The HVAC industry has some valuable history lessons to offer. Unfortunately, we tend to forget and don't pass them down. Some of us remember heat pumps from the late 1970s. They left a nasty taste in the mouths of many customers whose homes were freezing during an energy crisis. Twenty years later, ECM (Electronically Commutated Motor) technology significantly improved how we delivered and controlled equipment airflow. However, marketing presented ECMs as a remedy for poor duct systems that caused excessive breakdowns.

Both events hinged on significant technology changes that depended on proper duct system design and installation to work as intended. Our industry came up short in both instances. We will repeat history with the new inverter heat pumps unless we change how we approach the sales and installation process. In the short time inverter equipment has been available, the "way-we've-always-done-it" mentality has already given it a black eye.

It's time for mindset and skillset improvements to avoid the tough lessons history left as a reminder.

There is a better way to do business and ensure that new inverter heat pumps deliver as promised. However, we can't do what we've always done. It's time for mindset and skillset improvements to avoid the tough lessons history left as a reminder. Let's look at three steps to avoid repeating history and deliver better inverter systems.

Conduct a Customer Interview and Visual Inspection

If you're selling an inverter heat pump just for the spiff and a trip to the Bahamas, you're selling it for the wrong reason. Instead, start with your customer in mind. Find out their issues and what they want. They know their home better than anyone and can be a wealth of information. The more you include them in the inverter journey, the less likely you will experience an implosion.

First, find out what they like and dislike about their current HVAC system. What do they love, and what would they most want to change? Do they have any special needs or requests? As they answer these questions, take notes. They're describing their perfect HVAC system to you. If comfort and efficiency are their top replies, they're probably an excellent candidate for inverter equipment.

Once you've chatted with your customer, it's time to inspect the HVAC system and home visually. My buddy, HVAC contractor Vince DiFilippo, calls this "walking the ship." Visual inspections force you to take the time upfront and gather all the necessary information. You'll see many issues when you slow down and perform this step first.

Once you finish walking the HVAC side of the ship, it's time to focus on the house. This part of the inspection might not feel like your responsibility, but it is. If defects affect the HVAC system, you'll be blamed when comfort problems and excessive utility bills appear. Be sure to take notes and photos/videos of anything you find and address them with the customer. This information is also priceless in the design phase.

Evaluate the Duct System

You should reconsider if you're considering connecting a new inverter heat pump to the existing duct system and walking away. Instead, you must evaluate the duct system before connecting any new equipment to it. Check duct sizes, location, insulation, and sealing.

Once you complete the duct inspection, check the blower assembly and filter condition. A dirty blower tells you much about how well the homeowner cared for their HVAC system. If the filter location is somewhere your grandmother can't easily access, it's likely in the wrong spot. You immediately set yourself apart from competitors when you mention you could move it to a location that's easier to access. This relocation also allows you to increase filter surface area and efficiency to keep the new equipment clean.

After inspecting the ducts and equipment, it's time to test. Measure static pressure to get a feel for the existing duct systems' health. As mentioned in previous articles, this is the HVAC equivalent of measuring blood pressure. It can identify restrictions hidden during a visual inspection. If you're interested in the NCI Static Pressure Measurement Quick Start Guide, please email me a request.

If the system's TESP (Total External Static Pressure) is high, there's likely a duct system restriction that you should address. Additional static pressure measurements identify where the duct system restrictions are and help a homeowner understand why additional work may be necessary.

Static pressure without airflow only tells half the story. It's like checking refrigerant pressures without measuring the suction line and liquid line temperatures. You only have half the information you need to make an accurate diagnosis. Airflow measurement at the air handling equipment is a perfect addition to static pressure testing.

A direct measurement device like the Digital TrueFlow Grid from TEC (The Energy Conservatory) removes much of the guesswork. The accompanying app also generates a simple report that helps diagnose static pressure and airflow measurements in a customer-friendly, third-party report. These measurements show if the ducts in their current condition can handle the existing equipment size and required airflow.

Verify Equipment Sizing and Selection

Before recommending any inverter equipment, you need to know the proper equipment size and select it based on the home's heat loss and gain. If you only look at the existing model numbers and match up tonnage for the new equipment you're proposing, inverter systems will die prematurely. Also, the inverter's variable capacity isn't a green light to skip proper design.

At the bare minimum, perform an ACCA Manual J block load calculation to determine building heat loss and gain and derate the equipment using Manual S principles for your local climate. These two steps give you enough information to make an informed decision about the equipment capacity needs of the home and which equipment matchups best fit.

By the way, if you go any deeper into the home's design, be sure to get paid for your services. There's a big difference between doing a block load and derating the equipment versus performing the full ACCA residential design suite.

Recognize the Fork in the Road

If you made it this far, you should know what needs to happen based on the information you gathered. You'll find oversized equipment in many homes on an undersized duct system. If you do, you can connect the new, properly sized equipment (often downsized by one ton or more) to the existing duct system with minimal changes. But only if the ducts can handle the required airflow of the downsized equipment.

The other scenario is tougher. What do you do if you discover the existing equipment is properly sized but undersized ducts can't deliver the correct airflow? You have two options. Change the ducts to match the equipment size, determine how to reduce the building load, and downsize the equipment so the existing ducts will work.

As you can see, both models use an approach that many HVAC companies don't follow. Instead of racing to replace equipment with no regard for the duct system or building, this complete approach looks beyond the equipment.

This is not an approach everyone will use because it's different. You'll need courage and perseverance to master it. The other option is to remain stuck in our industry's outdated equipment replacement pattern. You won't learn the lessons of history, but your future is filled with dissatisfied customers and unhappy equipment manufacturers. This could have been avoided by talking with the customer, inspecting the entire system, and testing during sales.

Why not do the right thing and serve your customers well? Let them decide. It's your responsibility to provide them with the correct information and equip them with the knowledge to make an educated decision.

David Richardson serves the HVAC industry as Director of Training for National Comfort Institute, Inc. (NCI). NCI specializes in training focusing on improving, measuring, and verifying HVAC and Building Performance.

If you're an HVAC contractor or technician interested in learning about how to ensure your inverter installations don't implode, contact David at ncilink.com/ContactMe. NCI's website, www.nationalcomfortinstitute.com, is full of free information to help you improve your professionalism and strengthen your company.

Photo Captions

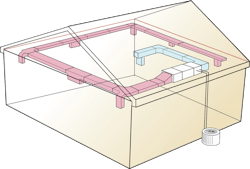

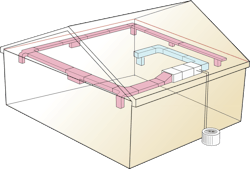

Photo 1: If you want to get an inverter system right, look past the HVAC equipment. The duct system and building are also essential components to consider.

About the Author

David Richardson

Director, technical curriculum

David Richardson serves the HVAC industry as director of technical curriculum at National Comfort Institute, Inc. (NCI), Avon, Ohio. NCI specializes in training that focuses on improving, measuring, and verifying HVAC and Building Performance.