Start Planting Better Buildings!

Working from home this past summer, my daughters would laugh when I'd shout, “My ASHRAE Journal’s here! My ASHRAE Journal’s here!” After five months of seeing the magazine in the mail, it had become a running joke.

I’m not an engineer, far from it; but over 15 years, I’ve come to appreciate mechanical systems engineering, and how ASHRAE presents its articles.

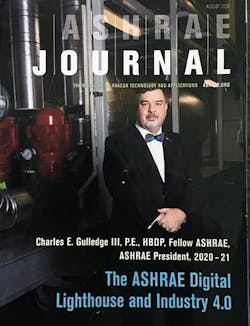

The August ASHRAE Journal was special. It featured the inaugural address of Charles Gulledge III, P.E., HBDP, now serving as the 2020-2021 President of American Society of Heating, Refrigerating and Air-conditioning Engineers, which we all know so well as ASHRAE. Our October cover story featuring this innovative thinker can be found HERE.

Waste in workflow is everywhere, and confusion often reigns on construction projects.

Chuck Gulledge is someone I hope to meet in person someday soon. I had never interviewed an ASHRAE President before, which is not to slight those who preceded Mr. Gulledge; it just so happened that this year, the opportunity presented itself. All incoming ASHRAE presidents deliver an inaugural message that sets the tone for their terms and describes what they hope to accomplish in the coming year.

The new process will involve tearing down some egos and elevating the importance of the end result and that of the team.

When applied to engineering and construction, plowing is assembling the correct team; planting is the well-defined path for the project; maintaining is bringing about continuous improvement to drive value; and harvesting is when you reap built solutions that exceed expectations.

Gulledge believes these critical steps are woefully absent from today’s E&C construction. Waste in workflow is everywhere to be found, confusion often reigns on construction projects, and many fields have to be plowed under and replanted over and over again due to rework.

The solution, Gulledge believes, is a digital innovation and restructuring of tasks, a breaking down of work silos into one integrated force. The entire process is presented in what he and ASHRAE call, “The Digital Lighthouse & Industry 4.0.”

The process will involve tearing down some egos and elevating the importance of the end result and that of the team. Technologies that must be employed at greater rates include drones, Internet of Things platforms, location detection technologies, 3D printing, smart sensors, augmented reality and “wearable” technologies, and many more.

In farming, Gulledge stressed, “You can't cheat the natural flow That's a very important statement to me. You cannot cheat the natural flow, and that applies to what we do in the E&C world.”

During our interview, I suggested that it seems to me that most contractors are still trying to get the hang of Building Information Modeling (BIM). Gulledge did not disagree, and acknowledged that some firms are still using CAD drawings and two-dimensional geometry. What’s missing he said, is “connected information”, and an elevation to 7D thinking.

The construction world’s vanguard, he said, are moving away from flat, 2D geometry, and away from points, lines and vectors, because the alternative is so much better.

With today’s astounding digital tools, Gulledge said, “We're able to virtually design and build a building, to see that it's going to fit, and this is where everybody's got to put stuff, and this is how it can be constructed. And then, we evolve to the schedule. We're getting labor issues tied into the content that's going into that model. And then we add the cost into it. Now, we can put schedule and cost as inputs to our design decision making. That is an incredible evolution for people.

That’s quite a mouthful, but Gulledge’s audience will get where he’s coming from. It means doing away with running models, spreadsheets, manual calculations and spider graphs.

“The ‘holy grail’ is when we move to the 7D level, where we connect operations and maintenance. We can present building owners with a living, breathing, virtual digital model of that building that is the basis for a digital twin that they live with forever,” he explained. “They don’t have to look for the IOM manuals or three-ring binder.

In farming, Gulledge stressed, “You can't cheat the natural flow That's a very important statement to me. You cannot cheat the natural flow, and that applies to what we do in the E&C world.”

Best wishes to Mr. Gulledge, and to ASHRAE, as they strive to nurture wider acceptance of Digital 4.0 and develop the training to help make it happen.