1. Dirty Blower Wheels

A dirty blower wheel is the most common culprit. Think of each blower wheel vane like a shovel. When a shovel is clean, you can move a lot of dirt. However, you don't move as much dirt when the shovel gets compacted with mud.

Blower wheels "scoop" air from the return duct system and move it into the supply duct system. When vanes are clean, a properly designed and installed system moves the most air volume. However, if dirt compacts in the vanes, airflow decreases substantially.

It's estimated that a 1/8-in. coating of dust on blower wheel vanes reduces fan capacity by as much as 30%. As equipment airflow reduces, so does static pressure.

Remember this the next time you see air handler static pressure readings that look too good to be true. A quick blower inspection tells you a lot. If it's dirty, clean or replace it. Once the blower wheel is clean, you can remeasure static pressure. Don't be surprised if it changes.

2. Dirty Internal Coils

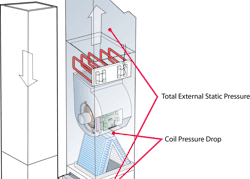

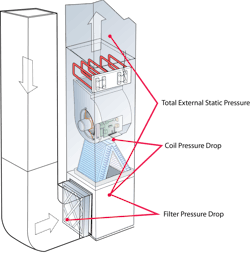

Rated TESP for most air handlers includes the internal coil as a factory-installed component. When the manufacturer's laboratory rates an air handler, the internal coil is new and clean. If the coil stays in that condition, your readings will be reliable.

However, your pressure measurements won't be dependable if the coil is dirty. In fact, your measured TESP will be very low, and you might assume all is well. This happens because the dirty coil pressure drop hides within the airTo overcome this issue, measure and document a "clean" coil pressure drop at startup after you set fan airflow. Write the coil pressure drop in permanent ink on the air handler. Internal coil pressure drop data is often unavailable for many air handler coils. Startup may be your only chance to document the clean coil pressure drop as a baseline for future diagnostics and maintenance.

If you're working on an older system with no information, there is a simple method you can use to estimate clean internal coil pressure drop. Multiply the maximum rated TESP found on the equipment nameplate times 40%. This gives you a target to aim for when you measure coil pressure drop.

If you're working on an older system with no information, there is a simple method you can use to estimate clean internal coil pressure drop. Multiply the maximum rated TESP found on the equipment nameplate times 40%. This gives you a target to aim for when you measure coil pressure drop.

For example, let's say the maximum rated TESP on the nameplate is .50 in. w.c. (inches of water column). Multiply .50 x 40% to find the internal coil estimated clean pressure drop equals .20 in. w.c. (.50 x 40% = .20). If you measure a pressure drop much greater than .20, inspect the coil and check its condition.

3. Factory Air Filters

Some equipment manufacturers include a factory air filter in their air handlers. If the manufacturer includes the filter from the factory, that means they also include it in the air handler's rated TESP. Although factory air filters are becoming much less common, you need to know the effects they can have on TESP readings.

Most factory filters have a low-pressure drop and don't affect your readings much. However, some can be restrictive. Including the filter pressure drop in your TESP measurement will cause the same results as a dirty coil. Your readings are not as good as they appear.

To keep it simple, treat the factory air filter as an external air filter. Don't get tied up trying to account for the factory-rated filter pressure when you measure — you'll end up pulling your hair out. Other variables can mess with your readings far more than this issue.

4. Modular Air Handlers

Modular (two-piece) air handlers differ from their single-piece cousins. The TESP rating in modular air handlers doesn't include the coil and filter. Instead, the blower is the only component included in the rating.

If you measure a modular air handler the same way you would a single-piece unit, the results can lead to a false sense of security. When you do this, the TESP reading does not see the coil and filter pressure drop. In the past, I've seen this cause technicians to miss their fan airflow estimations by as much as 500 cfm (cubic feet per minute) on five-ton air handlers.

The bottom line: make sure you know what type of air handler you're dealing with. If the cabinet is a single piece, it probably includes the coil in the pressure drop readings. However, if the installers had to fasten the blower cabinet and coil sections together, you must dig a little deeper to verify the air handler type. That leads us to the fifth point, 'footnotes.'

5. Ignoring the Footnotes

When you look in an air handler's installation instructions, find the accompanying fan performance tables. Inside there is an important section that accompanies these tables called footnotes. These footnotes provide information about how the equipment manufacturer rated the air handler fan. Don't ignore it.

If you dig deep enough, you will find the manufacturer-rated test conditions of the air handler. These conditions include whether the internal coil was wet or dry, filter velocity ranges, blower motor voltage ratings, and any included pressure drops. These footnotes are an essential reference for deciphering performance readings. Without them, you could miss the mark with your measurements.

Next Steps

If you're aware of these potential issues before you test air handler static pressure, it will help to minimize your mistakes. On your next call, track down the installation instructions for the air handler you're testing and locate the fan performance table and footnotes. Try to locate the information described above and write down what doesn't make sense.

If you can't find the manual, you can always try Google. I've had a lot of luck searching for the equipment manufacturer's name and the model number's first four to five digits. I can have the air handler fan table and footnotes in less than a minute on my iPhone.

Most manufacturers make their tables easy to understand. However, others are like ancient Egyptian hieroglyphics on a pyramid wall. Unless you research and try to use the information, you'll question your results. Gather all the data that you can so you can have confidence in your readings and your results.

David Richardson serves the HVAC industry as Director of Training for the National Comfort Institute, Inc. (NCI). NCIIf you're an HVAC contractor or technician interested in learning more about measuring static pressure, contact David at ncilink.com/ContactMe or call 800-633-7058.

NCI's website www.nationalcomfortinstitute.com is full of free technical articles and downloads to help you improve your professionalism and strengthen your company.

About the Author

David Richardson

Director, technical curriculum

David Richardson serves the HVAC industry as director of technical curriculum at National Comfort Institute, Inc. (NCI), Avon, Ohio. NCI specializes in training that focuses on improving, measuring, and verifying HVAC and Building Performance.