Commercial refrigeration systems are essential to the preservation of vast amounts of food products, and/or pharmaceutical materials in research settings.Refrigeration failures, therefore, are costly in terms of lost product and business.

For that reason alone, every component must function precisely as designed. That includes defrost controls. Defrost controls prevent the build up of frost or ice from refrigeration system equipment and supporting component parts.

Electric or Hot Gas Defrost

The heat output that makes the defrosting possible is provided by either an electric or hot gas defrost system.

Defrosts can be programmed to occur automatically, or they can be performed manually.

Key parameters to any defrost event are of course time, temperature, and/or pressure set points. The setpoints control the defrost initiation start time and termination end time.

As the defrost heats the coil to remove ice, fans are on hold until the termination set point has been met.

While in the defrost mode, a safety interlock prevents the compressor and heat output from being energized simultaneously.

Defrost timers are used to shut off the refrigerator compressor and the evaporator fan motors. They turn on the defrost system at regular intervals to rid the evaporator of defrost.

How They Can Fail

Over time, the timer motor, motor bearing, or reduction gears on electromechanical timers can wear out. Signs of a problem can include:

- An occasional or persistent noise that comes from the part, or inconsistent defrost;

- It runs at some times but not others, which causes frost to build up on the gears or bearings and the timer stops rotating.

- The motor coil burns out and becomes an open circuit, and the timer stops rotating.

- Burned out contacts stick together.

Defrost Timer Troubleshooting Tips

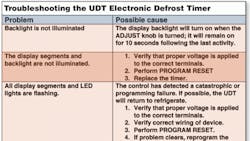

If the timer stops in run cycle, the refrigerator fails to automatically defrost, frost build up occurs on the evaporator, and air flow is restricted. If the timer stops during the defrost segment of the cycle, frozen food will be in danger of thawing out, and refrigerator components will cease to operate. See Table 1 below for a troubleshooting guide for a Paragon UDT electronic defrost timer.

Unit Cooler Troubleshooting Tips

Low temperature air travels through the unit cooler out into the refrigerated space. There are steps to follow when troubleshooting unit coolers. There are many steps to a correct diagnosis and service call.

- Observe unit cooler conditions and collect current operation information.

- Correct, unrestricted airflow is mandatory with all evaporators.

- Monitoring of suction pressure at the evaporator is necessary in order to correctly calculate superheat at the thermostatic expansion valve (TXV).

- Check proper flow supplied to the evaporator by the TXV and distributor assembly.

- The ability of the evaporator to efficiently exchange heat is totally dependent on having a fully active coil as near to saturated suction temperature of the refrigerant as possible.

- Remember: superheat can be correct with incorrect refrigerant distribution.

- Check electrical compartment for proper operation.

- Moisture build-up from all cold components can result in large ice or frost accumulation inside the compartment or conduit. This condition can affect defrost termination and fan control operations, which can leave defrost heaters operating longer than needed, resulting in heaters creeping or coming out of heater slots.

- Defrost heaters can suffer damage from ice or frost, which can in turn damage electrical wiring.

- Suction pressure, suction line temperature, liquid line pressure, liquid line temperature, and correct operating charge at the condensing unit are necessary to properly make a complete system diagnosis.

- Correct superheat range at the compressor is the only crucial superheat that really matters in refrigeration.

- Superheat at the compressor should usually be between 15 and 35F in order to protect the compressor from flooding or possibly, and more importantly, overheating.

- Superheat for scroll compressors should be between 10 to 20F.

- Frost at the compressor doesn’t necessarily mean low superheat, and no frost certainly doesn't mean there is sufficient superheat.

Dan Neumann is product manager, commercial refrigeration, Invensys Controls, Carol Stream, IL. He can be reached by email at [email protected].

Digital Controllers

Digital refrigeration and defrost controllers are used in self-contained refrigerated cases, and low or medium temperature applications.

Their control capabilities are many. They provide:

- Refrigeration temperature control

- Compressor or solenoid valve control

- Thermostat functionality

- Defrost control

- Optional evaporator fan control

- Optional alarm relay output

- Optional evaporator tempearture sensor for defrost termination and fan control

- Optional third temperature sensor

- Optional configurable digital inputs.

Shown is the Eliwell EW Plus 974 by Invensys Controls.

invensyscontrols.com

Circle 191

Defrost Timer Includes Power Loss Protection

The Paragon® 9045-00 and 9145-00 universal defrost timers from Invensys Controls Americas are engineered to refrigeration standards.

Features include: real-time clock, a15-minute manual defrost, system status indicators, a lighted display that shows defrost start time and duration, and 100 hours of power loss protection for both time and defrost schedules. The timers are certified to the UL873 standard for temperature-indicating and regulating equipment.

— Invensys Controls Americas

invensyscontrols.com

Circle 192

'Contractor Frendly'Defrost Timer

Intermatic's auto-voltage 40 AMP defrost timers — DTAV40 mechanical and the DTAV40E electronic are time initiated and temperature, pressure or time terminated. LED lights indicate defrost or refrigeration cycles. They automatically detect the appropriate supply voltage between 120 and 240VAC, replacing many voltage specific competitive clocks.

— Intermatic

intermatic.com

Circle 193