Key Highlights

- Following best practices in duct sizing and component selection leads to predictable, efficient, and quieter HVAC system operation.

- Using accurate math and Manual D guidelines is crucial for designing effective residential duct systems, rather than relying on rules of thumb.

- Component pressure losses from filters, coils, and grilles must be included in calculations to prevent airflow issues and noise problems.

Duct system design is challenging for most residential contractors, especially when you rely on rules of thumb. My friend and mentor, Ed Janowiak, manager of HVAC Design Education at Air Conditioning Contractors of America (ACCA), stresses the importance of correct math when designing residential systems to achieve “predictable results.”

What Causes Airflow Issues?

Years ago, when I was starting in the trade, I was taught that using a ductulator was the best way to size ductwork. I was also told by someone I respect that you should size residential systems with a 0.10-in. WC friction rate. Somewhere I have a ductulator packed away in storage with a note that says, “Recommended residential friction rate,” with an arrow pointing to 0.10. If my ductulator says this is the correct way to size ductwork, it must be true, right?

I have heard other variations of this rule of thumb. But no matter what random number you use on the ductulator, it will work until it doesn’t. Friction rate is a calculated pressure drop represented in inches of water column (in-w.c.) per 100 feet of duct length. The goal is to determine the correct size ducts so the fan can move the design airflow to all the areas of a home. You are putting yourself at risk of installing undersized ductwork whenever you use a random friction rate.

System Components are Often Overlooked

Air filters, hydronic coils, and evaporator coils are the most often overlooked components in a duct system. It’s easy to miss their resistance to airflow when calculating the required duct sizing friction rate. The pressure losses of these system components must be accounted for in the friction rate worksheet. The friction rate worksheet is a document in Manual D that provides guidance on what component losses to capture.

This means referencing manufacturer’s performance data and determining the correct airflow by following ACCA Manual S guidelines as a first step.

Coil manufacturers provide expanded tables of airflow (in cfm) vs. pressure drops, but air filters often have a different format. Although it is not uncommon to see air filter cfm vs. pressure drop tables, they may be displayed as air velocity (fpm) vs. pressure drop. This requires an additional step to convert your design cfm into velocity.

Another overlooked issue is incorrectly sizing supply registers and return grilles. These should be sized by referencing design cfm, throw, spread, and pressure drop, all while maintaining an acceptable noise criterion (NC) within the space (NC < 30 dB). If a grille or register is too small, it will have a high pressure drop, reduced airflow, and excessive noise. Do you have to turn up your television volume late at night when your furnace or air-handler turns on? Check your grilles and register sizing.

Sizing ductwork or calculating the friction rate without accounting for all component pressure losses may result in various issues. Some of these include:

- Improper airflow;

- Inadequate cooling;

- Objectionable noise;

- Increased motor watt draw;

- Increased duct leakage; and

- Reduced filtration.

Each of these issues can cause various comfort issues and premature equipment failure.

Start With the End in Mind

The end is design airflow. To determine cooling design airflow, follow the guidance in ACCA Manual S. This ensures the system’s Sensible Heat Factor (SHF) will meet the home’s Sensible Heat Ratio (SHR) requirements. To determine heating design airflow, refer to the furnace manufacturer’s airflow ratings that fall within their listed temperature rise range.

For both cooling and heating design airflows, refer to the equipment’s fan table and note the maximum external static pressure (ESP). It is best practice to use no more than 70% of the maximum ESP as a starting point when calculating the friction rate on a variable-speed blower.

For example, a variable-speed blower with a maximum ESP of 0.9 in. at the design airflow should not exceed a design ESP of 0.63 in.

0.9 in. x 0.7 = 0.63 in.

You can use an ESP at or below the maximum ESP for a constant-torque blower. For example, it is acceptable to use up to 0.9-in. ESP for a constant torque motor that has a maximum ESP of 0.9 in. at the design airflow.

Some furnaces may not allow you to use all the blower speeds for heating airflow, so pay close attention to the furnace’s capabilities when you determine a starting ESP.

Using Math to Account for Component Losses

After calculating the total component losses (TCL), deduct this from the blower ESP to determine the available static pressure (ASP), or ASP = ESP - TCL. Now use the friction rate formula to calculate the duct sizing friction rate.

Friction Rate = (ASP x 100) / (Total Effective Length (TEL))

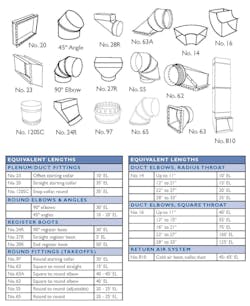

The total effective length, in units of feet, is the sum of all the individual duct fitting losses along the critical path. These losses are represented in straight feet of duct. In other words, a smooth, round elbow can be represented as having the same pressure loss as 20 feet of straight duct with the same airflow velocity. ACCA Manual D has duct fitting tables with corresponding equivalent lengths (ELs). These conservative values are based on the upper airflow velocity limits (900 fpm for supply fittings and 700 fpm for return fittings).

The critical path (CP) is the supply and return duct pathway, from the fan to the grille, that has the largest pressure loss in the duct system, or the longest TEL. This is usually the longest supply run and the longest return run, but not always. Once you have determined the critical path & TEL, all the ducts can be sized using the equal friction rate method. Some design software allows you to easily calculate the TELs of each branch, enabling individual friction rates for each duct circuit. This method is sometimes referred to as variable friction rate.

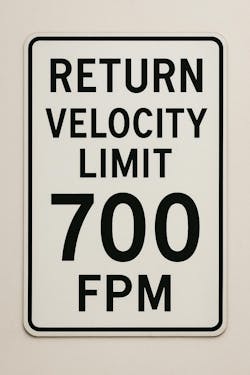

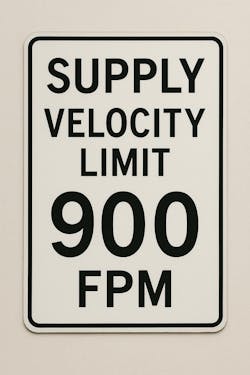

Don’t Break the Velocity Speed Limit

Manual D provides guidance not to exceed an airflow velocity of 700 fpm on the return side of the system and 900 fpm on the supply side. The first reason for this is that increased velocity also comes with increased noise. In other words, if you break the velocity limits, the airflow in the duct system may generate objectionable noise.

Another reason for the supply and return duct velocity limits is that the ELs listed in Manual D may no longer be valid, potentially resulting in an undersized duct system. Breaking the rules may result in reduced airflow, noise, or an imbalanced design that can be difficult to overcome.

A ductulator can be used to determine a duct's velocity, or you can use the following formula:

Velocity = CFM / (Area (sq. ft.))

Remember to divide the area, in units of square inches, by 144 to convert the area into units of square feet. Always pay attention to the velocity, even when using a calculated friction rate. If the calculated friction rate yields a velocity that exceeds the guidance in Manual D, increase the duct size to achieve a velocity at or below the maximum limits.

Designing a Duct System with Predictable Results

If you decide to use a calculated friction rate by using the friction rate worksheet in Manual D, it is not uncommon to find that your measured ESP of an installed system will be lower than what you designed for. This is a happy byproduct of rounding up to the next duct size using the calculated friction rate on your ductulator and the reduced pressure losses of duct fittings at velocities less than the maximum rated.

Following the airflow speed limits is also an essential factor when engineering a quality comfort system.

Many other best practices and tips are outlined in Manual D, and other engineering handbooks (ASHRAE, SMACNA, etc.) and are worth reading, but this article serves as the starting point to ensure that the system you install operates as designed.

About the Author

Adam Mufich

content developer and instructor

Adam Mufich serves the HVAC industry as content developer and instructor for National Comfort Institute, Inc. (NCI). NCI specializes in training that focuses on improving, measuring, and verifying HVAC and Building Performance. Find them at www.nationalcomfortinstitute.com.