Duct System Upgrades

Live HVAC system airflow, pressure, and temperature testing uncovers a new breed of custom repairs that deliver far greater savings and more desirable benefits to your customers than excessive duct sealing. For example:

- Airflow and static pressure diagnostics will lead you to find typical system airflow is only 60% to 70% of required system airflow. This low airflow is not just due to duct leakage, but more often due to undersized and poorly installed ducting.

This defect is corrected by adding additional ducts to relieve system pressures and increase system airflow.

- Air Filter restrictions are often excessive. This is caused by high efficiency filter replacements focused only on particulate removal and missing the negative impacts of reducing system efficiency.

By installing filters and filter systems with less resistance to airflow, particulate removal can increase and filter resistance to airflow can match the fan air-moving capacity.

- Adjusting fan speed to produce the required fan airflow is simple and significantly increases system efficiency. Keep an eye on the fan wattage consumption. It can completely undermine savings gained by increasing airflow.

- Duct system installation defects can be found by a combination of inspections and testing.

Disconnects can be connected, duct suspension can be added. Restrictive fittings can be replaced, pinch points and kinks can be corrected.

- Duct temperature losses are identified through temperature diagnostics. Loss of conditioned air temperature often reduces system efficiency by 10% to 20% when extreme temperatures are found in the duct space.

Additional duct insulation, often exceeding code requirements produce far more savings than excessive duct sealing.

- Once the distribution system is delivering design airflow, and only then, adjust the refrigeration and combustion circuits.

So the question for you is this: do you continue to take baby steps by crawling from 6% duct leakage to zero duct leakage for only a couple percent-points of energy savings at excessive costs to your customer? Or do you choose to leap forward a decade or two and embrace live HVAC system testing and repairs to increase system performance by 30% or more? The choice is yours.

Rob “Doc” Falke serves the industry as president of National Comfort Institute, Inc., an HVAC-based training company and membership organization. If you're an HVAC contractor or technician interested in a free test procedure describing simple testing you can do to diagnose your systems, contact Doc at [email protected] or call him at 800-633-7058. Go to NCI’s website at nationalcomfortinstitute.com for free information, articles, and downloads.

About the Author

Rob 'Doc' Falke

President

Rob “Doc” Falke serves the industry as president of National Comfort Institute an HVAC-based training company and membership organization. If you're an HVAC contractor or technician interested in a building pressure measurement procedure, contact Doc at [email protected] or call him at 800-633-7058. Go to NCI’s website at NationalComfortInstitute.com for free information, articles and downloads.