Duct System Assumptions to Duck on Equipment Changeouts

It’s unfortunate that some in our industry are comfortable attaching new, high-efficiency equipment to old, inefficient, and poorly installed duct systems. They just assume everything will work great. If you are one of them, there could be two massive duct system false assumptions you’re making. Let’s look at them and see what you might be missing.

Assumption Number One: The Duct Design is Correct

If you want to start a fight among HVAC contractors, ask them how to design a duct system. On one side of the discussion, you’ll have those who follow duct design rules of thumb that came from previous generations. Those “rules” probably came from their dad or someone else who taught them as they came up in the trade. To this group, disrespecting these rules is like spitting in the face of tradition and on the same level as insulting their mom.

Who was the original installing contractor responsible for the duct system that you attached the new equipment to? If they’re a contractor you badmouth for poor workmanship, congratulations – you just joined their club, because you now own their duct system.On the other side of the discussion are the duct design die-hards who follow industry-approved standards. They can quote the formulas and instructions from these standards by heart, and they have disdain for those who use rules of thumb. Duct design die-hards don’t understand why the rules-of-thumb group refuse to use industry approved methods and keep going back to the recommended residential setting on a duct calculator of .10-in. w.c. (inches of water column).

Depending on installation conditions, both groups could be right. However, they could also both be wrong. Design only tells you what the intended outcome of an installation should be. It doesn’t ensure the design will work. When you hook up new equipment to another contractor’s duct system, you assume they designed their ducts correctly.

Think long and hard about that last sentence and then think about the last equipment replacement job you did. Who was the original installing contractor responsible for the duct system that you attached the new equipment to? If they’re a contractor you badmouth for poor workmanship, congratulations – you just joined their club. Why? Because you now own their duct system.

A good design allows for the ducts to supply and return airflow from the air handling equipment’s blower at an acceptable static pressure. These ducts will also deliver the right amount of air to each room, but they aren’t self-balancing. So, if you believe a six-inch duct always delivers 100 cfm (cubic feet per minute) of airflow, you should reconsider.

Different duct sizes will deliver different airflow volume based on the length of the run and fitting types you use. But you must also consider the installation, because that’s what determines if the design will work in the field.

Assumption Number Two: The Duct Installation is Correct

If someone told you that your duct designs and installations didn’t work, could you prove them wrong? What could you do or say to defend your workmanship if someone questions the results? Holding your hand over the supply register and proclaiming it blows “good” isn’t enough.

Unfortunately, if a problem arises after you install a new air-handler or gas furnace to someone else’s duct system, you may need to provide proof of proper operation. While proper duct design is what should have happened, the installation is what really happened. It’s the finished product. A few factors to consider with an installation that’s put in correctly are:

- The ducts are tight and don’t leak air

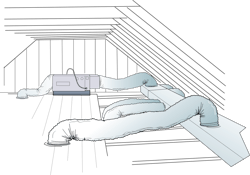

- All flexible duct is supported, straight, and tight, with no restrictions

- Duct fittings don’t create excessive pressure drops in the duct system

- Duct insulation prevents excessive temperature losses to unconditioned spaces like an attic or crawlspace.

When You Measure, You Know

You’ll never know how bad these assumptions are unless you test. If you don’t test, you’re blind to the results of installing new equipment to existing ducts. I once heard Rob Falke say, “If you don’t test a system you hook new equipment to, you’re no better than the installer who did it wrong in the first place.”

When you measure, you can be sure the right amount of airflow makes it to each room; you don’t have to guess. You will also know that duct pressures are within design parameters and not double what they should be. When you measure, you know.

Until I understood the concept of owning an existing duct system once I hooked up equipment to it, I never considered what I was doing. Once I was exposed to this line of thinking, it changed how I approached an existing installation. I had to ask myself, “Do you really want that unknown liability?”

Why would we take that chance and play Russian roulette with our systems? It was a game we used to playi. Sometimes we won and other times we lost. Then we learned a better way and started to test so we could verify the duct’s condition before we sold someone a new piece of equipment. We didn’t want it to perform poorly or fail prematurely. So, if there were issues, we made the homeowner aware of our findings and gave them options.

If you sell new equipment with the promise of efficiency and then attach it to an old, inefficient duct system, you have unintentionally deceived that customer. Instead, why not make sure you deliver systems you can prove work as designed? Your professional life gets easier when you don’t assume the existing installation works and adopt someone else’s problems.

David Richardson serves the HVAC industry as Director of Training for the National Comfort Institute, Inc. (NCI). NCI specializes in training that focuses on improving, measuring, and verifying HVAC and Building Performance.

If you’re an HVAC contractor or technician interested in learning more about duct upgrades the right way, contact David at ncilink.com/ContactMe or call 800-633-7058. NCI’s website www.nationalcomfortinstitute.com is full of free technical articles and downloads to help you improve your professionalism and strengthen your company.

About the Author

David Richardson

Director, technical curriculum

David Richardson serves the HVAC industry as director of technical curriculum at National Comfort Institute, Inc. (NCI), Avon, Ohio. NCI specializes in training that focuses on improving, measuring, and verifying HVAC and Building Performance.