Heat Pump Defrost: Diagnosis

Heat Pump Basics

A heat pump is simply an air conditioner that can shift refrigerant flow to make the outdoor coil an evaporator, picking up heat from outdoors and the indoor coil a condenser, rejecting that heat indoors.

Many people object to the idea of a heat pump because it is hard for us to fathom that we can extract heat from the outdoors when it is so cold outside. The truth is that even at -30°, there is still a LOT of heat energy present outdoors that we can bring inside to the heat home. Absolute zero is −459.67°F (-273°C), which is the point at which heat no longer exists; until we approach that point, there is still plenty of heat to move around.

The basics of thermodynamics teach us that to move heat from one place to another, there needs to be a temperature difference. For us to get heat into the evaporator, which is now outdoors, we need to drop the temperature of that evaporator below the temperature of the outdoor air, in the case of an air to air heat pump.

This is a challenge in air source heat pumps because this required evaporator temperature is often well below the freezing temperature of water of 32°F (0°C), which means that ice can build up on the coils and prevent the movement of air and heat into the refrigerant.

This is why we need a defrost cycle and why we must learn how to test and diagnose heat pump defrost as HVAC service technicians.

Defrost Function● 4-way valve often called a reversing valve located near the compressor in the suction & discharge lines that reverses the direction of refrigerant flow.

● Thermostat designed for the additional O or B terminal to operate the reversing valve

● Extra control wires run to the condensing unit (generally five conductors minimum)

● An outdoor metering device dedicated to the heat mode evaporator coil

● Defrost controls

In cooling mode, most modern heat pumps require 24v from the O-terminal on the thermostat applied to the O-terminal or orange wire at the condensing unit to energize the reversing valve and hold the system in cooling mode.

There are still some systems that energize the reversing valve in heating mode using the B-terminal, but this has become relatively rare.

The heat pumps must have some method of periodically defrosting and this is done reasonably consistently across brands in the following way -

- The defrost control initiates the defrost on a time and temperature or demand basis

- The defrost board shifts the system from heat to cool modes, forcing hot gas from the compressor discharge into the frozen outdoor coil.

- The condenser fan is shut off to increase the speed of defrosting.

- The defrost board sends a 24v signal to the white wire, energizing W2 and bringing on supplementary heat if there is any.

Defrost Testing & Diagnosis

An excellent place to start before testing defrost is to read the manual from the manufacturer. Every modern heat pump manufacturer will have detailed instructions on how to test their product and is always the best place to start.

There are two strategies used most frequently in defrost, and we will cover both here.

Time & Temperature Defrost

The most common defrost method in heat pumps is the use of a timer and thermostat to initiate (start) the defrost and temperature to terminate (end) defrost.

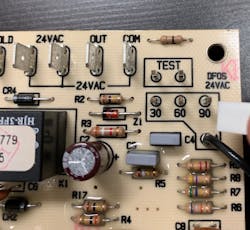

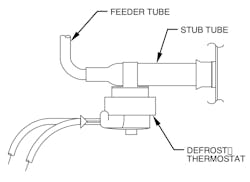

We will use a Carrier single-stage Comfort Series heat pump as our example. This system has a line thermostat, which is simply an open/closed bi-metal switch that attaches to an outdoor coil feeder tube, which closes at 30°F and opens at approximately 65°F. The defrost control board has a pin selection for 30,60 and 90 minutes between defrost.

Depending on how the pin is set, the defrost board will initiate a defrost every 30, 60, or 90 minutes IF the defrost thermostat is closed, meaning that the coil is below 30°F when that timer runs out.

From a practical standpoint, this should be most of the time since most customers won’t begin running the heat until low temperatures drop below 40°F, which is low enough for the coil to already be below that 30°F temperature.

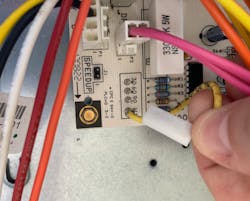

On this Carrier system, you can test this process by “speeding up” the board timer by placing a screwdriver or jumper across the speedup pins on the board. This will speed up the process by 25X, allowing you to test.

You still need the defrost thermostat to fall below 30°F to initiate the defrost, and if outdoor temperatures are well above 40°F, that can be tough.

An ideal method to test in these conditions is -

● Attach a K-type thermocouple or line temperature clamp near the defrost thermostat to monitor the temperature.

● Disconnect and tape off the lead going to the outdoor fan.

● Run in heat mode with the speedup pins jumpered.

● Confirm defrost

● Check to see what temperature the thermostat opens to confirm it is near the termination target.

Demand Defrost

Demand defrost uses two (or more) sensors; generally, thermistors, to monitor the air and coil temperatures simultaneously to check for the ideal times and duration for defrost.

I am using a common Trane heat pump strategy as an example. The board receives input from one outdoor sensor and one coil sensor, and initiates defrost based on the difference in temperature between them and terminates defrost based on the temperature of the coil sensor.

Testing can be done on this defrost via the force defrost or test pins, but manufacturer-specific guides should be consulted because specific programs can vary significantly.

The ultimate goal of defrost is to prevent the coil from becoming icebound with the fewest and shortest defrosts possible. If you walk up to heat pump covered in ice, you can bet there is an issue with the defrost control or sensors/thermostats, and hopefully, this gives you a clear place to start.

Bryan Orr is host of the HVACR Podcast, and HVACRschool.com.